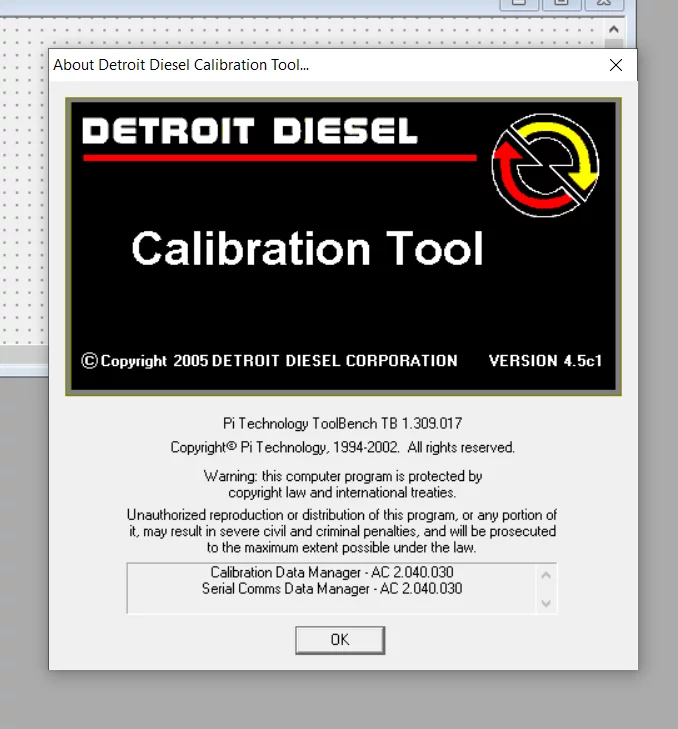

Detroit Diesel Calibration Tool DDCT 4.5: Optimize Your Diesel Engine Performance

The Detroit Diesel Calibration Tool 4.5 (DDCT 4.5) is essential for optimizing diesel engine performance. It provides users with the ability to view, edit, and monitor control parameters of the engine’s electronic control module (ECM). This tool features a user-friendly interface and supports both online and offline calibration. Its capabilities enable technicians to fine-tune engine settings, ensuring improved efficiency and compliance with operating standards.

Table of Contents

ToggleUnderstanding the Detroit Diesel Calibration Tool 4.5

This section delves into the functionalities and features of the Detroit Diesel Calibration Tool 4.5, offering insights into its integration with the engine control module and its advantages and limitations in diesel engine applications.

Key Features of DDCT 4.5

The DDCT 4.5 is well-regarded for its robust features that enhance engine management and efficiency. Some of the key features include:

- Programmable interface for direct interaction with the ECM.

- Real-time viewing and editing of critical engine parameters.

- Flexibility for both online and offline calibrations.

- Support for complex calibrations, accommodating various parameter types.

How the Tool Integrates with ECM

The integration with the ECM is seamless, allowing the DDCT 4.5 to pull critical data and modify settings directly. This connection is established via a diagnostic cable that links the software to the engine, facilitating easy access to vital metrics.

Once connected, adjustments can be applied immediately, making it easier to respond to engine performance issues in real time.

Benefits of Using DDCT for Diesel Engines

Utilizing the DDCT 4.5 provides numerous advantages for diesel engine management:

- Enhanced performance through precise adjustments of fuel mixture, timing, and other parameters.

- Improved fuel efficiency, which translates to cost savings over time.

- Reduction in harmful emissions, aligning with current environmental standards.

- Increased engine longevity when calibrated correctly, preventing mechanical issues.

Potential Drawbacks and Limitations

While the DDCT 4.5 offers significant benefits, users should also be aware of its potential drawbacks:

- The complexity of the tool may require a steep learning curve for new users.

- Improper calibration can lead to engine damage, necessitating advanced knowledge for effective use.

- Software compatibility issues may arise with older ECM models.

Installation and Setup Process

Setting up the calibration tool requires careful attention to detail. The following sections outline the necessary steps to effectively install and connect the software, as well as troubleshooting common issues that may arise during the setup.

Step-by-Step Installation Guide

To install the Detroit Diesel Calibration Tool DDCT 4.5, proceed with the following steps:

- Download the installation file from the official source.

- Double-click the downloaded file to initiate the installation wizard.

- Follow the on-screen prompts, including accepting the license agreement.

- Select the destination folder for the installation.

- Click ‘Install’ to begin the installation process.

- Once installed, restart the computer to finalize the setup.

Connecting the Tool to the ECM

After successful installation, connecting the tool to the Engine Control Module (ECM) is essential for calibration. The following steps should be followed:

- Locate the diagnostic port on the vehicle.

- Connect the calibration tool to the ECM using the appropriate diagnostic cable.

- Turn on the ignition without starting the engine to power the ECM.

- Open the DDCT software on the computer.

- Establish a connection by selecting the appropriate COM port in the software.

- Confirm that the software recognizes the ECM and is ready for data exchange.

Troubleshooting Common Setup Issues

While setting up the DDCT 4.5, users may encounter several common issues. Here are some solutions:

- If the software does not recognize the ECM, verify the connection and ensure the ignition is on.

- Check if the correct drivers are installed for the diagnostic cable.

- Ensure the software is updated to the latest version for compatibility.

- If the installation did not complete, attempt to run the installer as an administrator.

- For persistent issues, consult the user manual for advanced troubleshooting tips.

Using DDCT 4.5 for Engine Calibration

The application of DDCT 4.5 for engine calibration streamlines the process of optimizing diesel engine performance. This tool facilitates the precise adjustment of control parameters to achieve optimal functionality.

Viewing and Editing Control Parameters

DDCT 4.5 provides users with a comprehensive interface to view and edit various control parameters. This involves:

- Accessing critical settings, such as fuel injection timing and air-fuel ratio.

- Modifying diagnostic trouble codes and calibration settings according to performance needs.

- Utilizing intuitive graphical representations to analyze the engine data effectively.

Online vs. Offline Calibration

Calibration can be performed in two distinct modes: online and offline, each offering unique advantages.

Online Calibration

This mode allows for immediate changes while the engine is running, enabling real-time adjustments. Users can:

- Monitor engine responsiveness as modifications are applied.

- Make instantaneous corrections to improve performance based on the observed behavior.

Offline Calibration

In offline mode, users can prepare and modify calibration files without the need to connect to the engine. Key points include:

- Revising saved calibration files for different setups.

- Planning adjustments that can be tested once the engine is connected again.

Real-Time Monitoring Features

DDCT 4.5 excels in offering real-time monitoring features that capture vital engine data. This includes:

Instrumentation Variables and Controls

Users can track various instrumentation variables such as:

- Engine RPM and load.

- Detailed metrics on system performance and efficiency.

Fluid Temperatures and Pressures

Monitoring fluid temperatures and pressures provides critical insights to ensure optimal operation. This involves:

- Tracking coolant and oil temperatures.

- Observing fuel and oil pressure levels during different operational states.

Advanced Applications and Features

The Detroit Diesel Calibration Tool 4.5 offers advanced applications and features that enhance engine calibration processes and optimize performance capabilities. This section explores key functionalities that technical users can leverage for better results.

Debugging New ECM Control Logic

Utilizing the DDCT 4.5 allows technicians to debug and refine new electronic control module (ECM) logic. This feature is particularly beneficial when introducing updated programming or new functionalities to existing engines. By monitoring real-time data and comparing it against expected parameters, users can identify discrepancies and make necessary adjustments. Key steps include:

- Analyzing error codes generated by the ECM.

- Testing modifications through simulations before applying changes.

- Documenting performance changes to track improvements.

Fine Tuning for Optimal Performance

Fine tuning is essential for achieving peak engine performance. The DDCT 4.5’s capabilities enable users to adjust various engine parameters for specific operational conditions. This can result in:

- Improved fuel efficiency through better air-fuel mixture ratios.

- Increased power output while maintaining engine stability.

- Enhanced responsiveness during acceleration and operation under load.

Programmable Software Interface

The programmable software interface of the DDCT 4.5 allows for extensive customization options tailored to specific engine requirements. This flexibility is important for users aiming to adapt to unique operational environments. Features include:

- Creating custom calibration files for different engine models.

- Implementing user-defined logic for specific control strategies.

- Facilitating easy updates and modifications to existing calibration setups.

Maintenance and Best Practices

Implementing proper maintenance and best practices is crucial for ensuring the longevity and efficiency of diesel engines. Regular checks and adherence to guidelines help prevent potential issues and enhance performance.

Regular Calibration and Maintenance Schedules

Establishing a routine calibration and maintenance schedule is essential to keep the engine operating effectively. Recommended practices include:

- Conducting calibrations at regular intervals to ensure accuracy.

- Monitoring performance parameters continuously to identify deviations.

- Consulting manufacturer guidelines for specific maintenance recommendations.

- Using data logging features to track changes and outcomes for future reference.

These practices not only improve performance but also help in diagnosing issues early, potentially preventing costly repairs.

Ensuring Compliance with Warranty Policies

Compliance with warranty policies is vital to safeguard both the engine and any installed components. Adhering to the following aspects can ensure compliance:

- Following all manufacturer instructions during calibration to avoid voiding warranties.

- Documenting all maintenance activities, including dates, types of adjustments, and any parts replaced.

- Understanding the terms of the warranty to be aware of any restrictions regarding software modifications.

Proper documentation and adherence to guidelines help maintain warranty coverage while promoting optimal engine performance.

Frequently Asked Questions

This section addresses common queries related to the use and functionality of the calibration tool, providing clarity on essential aspects for users.

What is Remote Tuning and How Does it Work?

Remote tuning is a process that allows users to adjust the electronic control module (ECM) parameters from a distance. This is achieved through software and a stable internet connection, enabling technicians to make necessary changes without being physically present at the vehicle’s location. Typically, remote tuning involves:

- Establishing a secure connection between the technician’s software and the vehicle’s ECM.

- Conducting real-time data analysis to assess engine performance.

- Implementing adjustments based on specific performance needs or requirements.

How to Safely Use the Software for ECM Adjustments?

To ensure safe usage of the calibration software, several guidelines should be followed:

- Always back up the original calibration settings before making any changes.

- Familiarize yourself with the different parameters that can be adjusted.

- Conduct adjustments in a controlled environment to monitor changes effectively.

- Review any manufacturer guidelines to maintain warranty compliance.

Understanding the Refund Policy for DDCT 4.5

The refund policy for the Detroit Diesel Calibration Tool (DDCT) 4.5 typically outlines the conditions under which refunds may be granted. Important points include:

- Refunds may only be eligible if the software is returned within a specified period and is unused.

- Proof of purchase will often be required for initiating a refund request.

- Users should consult the official documentation provided at the time of purchase for detailed policy information.

CLAAS

CLAAS CNH

CNH

HITACHI

HITACHI

JPRO

JPRO KUBOTA

KUBOTA MAGIC TUNER

MAGIC TUNER

MANITOU

MANITOU

NEXIQ

NEXIQ NONSELF

NONSELF PACCAR

PACCAR

PSI POWERLINK

PSI POWERLINK

ZF TESTMAN

ZF TESTMAN