TRUCK SOFTWARE

CLAAS

CLAAS CNH

CNH

HITACHI

HITACHI

JPRO

JPRO KUBOTA

KUBOTA MAGIC TUNER

MAGIC TUNER

MANITOU

MANITOU

NEXIQ

NEXIQ NONSELF

NONSELF PACCAR

PACCAR

PSI POWERLINK

PSI POWERLINK

ZF TESTMAN

ZF TESTMAN

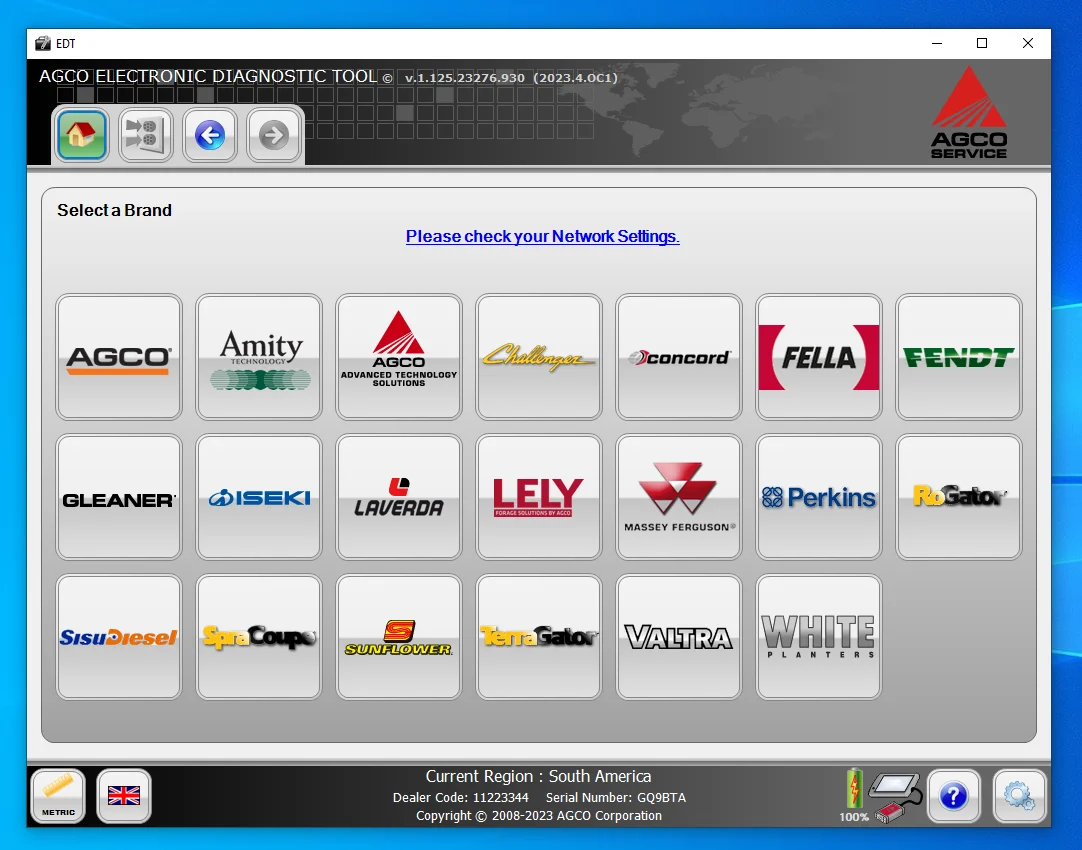

AGCO Diagnostic Tool 2023: Essential Guide for Efficient Farming

The AGCO EDT Diagnostic Tool 2023 is designed to enhance the efficiency of agricultural machinery maintenance. It provides essential diagnostic capabilities for various AGCO equipment, helping farmers minimize downtime and improve operational performance. This tool includes user-friendly features and access to critical information. With its intuitive interface, users can easily navigate through service manuals and error codes to support effective troubleshooting and repairs.

Table of Contents

ToggleUnderstanding AGCO Diagnostic Tool 2023

This section explores the key aspects of the AGCO Diagnostic Tool, highlighting its purpose, benefits, and main features that support efficient agricultural machinery management.

Purpose and Benefits

The AGCO Diagnostic Tool is designed to enhance the efficiency and reliability of agricultural equipment. Its primary purpose centers on simplifying the diagnostic process for operators, allowing them to identify and address issues quickly. The benefits include:

- Reduced downtime through timely diagnostics.

- Improved machinery performance and longevity.

- Access to comprehensive service information and error codes.

Key Features

This tool incorporates several key features that optimize its functionality:

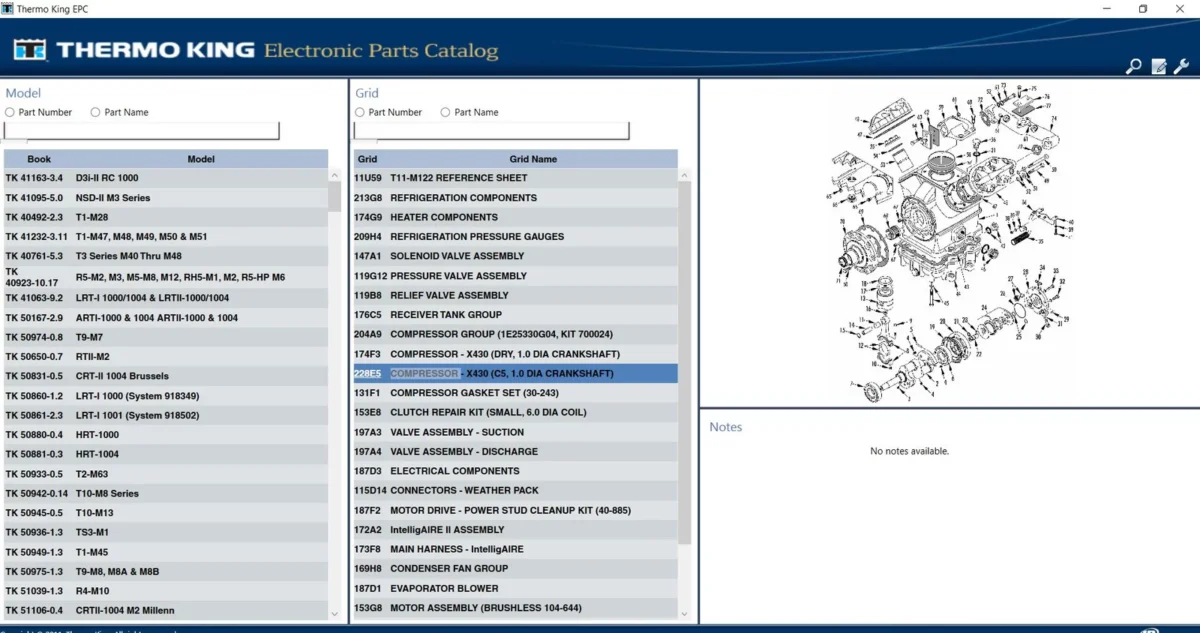

- Technical Information Access: Users can easily navigate manuals and service documents specifically tailored to their equipment.

- Diagnostic Functionality: Provides detailed diagnostics, allowing for precise troubleshooting of machinery issues.

- User-Centric Design: The interface is intuitive, making it accessible for users with varying levels of technical expertise.

Diagnostic Capabilities

The AGCO Diagnostic Tool offers advanced diagnostic capabilities essential for modern agricultural machinery maintenance. By utilizing electronic diagnostics, the tool streamlines the process of identifying and resolving issues efficiently.

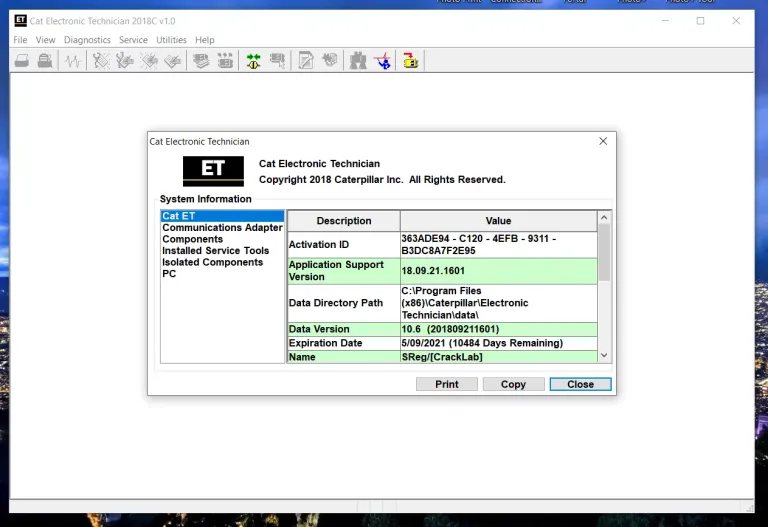

Electronic Diagnostics Overview

The tool provides a robust electronic diagnostics system that allows users to connect to their agricultural equipment easily. This system effectively analyzes various machine parameters to pinpoint potential malfunctions, ensuring timely repairs. Key aspects include:

- Real-time condition monitoring.

- Access to diagnostic reports and logs.

- Comprehensive scan capabilities for various subsystems.

Multi-Vehicle Access

A significant advantage of the AGCO Diagnostic Tool is its ability to support multiple vehicle types. This feature enables users to utilize the same diagnostic tool across different AGCO brands and models, enhancing operational efficiency. The benefits of multi-vehicle access include:

- Seamless transitions between machines.

- Centralized diagnostic management.

- Improved resource allocation for repairs.

Error Codes Interpretation

Effective troubleshooting relies on accurate error code interpretation. The AGCO Diagnostic Tool simplifies this process by providing detailed explanations of specific codes, assisting users in addressing issues swiftly. Key components include:

- Extensive database for error codes.

- Guidelines for troubleshooting common problems.

- Recommendations for necessary repairs and maintenance actions.

User Interface and Experience

The user interface of the diagnostic tool is designed to enhance the overall user experience, making operations more efficient and straightforward for users with varying levels of technical expertise.

Intuitive Design

The AGCO Diagnostic Tool features an intuitive layout that simplifies navigation. Key elements include:

- Clear visual indicators for different functionalities.

- Easy access to diagnostic reports and service manuals.

- Streamlined workflow to reduce the time spent on troubleshooting.

This design approach ensures that both seasoned technicians and new users can interact confidently with the system.

Using the CanUSB Interface

The CanUSB interface facilitates seamless connectivity between the machinery and the diagnostic tool. Key benefits include:

- Real-time data streaming for immediate diagnostics.

- Support for multiple AGCO vehicle platforms.

- Simplicity in setup, allowing users to get started quickly.

This interface significantly enhances the communication between equipment and the diagnostic application.

Navigating Service Manuals

Accessing detailed service manuals is effortless with the tool. Users can:

- Search for specific models quickly.

- Retrieve troubleshooting guides tailored to unique issues.

- Utilize interactive components for a more engaging experience.

This capability ensures that operational guidelines and solutions are always at the user’s fingertips, fostering a more productive maintenance environment.

Accessing the Diagnostic Tool

Accessing the AGCO Diagnostic Tool is a straightforward process that enables users to utilize its advanced features effectively. Below are the key steps involved in obtaining and setting up the tool.

Rental Periods and Options

Flexibility is a critical aspect when acquiring the AGCO Diagnostic Tool. Users can select from various rental options to suit their operational needs:

- One-month rental

- Three-month rental

- Six-month rental

This variety allows users to choose durations that align with their maintenance schedules or project requirements.

Setting Up Through Dealers

The setup process typically begins with engaging an authorized AGCO dealer. The steps involved in this process include:

- Consulting with the dealer about the rental agreement.

- Reviewing and signing the End User Agreement for Tech Connect Diagnostics.

- Providing necessary customer information, such as name and contact details.

Once the required paperwork is completed, the dealer will facilitate the necessary arrangements for tool access.

Tech Support and User Training

AGCO emphasizes the importance of user competence with the diagnostic tool. Therefore, technical support and training are integral components:

- Training sessions to support proper tool usage.

- Access to online resources for troubleshooting common issues.

- Dedicated support during the initial setup phase.

This ensures users maximize the effectiveness of the AGCO Diagnostic Tool for their agricultural machinery maintenance.

Compatibility with AGCO Brands

Understanding the compatibility of the AGCO Diagnostic Tool with various AGCO brands is essential for maximizing its utility. This tool supports a range of equipment, making it versatile across multiple agricultural applications.

Massey Ferguson and Valtra

The AGCO Diagnostic Tool is fully compatible with Massey Ferguson and Valtra models. Both brands are known for their reliability and advanced technology. The diagnostic capabilities enable users to identify issues efficiently, ensuring optimal performance.

Fendt and Challenger

Fendt and Challenger tractors also benefit from the diagnostic features provided by the AGCO Tool. These brands are recognized for their high-performance machinery. The tool aids in diagnosing complex systems, allowing for timely maintenance and reduced downtime.

White Planters and Other Brands

In addition to the previously mentioned brands, the AGCO Diagnostic Tool is compatible with White Planters and various other AGCO machinery. This broad compatibility helps streamline diagnostic processes across different equipment types, enhancing overall agricultural efficiency.

Maintenance and Repair Strategies

Effective maintenance and repair strategies are crucial for optimal machinery performance in the agricultural sector. Utilizing advanced diagnostic tools ensures timely interventions and prolongs equipment lifespan.

Preventive Maintenance with AGCO Tools

Preventive maintenance is an essential practice that involves regularly scheduled inspections and servicing of machinery. Implementing this strategy can lead to the following benefits:

- Reduction in unexpected breakdowns.

- Improvement in overall equipment efficiency.

- Extending the lifespan of agricultural machinery.

Using AGCO tools allows for systematic tracking of maintenance activities, ensuring that all necessary tasks are performed on time.

Real-Time Network Analysis

Real-time network analysis provides insights into equipment diagnostics and performance. This capability allows operators to:

- Quickly identify issues as they arise.

- Monitor the health of various machines simultaneously.

- Make informed decisions regarding repairs before minor issues escalate.

Utilizing this feature supports proactive management of agricultural equipment.

Efficient Repair Procedures

Implementing efficient repair procedures is critical for minimizing downtime. The key components include:

- Utilizing detailed service manuals available through AGCO.

- Training staff on standard repair protocols.

- Employing advanced diagnostic tools to guide repair efforts.

These practices ensure that repairs are conducted swiftly and accurately, allowing for a return to optimal productivity.

Supporting Information and Resources

Accessing supporting information and resources is vital for maximizing the effectiveness of agricultural diagnostic tools. These resources provide essential guidance for users in understanding and utilizing the AGCO Diagnostic Tool effectively.

Service Information Access

Users can obtain comprehensive service information through various platforms. This access includes:

- Detailed service bulletins that address specific issues.

- Up-to-date software updates to enhance tool functionality.

- Guidelines for troubleshooting common equipment malfunctions.

Workshop and Product Manuals

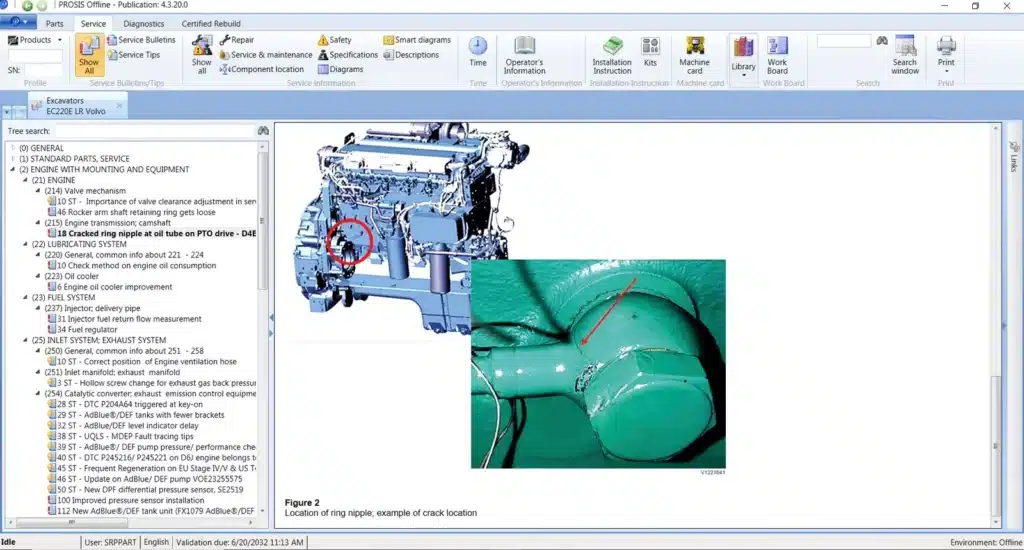

Workshop manuals and product guides are crucial resources for operators. These manuals typically contain:

- Step-by-step repair procedures for various AGCO models.

- Operational tips and maintenance schedules to ensure longevity.

- Identification of key components and their functions for effective diagnostics.

Online Support and Contact Info

Online support is available for users seeking assistance with the AGCO Diagnostic Tool. This can include:

- Accessing FAQs that cover common inquiries.

- Utilizing forums for community-based support and sharing experiences.

- Finding resources and documents available for download to aid in diagnostics.

Future Trends in Agricultural Diagnostics

As technology continues to advance, the agricultural sector is witnessing significant changes in diagnostic practices. These trends are shaping the future of machinery maintenance and efficiency.

Innovations in Diagnostic Software

The next generation of diagnostic software is focused on enhancing user experiences and improving accuracy. Innovations include:

- Artificial Intelligence (AI) integration for predictive analytics.

- Mobile compatibility, allowing diagnostics on-the-go.

- Cloud-based solutions for real-time data access and sharing.

- Enhanced user interfaces for simplified navigation and analysis.

These advancements aim to empower users with deeper insights, ultimately leading to better decision-making in maintenance and repairs.

The Role of AGCO in Global Farming

AGCO is not just a leader in agricultural equipment; it plays a crucial role in shaping global farming practices. Key contributions include:

- Developing sustainable farming technologies that reduce environmental impacts.

- Collaborating with farmers to understand their needs and challenges.

- Investing in research and development to foster innovation.

- Providing extensive training and resources to ensure effective tool utilization.

With these initiatives, AGCO is paving the way for more resilient agricultural practices around the world.

FAQ and Common Inquiries

This section provides answers to frequently asked questions regarding the AGCO Diagnostic Tool and its usage. It addresses common problems, ways to enhance operational efficiency, and available customer support options.

Troubleshooting Common Issues

Users may encounter various issues when utilizing the AGCO Diagnostic Tool. Here are some common problems and their solutions:

- Inability to connect to the diagnostic software: Ensure the CanUSB interface is properly connected.

- Incorrect error codes: Verify that the machine is compatible with the diagnostic tool.

- Slow performance: Check for updates to the software to enhance functionality.

Maximizing Tool Efficiency

To achieve the best results from the AGCO Diagnostic Tool, consider the following tips:

- Regularly update the diagnostic software to access new features and fixes.

- Practice using the tool with simulations to become familiar with its interface and functions.

- Utilize comprehensive service manuals available through the platform to enhance understanding.

Customer Support Channels

AGCO provides various support channels to address user concerns:

- Online forums: Community support is available for sharing experiences and solutions.

- Technical support teams: Dedicated personnel can assist with troubleshooting issues.

- User training sessions: Regular sessions are offered to improve proficiency with the diagnostic tool.