Diesel Diagnostic Link DDDL 8.17: Your Essential Tool for Diesel Engine Diagnostics

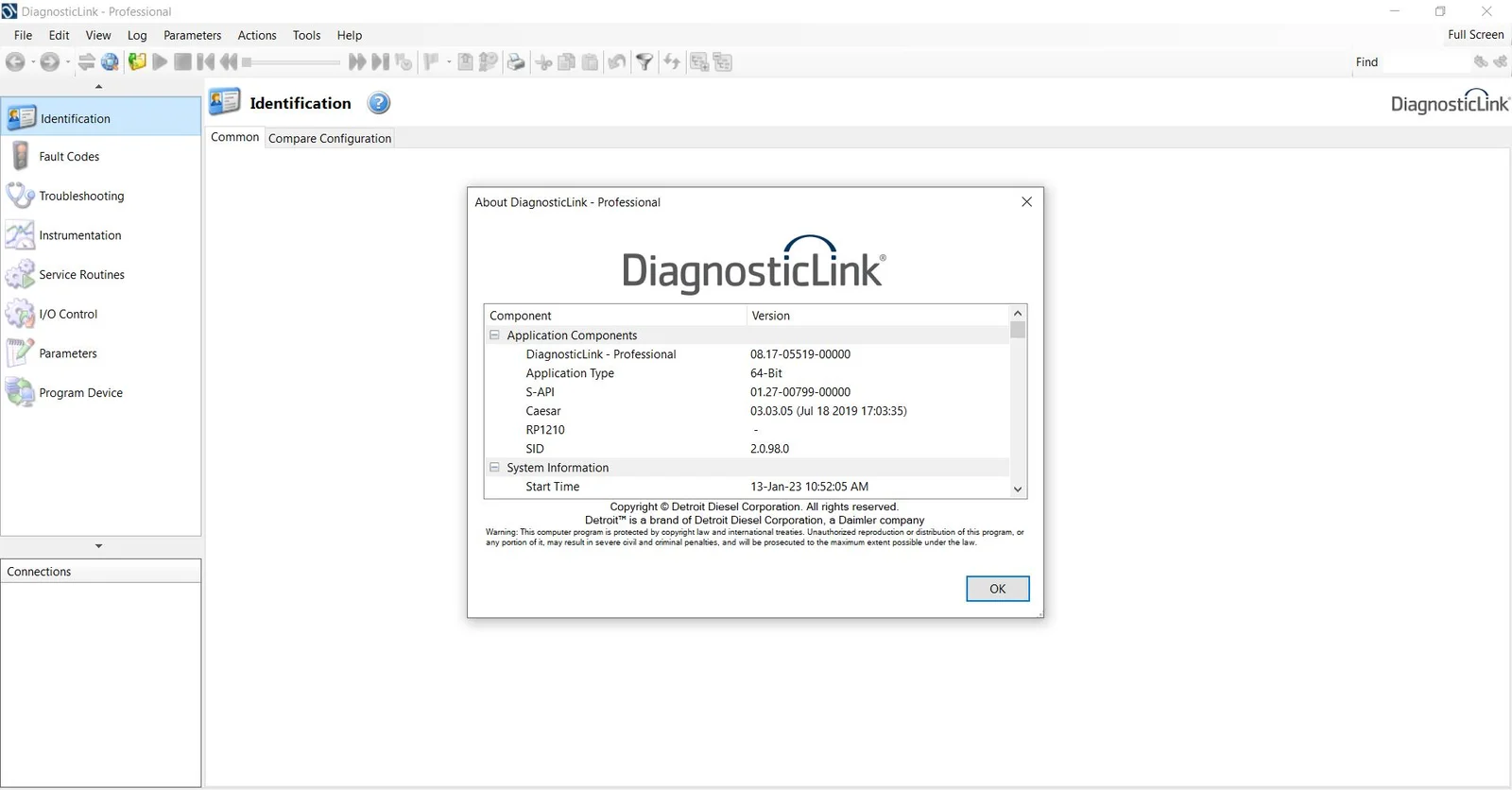

Diesel Diagnostic Link DDDL 8.17 is an essential tool for diagnosing diesel engines, particularly those from Detroit Diesel and Freightliner. This software facilitates quick and accurate troubleshooting, making it vital for automotive professionals. The latest version enhances user experience with advanced diagnostics and reprogramming features. It is designed to help technicians maintain compliance with environmental regulations while optimizing engine performance.

Table of Contents

ToggleUnderstanding Diesel Diagnostic Link DDDL 8.17

The Diesel Diagnostic Link DDDL 8.17 is an advanced diagnostic tool designed for professionals working with diesel engines. It provides essential functionalities to ensure effective engine management and maintenance.

Origins and Evolution

Developed by Detroit Diesel, the Diesel Diagnostic Link has undergone significant evolution since its inception. This evolution reflects the growing complexity of diesel engine systems, driven by stricter emissions regulations and advancements in automotive technology. The DDDL 8.17 is the latest iteration, showcasing improved performance, enhanced user interface, and refined diagnostic capabilities.

Key Features

DDDL 8.17 comes equipped with a variety of features tailored to meet the needs of diesel engine technicians. These key components are critical for efficient diagnostics and repairs.

ECU Information Access

This feature allows technicians to gain real-time access to the Electronic Control Unit (ECU) data. Understanding ECU parameters is crucial for pinpointing issues quickly and accurately, leading to more effective troubleshooting.

Diagnostic Fault Codes

The software can read and interpret diagnostic fault codes generated by the vehicle’s ECU. By displaying these codes, DDDL 8.17 facilitates rapid identification of potential problems within the engine and its components.

Service Routines

It incorporates predefined service routines that technicians can execute as part of maintenance or diagnostic procedures. These routines help streamline the workflow, ensuring essential checks are performed routinely.

Reprogramming Capabilities

One of the standout features of DDDL 8.17 is its reprogramming capability. Technicians can reprogram electronic components, thus optimizing engine performance and addressing specific issues that may arise over time.

Functional Tests

The software supports a range of functional tests that allow technicians to assess the various systems within the engine. This includes checks for fuel injectors, turbochargers, and emission systems, ensuring each component operates as intended.

Compatibility and System Requirements

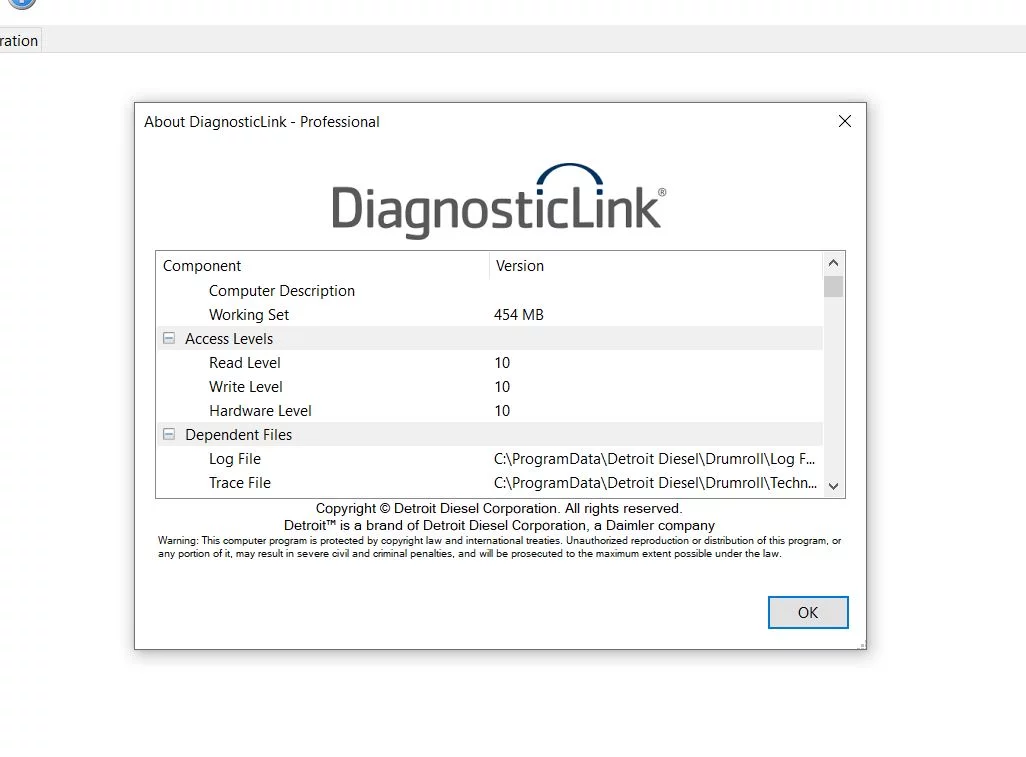

Ensuring compatibility and meeting system requirements is essential for optimal performance when using diagnostic software. The Diesel Diagnostic Link (DDDL) 8.17 requires specific configurations to function effectively, which include both operating system and hardware considerations.

Operating System Compatibility

DDDL 8.17 SP1 is designed to work seamlessly with modern operating systems. The following are recommended for installation:

- Windows 10

- Windows 11

The software may not operate correctly on older versions of Windows. Ensuring the use of supported operating systems enhances reliability and user experience.

Hardware Requirements

Particular hardware specifications are critical for running DDDL 8.17 smoothly. Users are advised to meet the following requirements:

Processor and RAM

A capable processor and sufficient RAM are necessary for efficient operation:

- A dual-core processor with a minimum speed of 2.0 GHz is recommended.

- At least 2 GB of RAM is required, though 4 GB or more is suggested for optimal performance.

Disk Space and Screen Resolution

Ample disk space and appropriate screen resolution are vital for installation and usability:

- The software requires around 40 GB of disk space, with a minimum of 20 GB available for installation.

- A monitor with a resolution of at least 1024 x 768 pixels is necessary to ensure clear visibility of the interface.

Meeting these requirements guarantees that users can take full advantage of the advanced features of the software, ensuring effective diagnostics and overall performance.

Advanced Functionality for Diesel Engines

The Diesel Diagnostic Link (DDDL) 8.17 offers advanced functionality that enhances diagnostics and performance management for diesel engines. These features are critical in ensuring that engines operate efficiently and meet regulatory standards.

Regeneration of DPF

One of the essential functions provided by DDDL 8.17 is the ability to perform Diesel Particulate Filter (DPF) regeneration. This process is crucial for maintaining optimal engine performance and meeting emissions regulations. DPF regeneration can occur in two primary modes: passive and active.

- Passive Regeneration: This occurs naturally when the engine reaches a specific temperature, allowing soot to combust without additional input.

- Active Regeneration: This mode requires manual intervention, where extra fuel is injected to raise the temperature of the exhaust and burn off accumulated soot.

Having the capability to initiate and monitor these regeneration processes helps in preventing filter blockage, thus extending the life of the DPF and improving overall engine efficiency.

Turbo Testing

Turbocharger performance is vital for maximizing engine power and efficiency. DDDL 8.17 provides functionality for turbo testing, which allows users to assess the operational status of the turbo system.

- Performance Monitoring: The software can check for issues such as under-boost or over-boost conditions, ensuring that the turbocharger is functioning within its specified parameters.

- Parameter Adjustment: It enables technicians to adjust turbo parameters for enhanced performance, depending on the engine’s operational needs.

This capability is essential for diagnosing potential turbo-related issues before they escalate, ultimately leading to costly repairs and downtime.

Comprehensive Engine Evaluation

DDDL 8.17 allows for comprehensive engine evaluation, providing insights into various aspects of engine performance. This evaluation includes:

- Parameter Assessment: Technicians can analyze real-time performance metrics, including fuel efficiency, exhaust temperatures, and EGR operation.

- System Integrations: The tool evaluates how well the engine systems integrate with each other, helping to identify any discrepancies that could impact performance.

The comprehensive engine evaluation feature enables a thorough understanding of engine health, facilitating timely maintenance and proactive repairs.

Importance in the Diesel Environment

Understanding the significance of advanced diagnostic tools within the diesel sector is essential for maintaining performance and compliance. These tools are vital in navigating increasingly strict environmental regulations and enhancing engine efficiency.

Compliance with Environmental Regulations

As environmental concerns rise, regulations governing emissions from diesel engines have become more stringent. Compliance with these regulations is necessary not only to avoid legal repercussions but also to promote sustainable practices in the industry. Key aspects include:

- Regular monitoring of emissions to ensure they are within permissible limits.

- Quick diagnostic capabilities to identify potential emissions-related issues before they escalate.

- Support for system updates that align with changing regulatory standards.

By utilizing effective diagnostic tools, fleet operators can achieve compliance more efficiently, minimizing downtime and fostering a commitment to environmental responsibility.

Enhancing Engine Performance

Improving the performance of diesel engines is crucial for operational efficiency and cost-effectiveness. Enhanced diagnostics play a pivotal role in this process. Important factors include:

- Identifying Inefficiencies: Advanced diagnostic capabilities help in pinpointing issues that may hinder engine performance, such as fuel delivery problems or air intake restrictions.

- Optimizing Maintenance: Utilizing real-time data from diagnostics allows for scheduled maintenance based on actual engine conditions rather than arbitrary timelines, reducing wear and tear.

- Boosting Fuel Economy: Comprehensive evaluations improve fuel efficiency, which not only lowers operational costs but also decreases environmental impact.

The use of sophisticated tools enables technicians to make informed decisions, ultimately contributing to improved engine longevity and operational savings.

Access and Licensing

Access and licensing for the Diesel Diagnostic Link DDDL 8.17 are straightforward, ensuring that users can obtain and utilize the software efficiently. This section outlines how to acquire the software and the associated costs.

How to Acquire

Acquiring the DDDL 8.17 is a simple process that includes various options to suit different user needs. The software can be accessed through authorized distributors or directly through the official website of Detroit Diesel. Interested buyers can follow these steps:

- Visit the official website or an authorized distributor’s site.

- Select the DDDL 8.17 software from the product offerings.

- Follow the prompts for installation and payment.

- Once the purchase is completed, users will receive a license key via email or through their account on the distributor’s platform.

Cost and License Details

The DDDL 8.17 comes with a nominal licensing fee. This cost reflects the comprehensive functionalities embedded in the software, making it a valuable investment for businesses in the diesel engine sector. Specific details include:

- The standard license for the DDDL 8.17 is priced at $85, which unlocks all features for the user.

- This licensing fee is a one-time payment and does not require annual renewals.

- Upgrades to future versions may be available at a discounted rate for existing users, fostering long-term engagement with the software.

The licensing terms are designed to be user-friendly, enabling technicians and fleet managers to utilize the software without hidden costs or frequent renewals. This straightforward approach supports effective engine diagnostics and maintenance, ultimately promoting better operational performance.

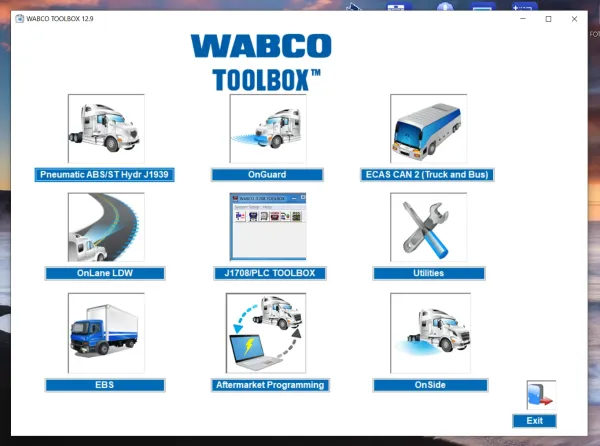

Comparison with Other Diagnostic Tools

The market for diagnostic tools is diverse, and the differences between them can significantly impact the efficiency and effectiveness of engine diagnostics. This section delves into how DDDL 8.17 stands out in a crowded field.

Specialization in Detroit and Freightliner

DDDL 8.17 is uniquely designed to cater specifically to Detroit Diesel and Freightliner engines. This specialization allows it to access comprehensive data and diagnostics that generic tools may overlook. This targeted approach provides several advantages:

- Enhanced Accuracy: The tool is intricately tuned to read and interpret data specific to these engine types, ensuring precise diagnostics.

- Tailored Features: Functions like programming and reprogramming capabilities are developed with the intricacies of Detroit Diesel engines in mind.

- Brand-Specific Updates: Regular updates are released to align with the latest engine models and technology advancements from Detroit Diesel and Freightliner.

Advantages Over Competitors

Comparative analyses often reveal that DDDL 8.17 has several key advantages when set against other diagnostic tools. These benefits contribute to its reputation as a preferred choice among diesel technicians.

- Comprehensive Functionality: Unlike some competitors that focus solely on basic diagnostics, DDDL 8.17 offers functionalities such as regeneration of DPF, turbo testing, and in-depth system evaluations.

- Cost-Effectiveness: Users have reported significant savings on repairs and maintenance that would otherwise require expensive professional services.

- User Experience: The interface is designed for ease of use, facilitating quick navigation and effective use even in high-pressure environments.

- Support and Community: As a well-established tool in the industry, DDDL benefits from widespread user experiences and shared knowledge, enhancing troubleshooting capabilities.

Customer Reviews and Feedback

Feedback from users highlights the effectiveness and reliability of this diagnostic tool in various real-world applications.

User Experiences

Users consistently report positive experiences with the software, appreciating its intuitive interface and comprehensive functionalities. Many technicians have noted that the tool significantly enhances their diagnostic capabilities and improves workflow efficiency. For example, some users highlighting the ease of navigating through different modules and accessing critical data related to engine performance. This allows for quicker identification of issues, saving valuable time in the repair process.

Real-World Applications

In practical scenarios, technicians have shared instances where the DDDL 8.17 enabled them to resolve complex problems that would have otherwise required extensive troubleshooting. Users commend the software’s ability to display diagnostic fault codes accurately, which aids in streamlining repairs and reduces downtime for fleets.

Reported Benefits

The advantages reported by users extend beyond just functionality. Many have noted significant cost savings achieved through effective diagnostics, ultimately resulting in fewer trips to dealerships or specialized service centers. The reprogramming capabilities are frequently mentioned as a standout feature that adds to the software’s versatility.

- Enhanced diagnostics and troubleshooting capabilities

- User-friendly interface for quick learning and adaptation

- Comprehensive support for various diesel engine systems

- Improves compliance with emission standards through accurate monitoring

- Cost-effective solution for maintenance and repairs

Overall, feedback indicates that the DDDL 8.17 is more than just a diagnostic tool; it serves as a valuable asset in maximizing engine performance while ensuring adherence to environmental regulations. The positive reviews emphasize its importance in the daily operations of diesel mechanics and fleet managers alike.

Future Developments and Innovations

The landscape of diesel diagnostics is evolving rapidly. New technologies are being integrated into diagnostic tools, paving the way for more efficient and accurate vehicle maintenance solutions.

Predictive Diagnostics

Predictive diagnostics is emerging as a groundbreaking trend in the field of engine management. This approach utilizes data analytics to forecast potential issues before they manifest into significant failures. By analyzing historical performance data, the software can identify patterns and anomalies that signal impending problems. Key benefits include:

- Proactive maintenance scheduling, reducing downtime.

- Cost savings by preventing major repairs.

- Enhanced engine longevity through timely interventions.

This forward-thinking capability not only streamlines repair processes but also aligns with the growing focus on sustainability in the automotive industry. Maintenance teams equipped with predictive diagnostics can deliver more informed, data-driven solutions, ensuring optimal engine performance.

CLAAS

CLAAS CNH

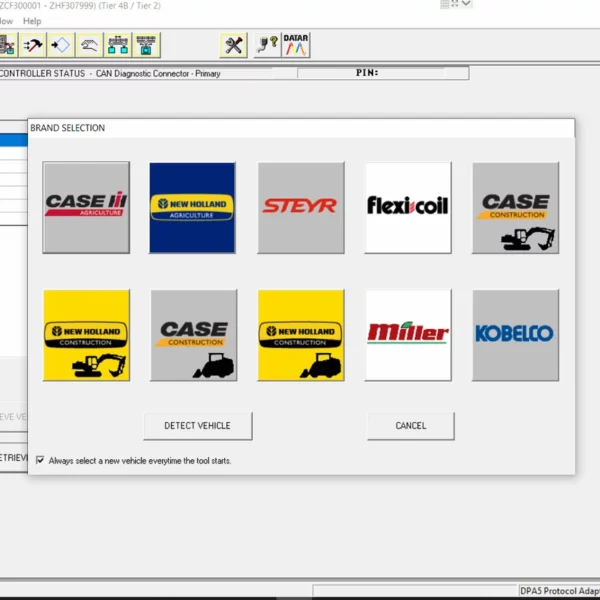

CNH

HITACHI

HITACHI

JPRO

JPRO KUBOTA

KUBOTA MAGIC TUNER

MAGIC TUNER

MANITOU

MANITOU

NEXIQ

NEXIQ NONSELF

NONSELF PACCAR

PACCAR

PSI POWERLINK

PSI POWERLINK

ZF TESTMAN

ZF TESTMAN

Reviews

Clear filtersThere are no reviews yet.