DOOSAN DIAGNOSTIC TOOL G2 STAGE V INCL T4F: Essential Software for Heavy Equipment Maintenance

The Doosan Diagnostic Tool G2 Stage V (including T4F) is an essential software solution for diagnosing and maintaining heavy equipment. It is designed to support compliance with stringent emissions regulations while optimizing engine performance. This tool offers a range of features, including compatibility with Windows 11 and support for multiple languages. Its robust diagnostic capabilities make it a valuable resource for technicians and mechanics across various industries.

Features of Doosan Diagnostic Tool G2 Stage V

The Doosan Diagnostic Tool G2 Stage V offers a variety of features designed to enhance the diagnostic and maintenance processes for heavy machinery. Its advanced capabilities ensure optimal performance and compliance with stringent emission standards.

System Compatibility

Operating System: Windows 11 (64-bit)

The software is specifically developed to operate seamlessly on Windows 11 (64-bit). This ensures that users can leverage the latest advancements in operating system technology while working with diagnostic tools. The compatibility with Windows 11 provides an intuitive interface, enhanced security features, and improved overall performance for the software. Technicians can rely on a stable environment that supports efficient diagnostics and repairs.

Database Languages: English and Korean

To cater to a global audience, the Doosan Diagnostic Tool G2 Stage V supports multiple languages, particularly English and Korean. This multilingual support enhances accessibility for technicians and users from diverse regions, streamlining communication and reducing barriers during the diagnostic process. The ability to switch languages is beneficial in multilingual workplaces or when collaborating with international teams.

Functionality

Diagnostic Capabilities

This tool boasts comprehensive diagnostic capabilities tailored for a wide range of Doosan equipment. It facilitates real-time diagnostics, allowing technicians to quickly identify issues within engines and machinery. With advanced algorithms, the software analyzes data from various engine sensors, enhancing precision in troubleshooting. An effective diagnostic tool saves time and reduces downtime in operations.

Calibration Options

The Doosan Diagnostic Tool G2 Stage V includes robust calibration options that ensure engines are performing optimally. The calibration processes adjust the parameters of the engine based on the specific needs of the machinery to meet performance and efficiency standards. This functionality plays a crucial role in maintaining compliance with environmental regulations and improving fuel efficiency.

Maintenance Support

This software provides essential maintenance support, equipping users with the necessary tools and information for regular upkeep. Routine maintenance is critical for prolonging the lifespan of heavy machinery and avoiding costly repairs. The tool assists in scheduling maintenance tasks and provides reminders, ensuring that machinery remains in peak operating condition.

Testing and Repairs

In addition to diagnostics, the Doosan Diagnostic Tool G2 Stage V offers features for testing and repair processes. Technicians can perform various tests to evaluate the functionality of different components within the machinery. This includes testing electrical systems, hydraulic functionalities, and transmission operations. The ability to execute repairs directly within the software simplifies workflows and streamlines the repair process.

License and File Size

License Time: Unlimited

The licensing for the Doosan Diagnostic Tool G2 Stage V provides an unlimited time frame for use. This aspect is particularly advantageous for businesses, as it eliminates the need for constant renewals or additional costs associated with licensing, allowing for uninterrupted access to essential diagnostic features.

Installation File Size

The installation file size for the software is contained at 152 MB, requiring 1.2 GB of space upon installation. This relatively compact size ensures that the tool can be quickly downloaded and installed on systems, making it convenient for users to get started without extensive delays. Its efficient design means that it can operate on common hardware setups without demanding excessive resources.

Compatible Engines and Equipment

Understanding the compatibility of the Doosan Diagnostic Tool G2 Stage V with various engines and equipment is crucial for effective operations across multiple sectors. This section outlines the different types of machinery that can benefit from this diagnostic tool.

Heavy Equipment Doosan

The Doosan Diagnostic Tool G2 Stage V is specifically designed to work seamlessly with a range of heavy equipment produced by Doosan. This compatibility ensures that heavy machinery can be diagnosed efficiently, optimizing performance and minimizing downtime.

Construction Machinery

In the construction sector, the tool has proven indispensable. It is tailored to diagnose and maintain the following machinery:

-

Case Construction

Case construction equipment is widely utilized in various projects, and the diagnostic tool supports its engines for effective maintenance.

-

Holland Construction

This equipment often operates under challenging conditions, making precise diagnostics essential for reliable operation and longevity.

-

JCB ServiceMaster

Naval and construction machinery from JCB can benefit from enhanced diagnostic capabilities using the Doosan tool, ensuring optimal functionality.

-

New Holland

The integration of this tool with New Holland equipment offers users the ability to maintain their machinery efficiently and effectively, even in demanding environments.

Agricultural Machinery

Agricultural applications are another significant area where this diagnostic tool excels, encompassing a variety of machinery:

-

Tractors

The diagnostic capabilities for tractors help ensure they run smoothly, which is vital during peak farming seasons.

-

Harvesters

For harvesters, timely diagnostics can prevent potential issues that could delay or disrupt the harvest process.

Industrial Uses

This diagnostic tool is not limited to only construction and agricultural machinery. It extends its applicability to various industrial machines as well:

-

Marine Engines

The functionality of the diagnostic tool ensures that marine engines perform optimally, complying with environmental standards and operational requirements.

-

Automotive Engines

In the automotive sector, accurate diagnostics enhance the longevity and performance of engines, minimizing the chances of serious mechanical failures.

Diagnostic Kits

For comprehensive diagnostics, several kits are compatible with the Doosan tool, enhancing its functionality:

-

UVIM Diagnostic Kit

This kit allows for detailed inspections and adjustments, ensuring a deep understanding of engine performance metrics.

-

Interfaces UVIM Diagnostic

Different interfaces within the UVIM range support extensive diagnostics, making the work of technicians more straightforward and efficient.

-

Nexiq USB Link

The Nexiq USB Link enhances connectivity and data transfer capabilities between the diagnostic tool and various machinery models, further streamlining the diagnostic process.

Updates and Support

Maintaining the optimal performance of the Doosan Diagnostic Tool G2 Stage V requires regular software updates and access to comprehensive support services. This section provides detailed information on available updates and the support infrastructure designed to assist users.

Software Updates

Frequent updates are vital to ensure that the diagnostic tool remains effective and current with the latest technology and compliance requirements. The updates may include new features, improved functionalities, and fixes for any issues that might arise.

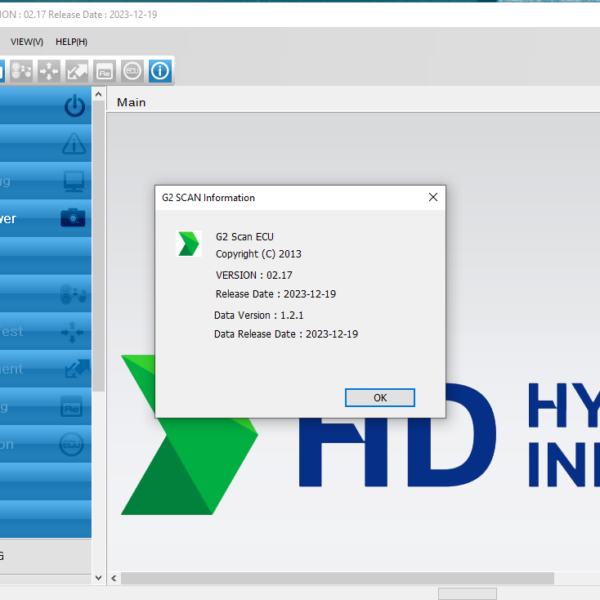

Version 01.31 [2023.06]

The latest version of the software, identified as 01.31 [2023.06], includes significant enhancements aimed at optimizing the user experience and functionality. This version introduces improved diagnostic capabilities, which facilitate quicker identification of engine and machinery issues. Technicians benefit from refined interfaces and reduced response times during diagnostics, allowing for more efficient maintenance operations.

Future Update Expectations

Looking ahead, users can anticipate additional updates that will enhance both the diagnostic and user interface experience. Future versions may focus on several key areas:

- Integration of advanced diagnostic algorithms to improve accuracy.

- Expanded compatibility with a broader range of heavy machinery models.

- Enhanced user support features to streamline troubleshooting.

- Continuous updates to ensure compliance with evolving emission standards.

The commitment to regular updates ensures that users can maintain compliance and achieve the highest level of performance in their operations.

Support Services

The availability of comprehensive support services is crucial for users of the Doosan Diagnostic Tool. Access to timely assistance can significantly reduce downtime and improve overall efficiency.

Mecaprograms Support

Mecaprograms provides dedicated support for users of the diagnostic tool. This support encompasses a variety of services, including:

- Technical assistance during installation and software usage.

- Access to detailed documentation, including manuals and troubleshooting guides.

- Regular updates to the software, ensuring seamless functionality.

These resources are designed to empower users with the knowledge and tools necessary to make the most of their diagnostic equipment.

Remote Installation via TeamViewer

For user convenience, remote installation services are available through TeamViewer. This allows support technicians to assist users directly with:

- Installation of the diagnostic software on compatible devices.

- Real-time troubleshooting to resolve any issues encountered during setup.

- Guidance on utilizing all available features effectively.

The remote installation feature enhances accessibility, ensuring that users can quickly receive help when needed, thereby minimizing operational disruptions.

Industry Relevance

The relevance of the Doosan Diagnostic Tool G2 Stage V extends across various industrial sectors, particularly due to the increasing emphasis on environmental compliance and operational efficiency. Its capabilities resonate with the demands for stringent emission standards and effectiveness in diverse market applications.

Environmental Compliance

As global awareness of environmental issues continues to grow, compliance with emission regulations has become critical. The Doosan Diagnostic Tool enables operators to adhere to these stringent standards.

Stage V Emission Standards

The Stage V emission standards represent a significant advancement in regulating the emissions produced by diesel engines. Enforced by the European Union, these standards limit harmful pollutants, necessitating the implementation of advanced diagnostics to monitor and manage emissions effectively. The tool aids in diagnosing any potential issues that may arise, ensuring that equipment remains compliant.

T4F Regulations

Similar to Stage V, the T4F regulations set forth more stringent emission controls. These regulations aim to reduce emissions of particulate matter and nitrogen oxides by requiring more effective emission control technologies. The Doosan Diagnostic Tool supports compliance with these regulations by offering precise diagnostics and maintenance solutions, helping organizations maintain operational integrity and meet legal obligations.

Market Application

The versatility of the Doosan Diagnostic Tool G2 Stage V makes it beneficial across multiple market sectors, reinforcing its importance in today’s industrial landscape. Its applications range from construction to agriculture and beyond.

Construction Industry

In the construction sector, heavy machinery plays a pivotal role. Equipment such as excavators and loaders are essential for project completion. The tool assists in identifying maintenance needs and optimizing performance, thus preventing downtime and enhancing productivity. Given the demanding nature of construction work, its diagnostic capabilities ensure that machinery operates within regulatory standards.

Agricultural Sector

The agricultural sector increasingly relies on diesel-powered tractors and harvesters. The diagnostic tool facilitates routine maintenance and troubleshooting, which can lead to improved efficiency in farming operations. This not only enhances productivity but also supports compliance with environmental regulations, which are becoming more prevalent in agri-business.

Marine and Automotive Sectors

Within the marine and automotive sectors, the necessity for reliable diagnostics cannot be overstated. Engines used in boats and vehicles are subject to strict regulations, particularly concerning emissions. The tool’s ability to conduct thorough diagnostics ensures that these engines remain compliant with current regulations while maximizing their operational efficiency. In an industry where performance and environmental impact are constantly under scrutiny, this tool becomes an invaluable resource for maintenance professionals.

User Experience

User experience plays a crucial role in the efficiency and effectiveness of diagnostic tools. Gathering insights from users helps in refining the interface and functionalities, ultimately leading to improved satisfaction and usability.

Ease of Use

The Doosan Diagnostic Tool G2 Stage V is designed with user-friendliness in mind. Technicians can navigate the interface smoothly, facilitating quicker access to functionalities needed for effective troubleshooting.

User Interface Improvements

Recent updates have emphasized the importance of a streamlined and intuitive user interface. Significant enhancements in navigation and layout have made it easier for users to find the tools and resources they require without unnecessary confusion. Responsive design features ensure that the software adapts well to various screen sizes, which is beneficial when used on different devices.

Documentation and Manuals

Comprehensive documentation is an essential component of the user experience. The availability of detailed manuals and instructional materials helps users familiarize themselves with the software’s capabilities and functions. These resources often include step-by-step guides and troubleshooting tips, which can dramatically reduce the learning curve for new users. Keeping documentation up to date ensures that it aligns with the latest software updates and functionalities.

Customer Feedback

User feedback is invaluable in shaping the direction of product development. Insights gained from technicians and mechanics who actively use the software can highlight what works well and identify areas needing improvement.

Pros Highlighted by Users

- Users frequently commend the software for its speed in diagnosing engine issues. Many technicians appreciate the quick turnaround time for troubleshooting, which ultimately minimizes downtime on the job.

- The ability to conduct adjustments swiftly is another feature that receives positive mentions. Technicians find that they can optimize engine performance with relative ease.

- Comprehensive compatibility with various engines and machinery further enhances the tool’s appeal. Users report feeling more confident in their diagnostic capabilities across a range of applications.

Areas for Improvement

- Some users have pointed out that while the interface is generally user-friendly, there are instances where additional features could be better integrated. Suggestions have been made regarding enhancing certain functionalities to support specific diagnostic needs.

- There is feedback regarding the desire for more advanced training resources. Many users believe that interactive tutorials or webinars could aid in mastering the software more effectively.

Knowledge Requirements for Effective Use

While the Doosan Diagnostic Tool G2 Stage V is accessible, users have noted that prior knowledge of engine systems can significantly enhance the software’s effectiveness. Technicians familiar with diesel engine operations tend to make better use of the advanced diagnostic features. Thus, ongoing training and continuous education in engine technologies are recommended to maximize the benefits of the software.

Future Trends

The future of diagnostic tools is rapidly evolving, bringing exciting advancements that aim to improve efficiency, accuracy, and user experience. Emerging technologies such as the Internet of Things (IoT) and artificial intelligence (AI) are set to revolutionize how heavy equipment diagnostics are approached.

Integration with IoT

The integration of IoT technology into diagnostic tools will enhance real-time monitoring and reporting capabilities. This connectivity allows for seamless communication between machinery and diagnostic systems, leading to proactive maintenance strategies.

- Real-time Data Collection: IoT devices can gather operational data, providing insights into engine performance and health.

- Remote Diagnostics: Technicians can diagnose equipment issues remotely, reducing downtime and improving response times.

- Predictive Maintenance: By analyzing data trends, businesses can anticipate potential failures and schedule maintenance before problems arise.

Predictive Analytics with AI

Incorporating predictive analytics powered by artificial intelligence represents a significant leap forward for diagnostic software. This innovation enables the software to learn from historical data and identify patterns associated with equipment failures.

- Enhanced Predictive Capabilities: AI algorithms will analyze vast amounts of data to predict when a machine may encounter issues, allowing for more strategic maintenance planning.

- Automated Problem Diagnosis: With advanced algorithms, the software can automatically identify issues and suggest solutions, streamlining the repair process.

- Improved Performance Optimization: AI-driven insights will help technicians fine-tune engines for optimal performance, increasing efficiency and reducing fuel consumption.

User Experience Enhancements

Continual improvements in user experience will play a crucial role in the adoption of diagnostic tools. Future updates will likely focus on making the software more intuitive and user-friendly.

- Streamlined Interfaces: Future versions are expected to feature enhanced user interfaces that simplify navigation and make important functions more accessible.

- Comprehensive Documentation: Improved user manuals and documentation will provide better guidance for technicians, helping them make the most of the tool’s features.

- Customizable Dashboards: Users will benefit from the ability to customize their dashboards according to individual preferences and needs, optimizing their workflow.

AGCO

AGCO ALLISON

ALLISON BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CAT

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT DOOSAN

DOOSAN EATON

EATON FREIGHTLINER

FREIGHTLINER HINO

HINO HITACHI

HITACHI HYSTER

HYSTER ISUZU

ISUZU JCB

JCB JOHN DEERE

JOHN DEERE JPRO

JPRO KUBOTA

KUBOTA MAGIC TUNER

MAGIC TUNER MAN

MAN MANITOU

MANITOU NAVISTAR

NAVISTAR NEXIQ

NEXIQ NONSELF

NONSELF PACCAR

PACCAR PALFINGER

PALFINGER PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA TAKEUCHI

TAKEUCHI THERMO KING

THERMO KING UD NISSAN

UD NISSAN VOLVO

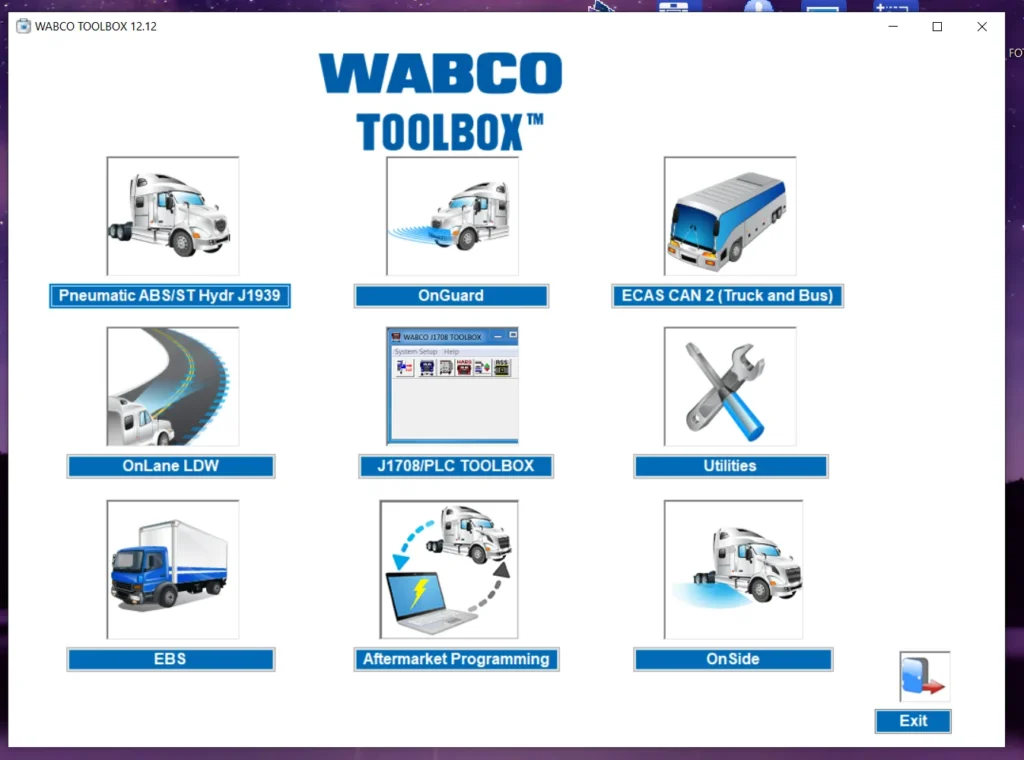

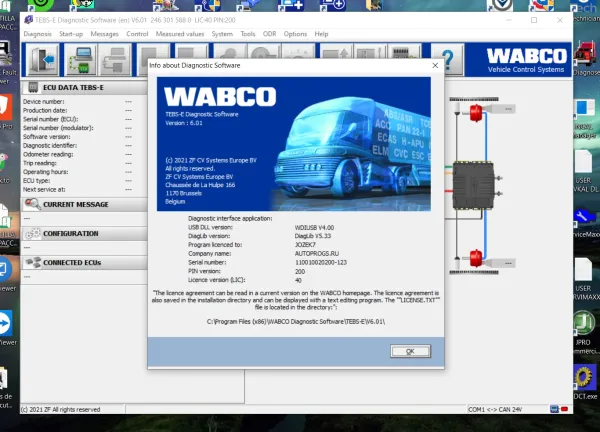

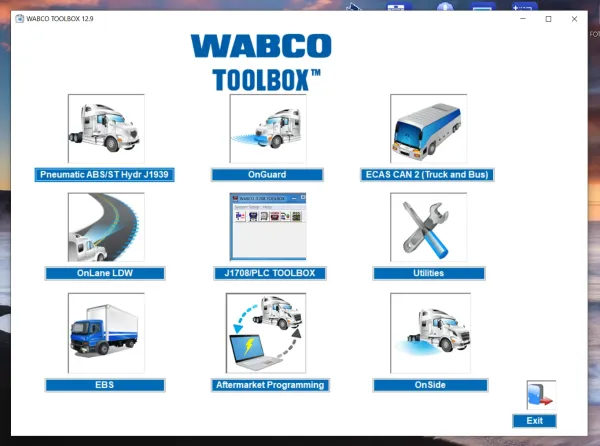

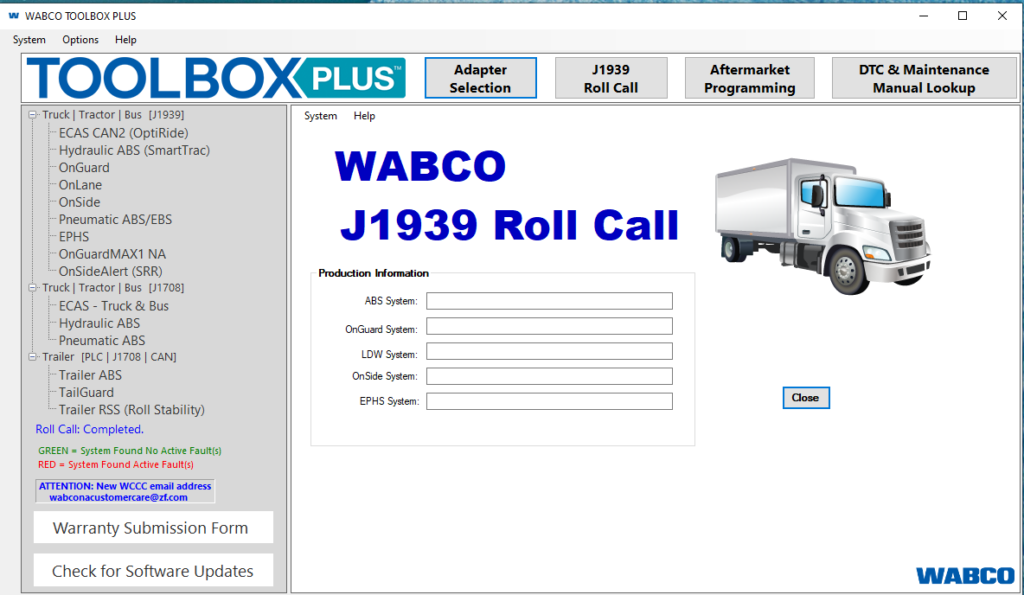

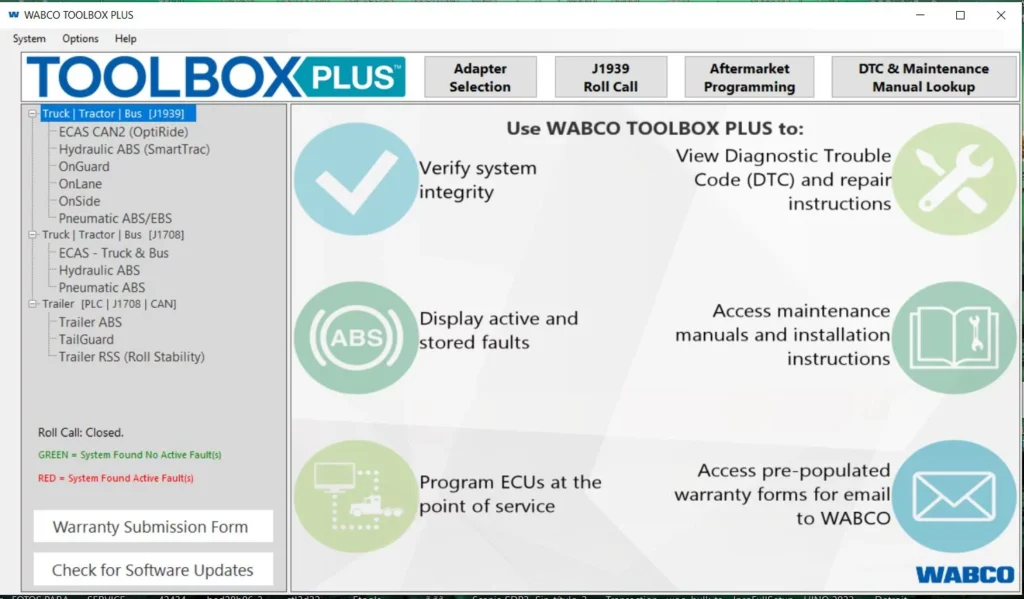

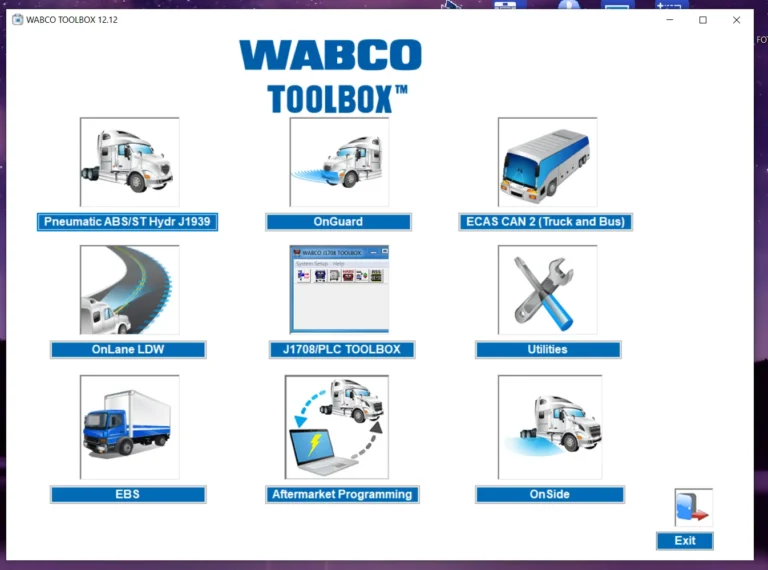

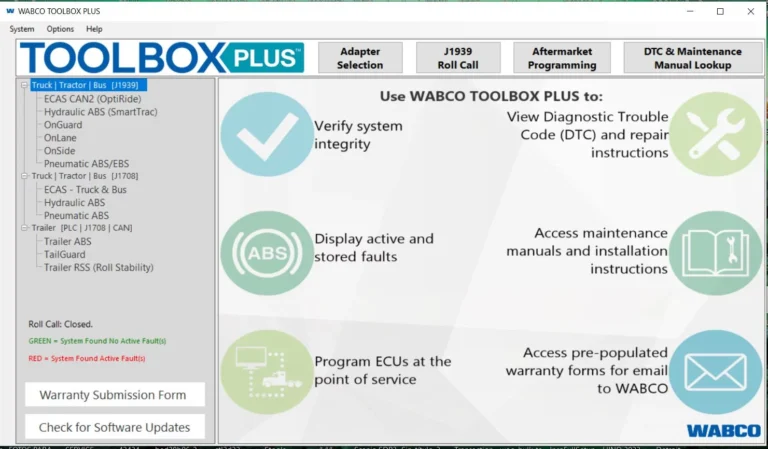

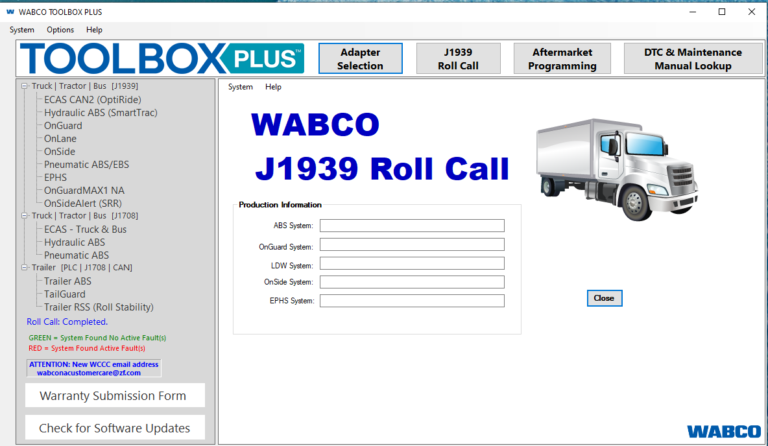

VOLVO WABCO

WABCO YALE

YALE ZF TESTMAN

ZF TESTMAN

Reviews

Clear filtersThere are no reviews yet.