Caterpillar CAT ET 2019C: Essential Diagnostic Tool for Heavy Machinery

Caterpillar CAT ET 2019C is a diagnostic tool designed for heavy machinery maintenance. It enables technicians to efficiently identify issues, adjust configurations, and enhance equipment performance. This software offers various functionalities, including error code reading and system parameter modifications. Its compatibility with multiple operating systems makes it essential for operators working with Caterpillar equipment.

Table of Contents

ToggleUnderstanding Caterpillar CAT ET 2019C

This section explores the relevance and main components of the Caterpillar CAT ET 2019C diagnostic tool. With advanced functionalities tailored for heavy machinery, it plays a pivotal role in maintaining the effectiveness of Caterpillar equipment.

Purpose and Importance

The Caterpillar CAT ET 2019C is designed to serve as a comprehensive diagnostic solution for heavy machinery. Its primary purpose is to enhance operational efficiency by enabling technicians to swiftly identify issues within the equipment.

This tool significantly reduces downtime, ensuring productivity levels are maintained. Beyond simple diagnostics, it facilitates preventative maintenance strategies, allowing for a proactive approach that enhances machinery longevity and performance.

Key Features

- Comprehensive Diagnostics: The software allows technicians to access detailed diagnostic information, making it easier to troubleshoot and fix malfunctions.

- ECM Configuration Adjustments: Users can modify parameters and settings within the Engine Control Module (ECM) to optimize machine performance.

- Error Code Reading: The tool reads and interprets error codes, providing essential insights into the machine’s operational health.

- Real-Time Monitoring: It offers capabilities for active system monitoring, giving users immediate feedback on performance metrics.

- User-Friendly Interface: The intuitive interface ensures that technicians can navigate through various features effectively, enhancing overall usability.

Functionalities of CAT ET 2019C

The CAT ET 2019C offers a comprehensive suite of functionalities designed for efficient machinery diagnostics and configurations. These capabilities enhance operational reliability and streamline maintenance procedures.

Diagnostic Tools and Capabilities

This software provides crucial diagnostic instruments that enable technicians to identify issues in heavy machinery accurately. Key diagnostic tools include:

- Reading and interpreting error codes from the ECM.

- Performing diagnostic tests to assess machine performance.

- Real-time monitoring of equipment conditions.

ECM Configurations and Adjustments

The ability to adjust ECM configurations is vital for tailoring machinery operations to specific tasks. This flexibility aids in optimizing performance and reducing wear.

Change ECM Configurations

Technicians can modify ECM settings to better align with operational requirements. This includes:

- Adjusting fuel settings to enhance engine efficiency.

- Configuring speed limits to match safety protocols.

- Tweaking power settings for various machine functions.

Parameters and Performance Data

Accessing and analyzing operational parameters is crucial for maintenance. This functionality allows users to:

- View real-time performance data for immediate assessments.

- Generate historical reports to track machine trends over time.

- Identify potential issues before they become serious, enhancing predictive maintenance strategies.

Technical Requirements

Understanding the technical requirements is crucial for ensuring smooth installation and optimal performance of the software. Below are the detailed specifications and guidelines.

System Requirements

Operating System Windows Compatibility

The CAT ET 2019C is designed to operate efficiently on various versions of the Windows operating system. The following versions are compatible:

- Windows 10

- Windows 8 and 8.1

- Windows 7

- Windows Vista

- Windows XP

Hardware Specifications

To run CAT ET 2019C effectively, the system must meet certain hardware specifications. The recommended specifications include:

- Processor: Dual-core at 2.0 GHz or faster

- RAM: Minimum of 3 GB

- Available Storage: At least 3 GB of free disk space

- Optional: DVD-ROM drive for installation

- Display: Compatible screen with a resolution of 1280×1024 or higher

- Connectivity: RS232 and USB ports for communication adapters

Installation and Setup

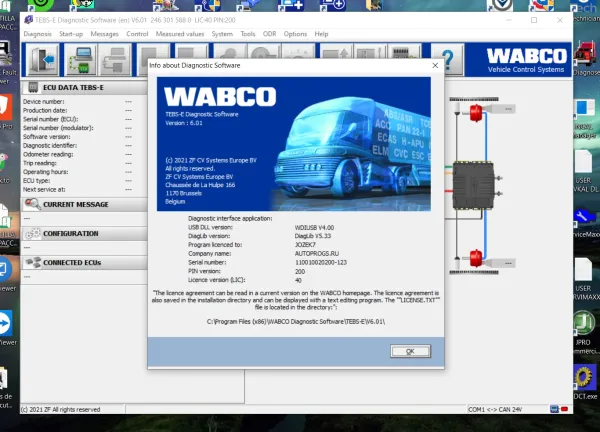

The installation process for the CAT ET 2019C software is designed to be straightforward. Users are provided with clear installation instructions to facilitate the setup. It is recommended to follow these instructions carefully to avoid any issues during the installation.

Once installed, the software may require activation. A valid license will be needed to ensure authorized use on a PC. Proper setup aids in utilizing the full capabilities of the diagnostic tool, making it essential for effective maintenance of heavy machinery.

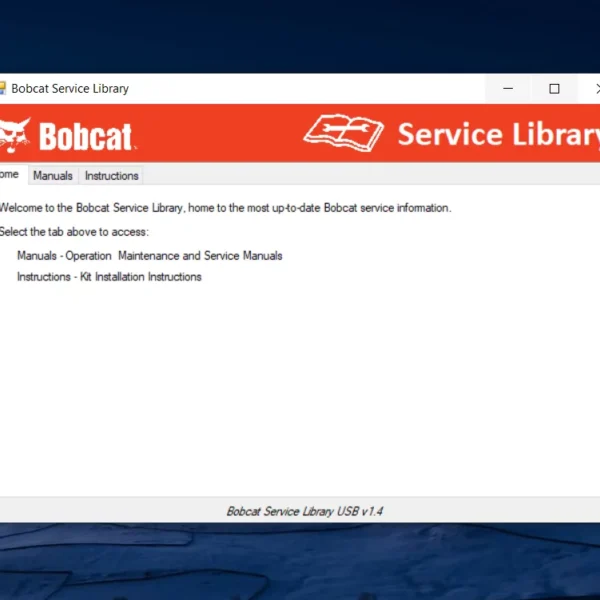

Using the Software

The process of utilizing the software involves navigating its interface and performing a variety of diagnostic tests. Understanding these functionalities enhances the effectiveness of maintenance and repairs.

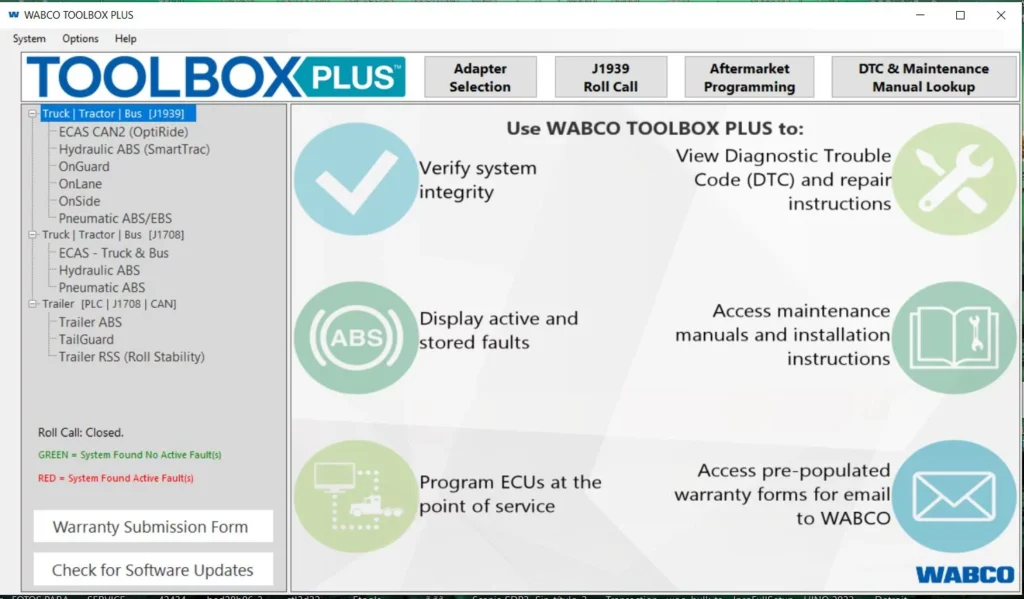

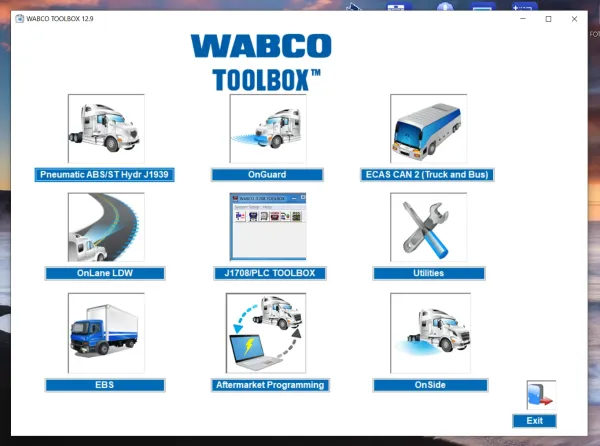

Navigating the Tool Window

The software interface is designed for usability, providing a clear view of available options. Technicians can easily access different sections, enabling efficient workflow while diagnosing issues. Key elements include menus for diagnostics, parameter adjustments, and report generation.

Performing Diagnostic Tests

Conducting diagnostic tests is fundamental for identifying equipment issues. The software offers several functionalities that streamline this process.

View Active Tests and Diagnostics

Users can view all active tests directly from the main screen. This feature allows for real-time monitoring and assessment of various system components. The diagnostics section highlights any irregularities that require immediate attention.

Print Reports and View Results

The capability to generate and print detailed diagnostic reports is crucial for record-keeping and analysis. Once the tests are complete, results can be examined in-depth. This ensures that all necessary actions can be documented, leading to improved maintenance strategies and better fleet management.

Advanced Features

The advanced features of CAT ET 2019C enhance its functionality, providing users with essential tools for effective diagnostics and management of Caterpillar machinery.

Language Support and Configuration

The software offers multi-language support, making it accessible to a diverse range of users worldwide. The available languages include:

- English

- Spanish

- German

- Italian

- French

- Chinese

- Indonesian

This flexibility allows technicians to navigate the interface and perform diagnostics in their preferred language, enhancing usability and efficiency.

Viewing Events and Status

CAT ET 2019C provides comprehensive tools for monitoring status and reviewing system events. Key components include:

The Status Area

The status area displays real-time information regarding the machinery’s operational health. Users can quickly assess:

- Current error codes

- Functional status of systems

- Alerts concerning performance irregularities

This feature aids technicians in diagnosing issues promptly, enhancing maintenance outcomes.

View Events Where Irregularities Occurred

Through event log reviews, users can pinpoint specific instances of irregularities. This includes:

- Timestamps of errors

- Types of incidents logged

- Related system parameters at the time of the event

Access to this data is vital for preventive maintenance and optimizing equipment performance over time.

Troubleshooting issues with the Caterpillar CAT ET 2019C can enhance its performance and usability. Common problems include licensing issues and challenges with adapters and communication.

Troubleshooting Common Issues

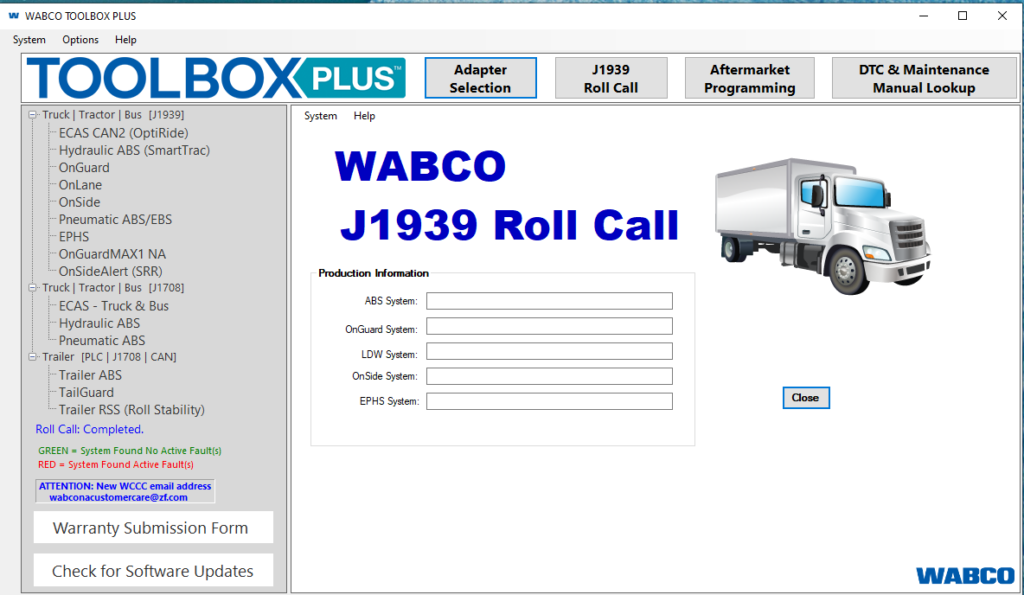

Adapter and Communication Challenges

Communication challenges can result from incompatible adapters or settings. These issues may manifest as failures to establish a connection between the software and the machinery’s Electronic Control Module (ECM).

- Confirm that the adapter is compatible with the CAT ET software version.

- Verify that the correct drivers for the adapter are installed.

- Ensure all connections are secure between the computer and equipment.

Utilizing the built-in troubleshooting guides within the software can assist in diagnosing these challenges and enhancing connectivity efficiency.

Market Availability

Understanding the market availability of Caterpillar CAT ET 2019C is crucial for users seeking this powerful diagnostic tool. It can be purchased through various reliable sources.

Where to Purchase

The Caterpillar CAT ET 2019C software is available through multiple channels, ensuring accessibility for users in different regions. Common purchasing options include:

- Authorized Caterpillar dealers

- Online marketplaces, such as Amazon or specialized heavy machinery websites

- Direct purchases from Caterpillar’s official platform

Buyers should ensure they are acquiring the software from reputable sources to avoid counterfeit products and to guarantee proper support and updates.

Regional Availability and Support

The CAT ET 2019C is designed to meet the needs of users worldwide, and its availability varies by region. Key points regarding regional support include:

- In North America, major dealers provide extensive support services.

- In Europe, authorized retailers ensure compliance with local regulations and language support.

- In Asia and the Pacific, Caterpillar’s partnerships enhance regional service availability.

Each region may offer tailored support, including installation assistance and troubleshooting, which is vital for maximizing the software’s potential.

Comparing Versions

When evaluating the advancements in diagnostic software, it is essential to consider the improvements made in each version of the Caterpillar diagnostic tool.

Improvements Over Previous Versions

The CAT ET 2019C introduces several enhancements compared to its predecessors. Key improvements include:

- Enhanced reporting capabilities that streamline the management of diagnostic data.

- Faster processing speeds, allowing technicians to conduct diagnostics more efficiently.

- Increased compatibility with the latest Caterpillar machinery models, ensuring broader application.

- A more intuitive user interface that simplifies navigation for users of all experience levels.

New Features in 2019C Version

The 2019C version brings a variety of new features that set it apart from earlier releases:

- Automated status reporting that improves product lifecycle management.

- Support for an expanded range of languages, facilitating use in diverse regions.

- New graphical tools for real-time monitoring and better data visualization.

- Integration with modern hardware for enhanced communication between the software and machinery.

CLAAS

CLAAS CNH

CNH

HITACHI

HITACHI

JPRO

JPRO KUBOTA

KUBOTA MAGIC TUNER

MAGIC TUNER

MANITOU

MANITOU

NEXIQ

NEXIQ NONSELF

NONSELF PACCAR

PACCAR

PSI POWERLINK

PSI POWERLINK

ZF TESTMAN

ZF TESTMAN

Reviews

Clear filtersThere are no reviews yet.