CLAAS MetaDiag 2016: Essential Diagnostic Software for Agricultural Machinery

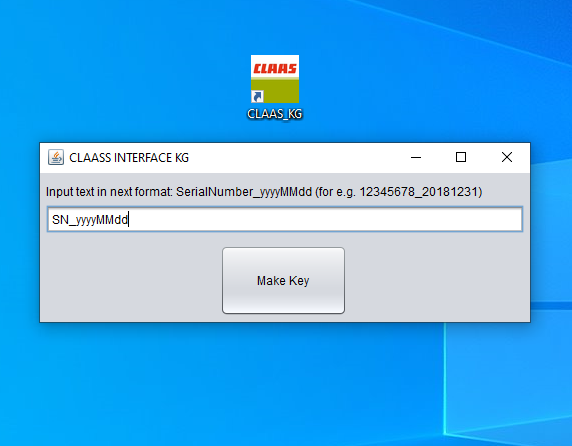

CLAAS MetaDiag 2016 is a specialized diagnostic software designed for agricultural machinery. It facilitates troubleshooting, ECU reprogramming, and software updates, making it essential for maintenance professionals. The software supports a variety of CLAAS models and is compatible with modern operating systems. Installation is straightforward and can be conducted remotely via TeamViewer, ensuring efficient setup and support.

Table of Contents

ToggleOverview of CLAAS MetaDiag 2016

This section provides insights into the key aspects of CLAAS MetaDiag 2016, focusing on its features, system requirements, and language options.

Key Features

CLAAS MetaDiag 2016 comes equipped with an array of functionalities that enhance diagnostics and maintenance for agricultural machinery. These include:

- Advanced diagnostics tools for identifying potential malfunctions.

- ECU reprogramming options to optimize machinery performance.

- Regular software updates to ensure up-to-date functionality.

System Requirements

For optimal performance, certain system specifications must be met. The following are the essential requirements:

- Operating System: Compatible with Windows 10 (64-bit) and Windows 11 (64-bit).

- Storage Space: Requires 258 MB for download and approximately 189 MB for installation.

Language Support

CLAAS MetaDiag 2016 supports multiple languages, catering to a wide range of users globally. The available languages include:

- English

- Spanish

- French

Diagnostic Capabilities

The diagnostic capabilities of CLAAS MetaDiag 2016 facilitate effective maintenance and repair of agricultural machinery. This software is equipped with advanced tools that streamline troubleshooting processes and enhance the overall efficiency of diagnostic tasks.

Troubleshooting and Error Detection

This feature allows technicians to quickly identify and analyze faults in CLAAS equipment. Utilizing real-time data, the software generates detailed error codes and descriptions, enabling prompt resolution of issues. Key aspects include:

- Access to specific diagnostic trouble codes (DTCs).

- Analysis of live data streams for deeper insights.

- Systematic fault isolation techniques.

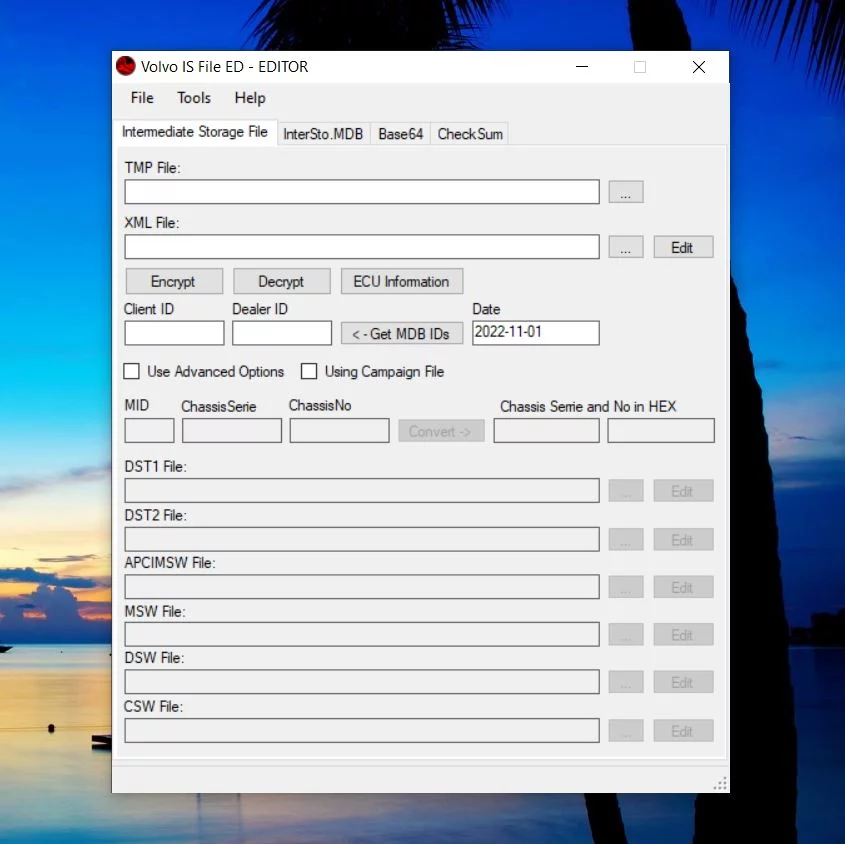

ECU Reprogramming Tools

Reprogramming the Electronic Control Unit (ECU) can optimize machinery performance. The tools provided within the software empower technicians to adjust settings and update firmware. Core functionalities include:

- Modification of ECU parameters to enhance efficiency.

- Incorporation of software updates for improved performance.

- Support for various ECU models within the CLAAS lineup.

Software Updates

Staying current with software updates is essential for maintaining optimal diagnostic performance. MetaDiag offers regular updates that ensure technicians have the latest tools and data at their disposal. Benefits consist of:

- Access to the newest diagnostic features.

- Continual improvements in software stability.

- Enhanced compatibility with new machinery models.

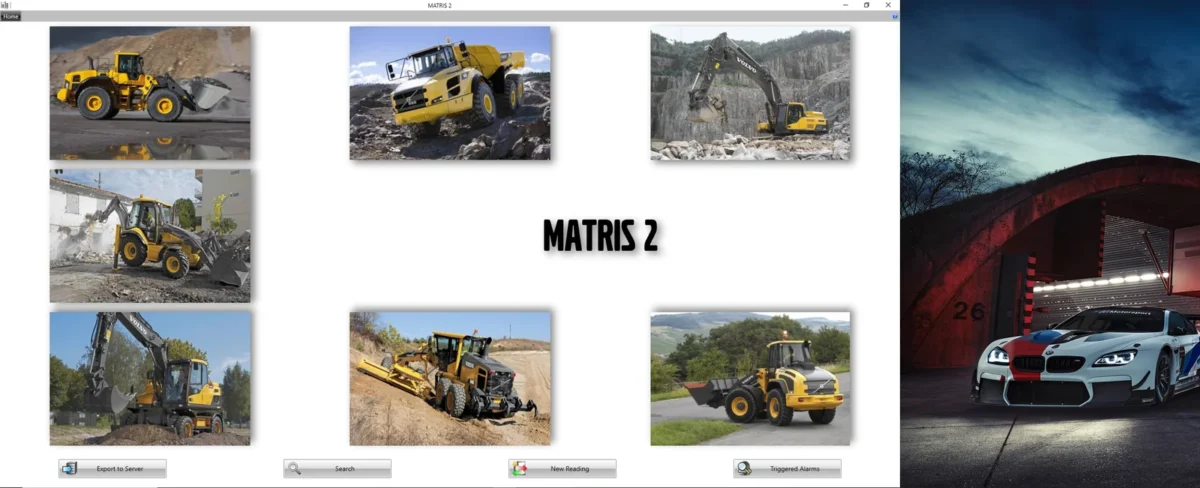

Vehicle Compatibility

Understanding the compatibility of CLAAS MetaDiag is crucial for ensuring seamless diagnosis and performance enhancement across various agricultural models. This software supports a wide range of both older and newer machinery, making it a versatile tool for technicians and operators.

ARES Models

The ARES series offers compatibility with several models that enhance its utility for users. Below are the specific models that can leverage the diagnostic tools effectively.

- ARES 5×0-6×0

- ARES 7×0

ARION Models

For the ARION series, MetaDiag provides extensive coverage, allowing technicians to tap into advanced diagnostic functionalities for these popular models.

- ARION 5×0 CEBIS

- ARION 6×0 CIS

AXION Models

Within the AXION line, various configurations are supported, ensuring that users can maintain and program their machinery with efficiency.

- AXION 8×0 Variants

Installation and Licensing

Understanding the installation process and licensing terms is essential for efficient software utilization. Each component plays a crucial role in ensuring smooth operation and accessibility.

Installation Process

The installation procedure for the software is designed to be straightforward. Users can install it on a single PC with the necessary system specifications. It simplifies the installation experience, minimizing technical hurdles.

Remote Setup via TeamViewer

For added convenience, installation support can be provided via TeamViewer. This feature allows technicians to assist users remotely, making the process more efficient and resolving issues in real-time. This approach ensures that users do not navigate technical challenges alone, facilitating a smoother transition to the software.

Licensing Terms

The software is available under a long-term licensing agreement, offering unlimited usage without additional costs. This arrangement is beneficial for users who prefer a consistent and hassle-free experience. Licensing terms are designed to provide flexibility, ensuring that customers can maximize their investment in the software across multiple uses and updates.

New and Improved Features in 2016 Version

The 2016 version of the software introduces significant enhancements that improve user interaction and overall efficiency.

User Interface Enhancements

A more intuitive user interface simplifies navigation and improves the user experience. The layout has been redesigned to allow easier access to key features and functionalities, enabling technicians to complete tasks more quickly.

Performance Improvements

Enhanced performance metrics ensure faster response times during diagnostics and ECU reprogramming. These optimizations streamline workflows, allowing users to handle multiple tasks effectively without system lag, thereby increasing productivity.

Additional Diagnostic Tests

This version includes new diagnostic tests that are tailored to identify emerging issues in machinery. The expanded range of tests contributes to a more comprehensive understanding of machine health and facilitates early problem detection.

Related Products

For those interested in enhancing their agricultural machinery diagnostics, several related products complement the capabilities of CLAAS MetaDiag 2016.

Diagnostic System Kits

These comprehensive kits offer an array of tools designed for effective troubleshooting and maintenance. Key components may include:

- Diagnostic scanners that interface with various machinery.

- Probes and sensors for real-time data collection.

- Documentation including user manuals and troubleshooting guides.

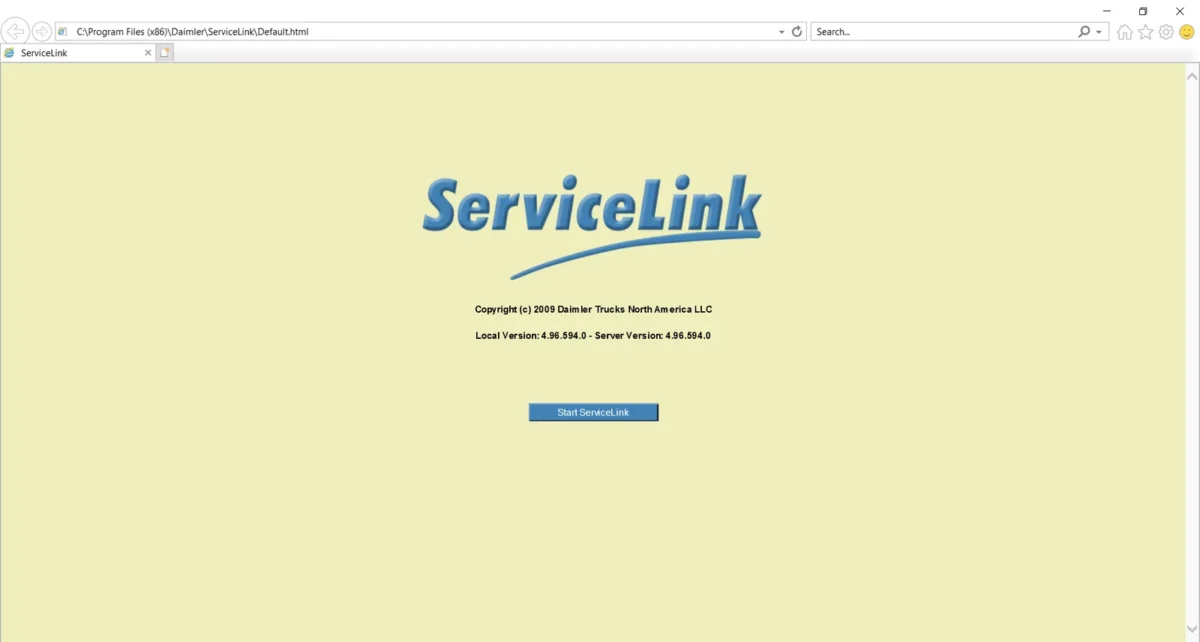

Heavy Equipment Solutions

Solutions for heavy equipment are tailored to meet the demands of various work environments. Features typically encompass:

- Advanced monitoring systems for real-time performance tracking.

- Software solutions for maintenance scheduling and reporting.

- Integration options with existing fleet management systems.

Spare Parts Software

This type of software allows users to efficiently manage and order spare parts for agricultural machinery. Important aspects include:

- A searchable database of parts compatible with numerous CLAAS models.

- Inventory tracking features to prevent equipment downtime.

- User-friendly interfaces for effortless navigation and ordering.

Purchasing Information and Support

Acquiring the necessary tools for maintaining agricultural machinery is vital. This section covers pricing aspects and available support services for optimal user experience.

Pricing Details

The cost of acquiring the software is set at USD 249. This price reflects a significant discount from its original retail price of USD 350. Customers can expect occasional special offers, allowing for potential further savings. Such pricing strategy makes it accessible for various operators and technicians looking to enhance their diagnostic capabilities.

Customer Support Services

Purchasing this software comes with a robust suite of customer support options. This ensures users can maximize their use of the product effectively. The support services available are tailored to assist both novice and experienced users.

Technical Assistance

Support extends to technical assistance for installation and troubleshooting. Users can obtain help not only during the initial setup but throughout their usage through readily available resources. This may include detailed guides and expert advice tailored to specific issues encountered.

Global Shipping Information

Global shipping is facilitated at no additional cost through DHL Express. This ensures that customers worldwide can receive their software promptly, making it an attractive option for international buyers. The shipping process is designed to be efficient, guaranteeing that technicians can access their diagnostic tools without unnecessary delays.

Frequently Asked Questions

This section provides answers to common inquiries related to CLAAS MetaDiag 2016. The following topics address compatibility, language support, and system performance to help users maximize their experience.

Compatibility Concerns

Many users question whether their machinery will work with this software. The program supports a wide range of CLAAS machinery. Compatibility is determined by the model and year of manufacture.

- ARES Models

- ARION Models

- AXION Models

Each of these series includes specific sub-models that may or may not be fully supported.

Language and Regional Use

Language support is crucial for users worldwide. The software is available in several languages, including English, Spanish, and French. This is beneficial for technicians in various regions.

- The efficiency of diagnostics may depend on the user’s familiarity with technical terms available in their preferred language.

- Regional variations can also influence the availability of support and updates.

System Performance Advice

Optimal performance is essential for effective diagnostics. Users should ensure their systems meet the minimum requirements before installation. Regular updates are also advised to maintain software efficacy.

- Monitor the software’s performance regularly to identify any potential issues.

- Utilize remote assistance features if any installation challenges arise.

CLAAS

CLAAS CNH

CNH

HITACHI

HITACHI

JPRO

JPRO KUBOTA

KUBOTA MAGIC TUNER

MAGIC TUNER

MANITOU

MANITOU

NEXIQ

NEXIQ NONSELF

NONSELF PACCAR

PACCAR

PSI POWERLINK

PSI POWERLINK

ZF TESTMAN

ZF TESTMAN