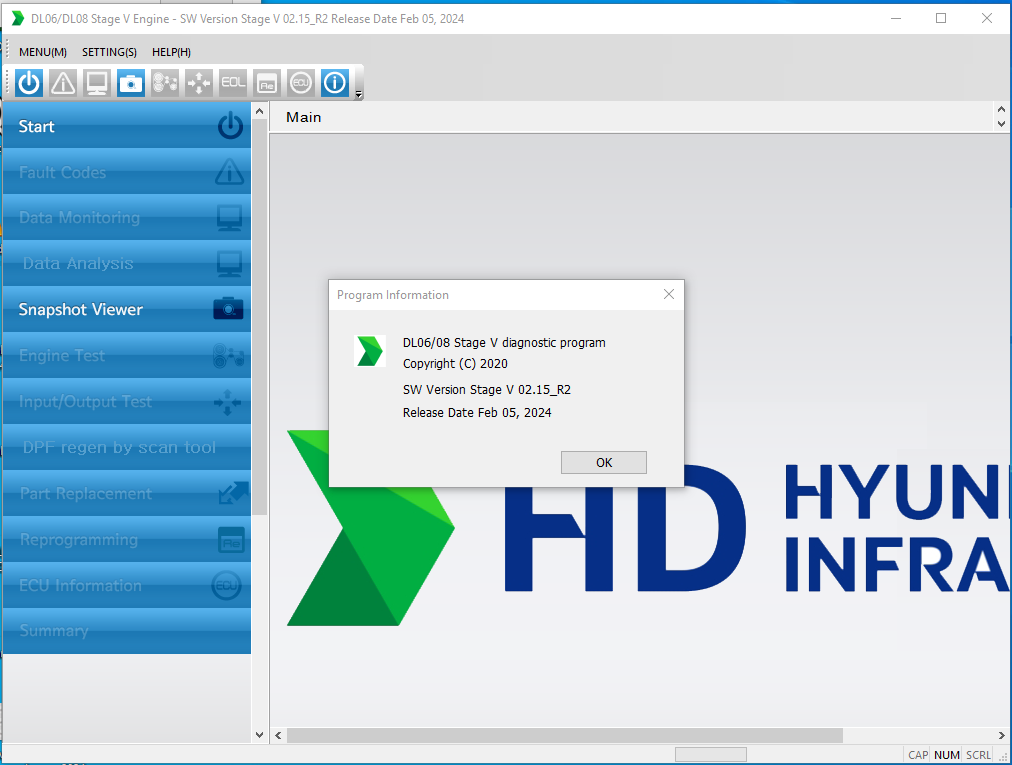

DOOSAN DIAGNOSTIC TOOL DL06 DL08 Stage V 02.15 R2 [2024.02] English Chinese: Optimize Your Heavy Machinery Today!

The Doosan Diagnostic Tool DL06 DL08 Stage V 02.15 R2 [2024.02] is an essential software solution for diagnosing heavy machinery. It offers advanced capabilities suited for the latest Doosan models with a focus on efficiency and compliance. This tool features a bilingual interface in English and Chinese, ensuring accessibility for a diverse user base. It supports real-time performance monitoring and provides detailed reporting, making it an invaluable asset for maintenance and operational efficiency.

Table of Contents

ToggleKey Attributes of the Doosan Diagnostic Tool

The Doosan Diagnostic Tool offers a range of key attributes designed to enhance the efficiency of heavy machinery diagnostics. These features make it a vital resource for operators looking to optimize their equipment performance and maintain compliance with modern standards.

Interface Languages

This tool is equipped with a bilingual interface, available in both English and Chinese. This feature facilitates ease of use across diverse operating environments, allowing users from different linguistic backgrounds to access and interpret diagnostic data effectively. The intuitive layout ensures that operators can quickly navigate the software without extensive training.

Compatibility with Doosan Models

The Doosan Diagnostic Tool is compatible with a variety of Doosan machinery models, including the latest versions in the DL06 and DL08 series. This broad compatibility ensures that users can utilize the tool across multiple pieces of equipment, making it a versatile addition to any fleet. It not only supports current models but also extends its functionality to older units, offering a comprehensive solution for maintenance.

Advanced Diagnostic Capabilities

One of the standout features of the Doosan Diagnostic Tool is its advanced diagnostic capabilities. This includes sophisticated algorithms that allow for quick and accurate fault detection.

Specific Fault Identification

With the ability to identify specific faults, the tool can analyze engine codes and operational data to pinpoint issues that may not be apparent during routine inspections. This precise fault identification helps maintenance teams to address problems before they escalate, significantly reducing downtime.

Performance Monitoring

The performance monitoring feature tracks critical engine metrics in real time, providing insights into engine health and operation. This continuous monitoring allows operators to gauge the effectiveness of their machinery throughout daily operations, ensuring optimal performance and longevity of equipment.

Software Updates

Regular software updates ensure that the Doosan Diagnostic Tool remains at the forefront of technological advancements. These updates provide users with the latest features and improvements, enhancing overall functionality and keeping the diagnostic capabilities aligned with the evolving standards of the industry. By maintaining an up-to-date system, users can mitigate risks associated with outdated diagnostics.

Data Storage and Reporting

The tool includes robust data storage capabilities, allowing for the archival of diagnostic histories and operational statistics. Users can generate comprehensive reports that summarize machine performance and maintenance activities. This reporting feature not only aids in decision-making but also serves as a crucial tool for compliance documentation, particularly regarding emission standards.

Benefits of Using the Doosan Diagnostic Tool

The Doosan Diagnostic Tool provides a range of advantages that enhance operations and reduce costs for equipment users in the construction and heavy machinery sectors.

Cost Savings in Maintenance

Utilizing the Doosan Diagnostic Tool can lead to significant cost savings in maintenance. By enabling operators to detect potential issues before they escalate into major failures, companies can avoid expensive repairs and extended downtime. This proactive approach not only helps in preserving the integrity of the machinery but also ensures that resources are allocated more efficiently.

Regular diagnostics can identify wear and tear on components, allowing for timely replacements. This reduces the likelihood of unexpected breakdowns and the associated high costs. Furthermore, with the ability to track maintenance history, operators can make informed decisions about service schedules and budgeting for future maintenance needs.

Operational Efficiency

Increased operational efficiency is another key advantage of the Doosan Diagnostic Tool. The advanced diagnostic capabilities allow for quick identification of performance issues, enabling operators to resolve problems swiftly. This quick response minimizes downtime, ensuring that machinery is up and running at optimal performance levels.

Moreover, the real-time data access feature allows operators to monitor equipment conditions continuously. Performance metrics can be analyzed to enhance productivity. Insights gained through the tool can lead to improved operational strategies and better resource management across projects.

Support and Training

The Doosan Diagnostic Tool also offers comprehensive support and training for users, which is crucial for maximizing its benefits. Access to training materials and technical support ensures that operators are well-equipped to utilize the tool effectively. This knowledge transfer is essential for fostering a culture of proactive maintenance and efficient operations.

Having a skilled workforce that understands how to use the diagnostic tool can significantly impact overall productivity. Operators can become adept at interpreting data and making timely decisions based on the readings, potentially enhancing the operational workflow.

Detailed Reporting Features

In addition, the tool’s detailed reporting features enhance decision-making capabilities for fleet managers and operators alike. The ability to generate comprehensive reports on equipment health, performance trends, and maintenance history provides valuable insights that inform operational strategies.

- Reports can be generated in various formats, such as PDF and Excel, facilitating easy sharing and analysis.

- Detailed diagnostics can highlight recurring issues, helping to pinpoint areas for improvement.

- The data collected can aid in compliance reporting, ensuring that operations align with industry regulations and standards.

By leveraging these reporting capabilities, businesses can optimize their maintenance schedules and operational procedures, leading to a more efficient and cost-effective approach to managing their fleet.

Technical Specifications

The technical specifications of the Doosan Diagnostic Tool are crucial for ensuring optimal performance and compatibility with heavy machinery. These specifications provide information on software requirements, connectivity options, storage abilities, and real-time data access features that enhance equipment management and maintenance.

Software Requirements

To effectively operate the Doosan Diagnostic Tool, specific software and hardware requirements must be met. The software is designed to run on a minimum of Windows 10, with support available for more recent versions of the operating system. This compatibility ensures that users can leverage the latest enhancements and security features provided by Microsoft.

In addition to the operating system, the following specifications are important:

- Processor: A modern multi-core processor for efficient data handling and processing.

- RAM: At least 4 GB of RAM is recommended to ensure smooth operation and multitasking capabilities.

- Graphics: A graphics card capable of supporting the necessary resolutions for optimal display, particularly for performance visualizations.

Connectivity Options

Connectivity is a vital aspect of the Doosan Diagnostic Tool, facilitating seamless integration with various devices. The tool is equipped with USB connectivity, which allows it to be easily connected to laptops and tablets. This feature ensures that users can access diagnostic data in a convenient and efficient manner.

Moreover, the tool supports various data transmission methods, including:

- USB 2.0 and USB 3.0 connections for faster data transfer rates.

- Wireless communication options, which enable remote connectivity through compatible devices.

Storage Capabilities

The storage capabilities of the Doosan Diagnostic Tool are designed to handle extensive data collection and reporting. It allows users to store diagnostic history, software logs, and performance metrics efficiently. This feature is essential for ongoing maintenance and troubleshooting.

The tool supports various storage formats, including:

- Local storage on the connected device for immediate access to data.

- Cloud storage options for backup and remote access, allowing data continuity even when devices are not physically present.

Real-Time Data Access

Real-time data access is one of the standout features of the Doosan Diagnostic Tool. This functionality enables users to monitor equipment performance and diagnose issues as they occur. Such immediate feedback is instrumental in preventing potential breakdowns and enhancing operational efficiency.

Key elements of real-time data access include:

- Live monitoring of engine performance metrics, allowing for quick adjustments and interventions.

- Instant fault reporting, which enables technicians to address issues promptly and minimize downtime.

Understanding the Variants

Different modes of the Doosan Diagnostic Tool cater to specific machinery needs. These variants enhance the diagnostic capabilities tailored for various models and operational requirements.

Mode DL06

The DL06 mode is engineered for use with Doosan excavators, providing specialized diagnostics that focus on essential functionality and performance metrics. This mode is instrumental for operating the advanced features of the DL06 model.

Focus on Excavator Models

The DL06 mode primarily targets excavator models equipped with the DL06 engine. It integrates sophisticated diagnostic capabilities that facilitate precise analysis of the hydraulic systems, engine performance, and maintenance needs.

Operators can leverage this mode to troubleshoot issues specific to excavators, ensuring optimal performance and minimal downtime. The detailed diagnostic data aids technicians in understanding machine behavior and addressing any irregularities efficiently.

Emission Control Diagnostics

In light of stringent environmental regulations, the DL06 mode includes features dedicated to emissions control diagnostics. This functionality is crucial for monitoring emissions levels and ensuring compliance with environmental standards.

The tool provides real-time data on emission-related parameters, allowing for timely intervention when emissions exceed acceptable limits. By focusing on these diagnostics, operators can enhance their equipment’s performance while adhering to legal requirements.

Mode DL08

The DL08 mode is tailored for Doosan’s heavy machinery applications, facilitating advanced diagnostics across a range of powerful models. This versatility makes it a valuable asset for operators managing demanding tasks.

Heavy Machinery Applications

Designed specifically for heavy machinery, the DL08 mode supports diagnostics across various equipment such as larger excavators and bulldozers. Its capabilities extend to monitoring hydraulic systems, engines, and other key components vital for heavy-duty operations.

Utilizing this mode allows operators to receive comprehensive feedback on machinery performance, which is essential in optimizing productivity and efficiency. Regular diagnostics can foresee potential issues, minimizing unexpected repairs and reducing operational costs.

Fuel Management and Performance

Effective fuel management is pivotal in the operation of heavy machinery. The DL08 mode provides insights into fuel consumption and engine performance, enabling operators to refine their fuel strategies.

By analyzing data related to fuel usage, the tool aids in identifying patterns that can inform more efficient practices. This information is vital for maximizing engine efficiency while reducing waste and operational expenses.

The DL08 mode ensures that operators maintain their equipment’s peak performance while managing fuel costs effectively, reinforcing the importance of strategic planning in heavy machinery operations.

Compliance with Emission Norms

Ensuring compliance with emission norms is crucial for modern machinery, particularly within the construction sector. The evolving regulations necessitate that heavy equipment meets stringent environmental standards.

Importance of Stage V Compliance

Stage V compliance represents the latest advancement in emission control, targeting reductions in pollutants from diesel engines. This regulatory framework applies to a wide range of machinery, including excavators and loaders, making adherence essential for manufacturers and operators alike.

Understanding the significance of Stage V compliance involves recognizing its impact on both environmental sustainability and operational legality. Non-compliance can lead to hefty fines, increased scrutiny from regulatory bodies, and potential bans on equipment use in certain regions.

- Promotes sustainable practices within the industry

- Reduces health hazards associated with air pollution

- Enhances the overall efficiency of engine operation

- Facilitates market access in regions with strict environmental laws

Overall, meeting Stage V standards is not merely a regulatory requirement but a commitment towards building a cleaner future.

Role of Diagnostic Tools in Compliance

Diagnostic tools play an integral role in monitoring and ensuring compliance with emission norms. By providing detailed insights into engine performance and emission levels, these tools enable operators to maintain their equipment effectively and adhere to regulatory standards.

Through advanced diagnostic capabilities, machinery operators can identify potential issues before they escalate into compliance failures. This proactive approach is vital in maintaining operational integrity while mitigating risks associated with emissions.

- Facilitates early detection of faults related to emissions control systems

- Provides real-time data for accurate performance monitoring

- Assists in generating compliance reports necessary for regulatory inspections

- Enables comparative analysis of emissions over time to ensure consistent adherence

Ultimately, utilizing sophisticated diagnostic tools not only aids in meeting current standards but also prepares operators for future regulatory changes that may arise.

CLAAS

CLAAS CNH

CNH

HITACHI

HITACHI

JPRO

JPRO KUBOTA

KUBOTA MAGIC TUNER

MAGIC TUNER

MANITOU

MANITOU

NEXIQ

NEXIQ NONSELF

NONSELF PACCAR

PACCAR

PSI POWERLINK

PSI POWERLINK

ZF TESTMAN

ZF TESTMAN

![DOOSAN DIAGNOSTIC TOOL DX22 ELECTRONIC MARINE DCU ANALYZER 01.00R2 [2024.02]](https://diagtrucks.com/wp-content/uploads/2024/11/DOOSAN-DIAGNOSTIC-TOOL-DX22-ELECTRONIC-MARINE-DCU-ANALYZER-01.00R2-2024.02-600x600.png)

Reviews

Clear filtersThere are no reviews yet.