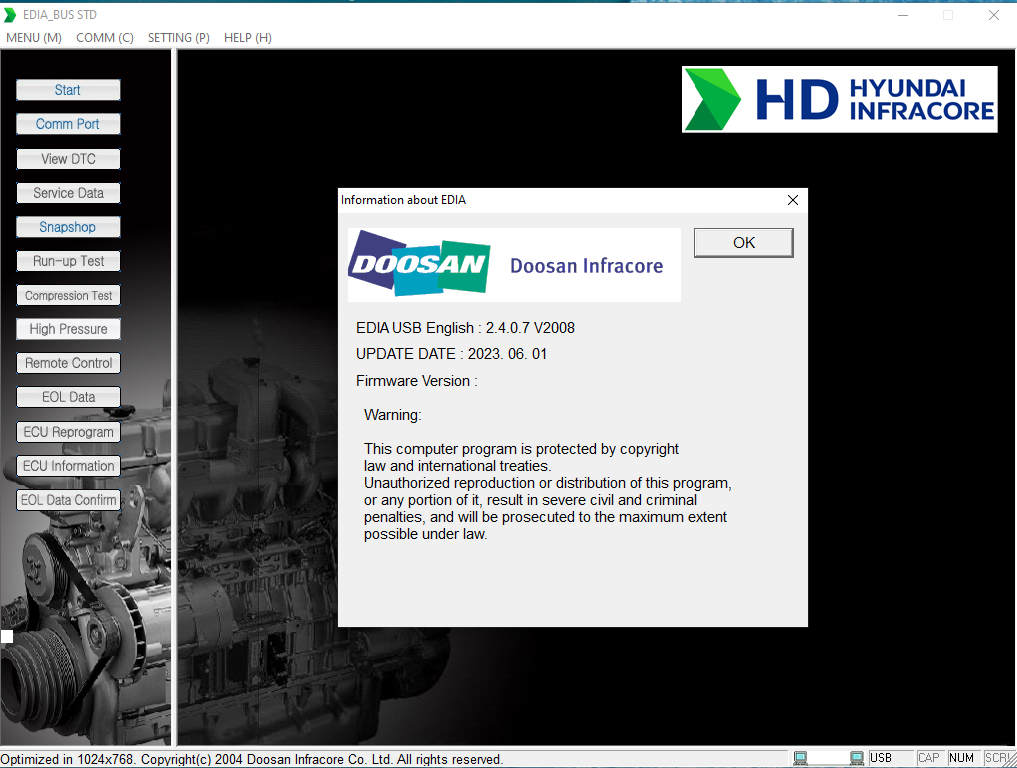

DOOSAN E POWERPACK DIAGNOSTIC PROGRAM 01.00 [2024.04] : Enhance Your Heavy Machinery Diagnostics Today!

The DOOSAN E-POWERPACK DIAGNOSTIC PROGRAM 01.00 [2024.04] is a powerful tool for diagnosing and maintaining Doosan heavy machinery. It offers robust features to optimize equipment performance and streamline maintenance processes. This software is compatible with various operating systems and supports multiple languages. The program also allows remote installation via TeamViewer, ensuring efficient setup and support for users in the field.

Table of Contents

ToggleProduct Overview

This section provides a comprehensive overview of the key features and specifications of the Doosan E-Powerpack Diagnostic Program version 01 00 2024 04. Highlighting its capabilities and requirements, it sets the stage for understanding the software’s powerful diagnostic tools.

General Features

The Doosan E-Powerpack Diagnostic Program is engineered to provide advanced diagnostic capabilities tailored to Doosan’s range of heavy machinery. This software showcases a variety of functionalities that enhance operational efficiency and maintenance accuracy. Key features include:

- Real-time diagnostics for immediate fault identification.

- Comprehensive data management for better maintenance reporting.

- Flexible installation options, including remote setup assistance.

- Compatibility with multiple diagnostic kits, maximizing versatility.

- Regular updates ensuring up-to-date information and functionality.

File Size and System Requirements

The performance and efficiency of the software are influenced by its file size and system compatibility. Understanding these requirements is crucial for optimal performance.

File Size and Space

The size of the installation file is 61.8 MB. In addition to the software installation, it requires approximately 403 MB of space upon installation to ensure it operates smoothly on the user’s system. Adequate storage space is essential for optimal performance and functionality.

Operating System Compatibility

This diagnostic program is specifically designed for 64-bit operating systems, with a focus on ensuring seamless integration with the latest versions of Windows, including Windows 11. Compatibility with a range of systems maximizes accessibility for users across various applications and setups.

Supported Languages

The software interface supports both English and Korean languages. This bilingual support caters to a diverse user base, ensuring that technicians and operators can navigate the system comfortably and effectively.

Software Licensing

The software is offered with an unlimited time license, providing users with the flexibility to utilize the program without frequent renewal. This aspect not only enhances the user experience but also underscores the value and reliability of this diagnostic tool in the maintenance of Doosan machinery.

Installation and Activation

This section provides detailed guidance on the installation and activation processes for the software. Proper installation ensures that users can efficiently utilize all the functionalities offered for optimal machinery diagnostics.

Installation Steps

The installation of the Doosan E-Powerpack Diagnostic Program is straightforward, following a series of clearly defined steps. To ensure a successful setup, users should adhere to the following instructions:

- Download the installation package from a trusted source.

- Locate the downloaded file and double-click to initiate the installation process.

- Follow the on-screen prompts to select the installation directory.

- Review and accept the license agreement to proceed.

- Complete the installation by clicking the “Finish” button when prompted.

- Restart the computer if required to finalize the installation.

Activation Methods

To enable full functionality of the software, activation must take place. There are two primary methods for activating the program, ensuring flexibility based on user preference.

Remote Installation via TeamViewer

This method provides an efficient way to install and activate the software, especially for users who may require assistance. Using TeamViewer allows a technician to remotely access the user’s computer, streamlining the installation process. The steps are as follows:

- Ensure TeamViewer is installed on the user’s system and the technician’s device.

- Initiate a session by providing the session ID and password to the technician.

- The technician will remotely guide the user through the installation process.

- Once installed, the technician will assist in the activation process, ensuring that all features are accessible.

Local Installation

For users who prefer to install and activate the software independently, local installation is a viable option. This method requires the user to manually enter the activation key received upon purchase. The local installation steps include:

- Install the software following the previously mentioned installation steps.

- Launch the program after installation is complete.

- When prompted, input the activation key accurately to unlock all software features.

- Confirm the activation by following any additional on-screen instructions.

Compatibility and Integration

The compatibility and integration of the Doosan E Powerpack Diagnostic Program extend its functionality, making it a versatile tool for technicians managing various diagnostic requirements. This section outlines the compatible diagnostic kits and supported vehicles to facilitate a seamless user experience.

Compatible Diagnostic Kits

For effective operation, the diagnostic program is designed to integrate seamlessly with specific diagnostic kits.

UVIM Diagnostic Kit

The program’s strong compatibility with the UVIM Diagnostic Kit is one of its standout features. This kit allows for enhanced diagnostics, particularly for electronic injection systems in diesel engines. Utilizing the UVIM kit, technicians can perform comprehensive scans and detailed fault analyses, maximizing the program’s capabilities.

Other Diagnostic Kits

Besides the UVIM kit, the program is also adaptable to various other diagnostic kits. This flexibility ensures that technicians have multiple options at their disposal, catering to diverse equipment and repair needs across different Doosan machinery.

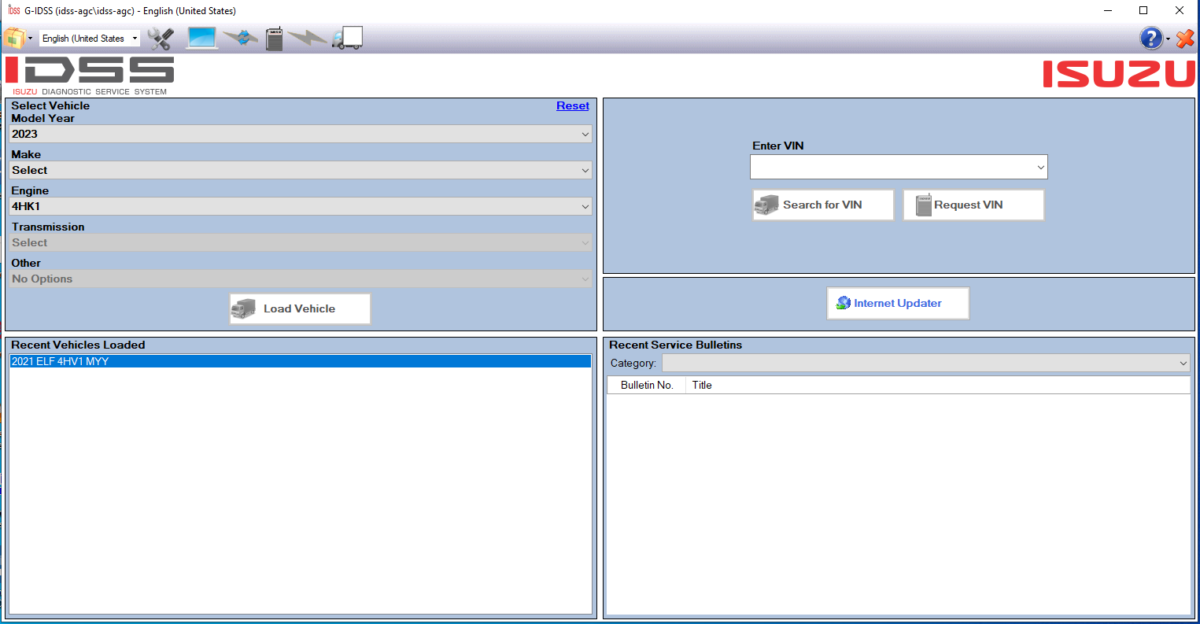

Supported Vehicles

Extensive compatibility with various vehicles makes the program an invaluable asset in the field of heavy equipment maintenance.

List of Heavy Equipment

- Excavators

- Loaders

- Dump Trucks

- Telehandlers

- Articulated Haulers

- Compact Equipment

This diverse range indicates the program’s ability to cater to a wide array of machinery, allowing technicians to handle multiple types of heavy equipment with ease.

Specific Models and Engines

The diagnostic program supports numerous specific models and engine types, enhancing its utility for maintenance teams. Some of the notable models include:

- Doosan DX Series Excavators

- Doosan DL Series Loaders

- Doosan M Series Dump Trucks

- Doosan G Series Telehandlers

By accommodating a variety of engines, technicians can ensure optimum functionality and performance across all supported Doosan vehicles. This adaptability plays a critical role in effectively diagnosing and resolving issues in real time.

Advanced Functionalities

This section outlines the advanced functionalities provided by the DOOSAN E POWERPACK DIAGNOSTIC PROGRAM 01 00 2024 04, designed to optimize diagnostic processes and enhance the user experience in heavy machinery maintenance.

Real-time Diagnostics

Real-time diagnostics are crucial for identifying issues as they occur. This functionality allows technicians to monitor machinery and detect problems promptly.

Fault Detection

The program includes sophisticated algorithms for fault detection that enable instant recognition of anomalies in machinery performance. This proactive approach assists in avoiding extensive damage by addressing issues swiftly, ensuring machinery remains operational with minimal downtime.

Real-time Error Analysis

With real-time error analysis capabilities, the software interprets fault codes as they arise. This feature not only identifies the root causes of issues but also provides actionable insights, allowing for immediate corrective actions based on data-driven analysis.

Data Management

The program’s data management functionality is designed to handle the vast amounts of diagnostic information collected during machine operation. Effective data management ensures that technicians can easily access, log, and analyze their findings.

Logging and Reporting

Comprehensive logging capabilities track all diagnostic activities, providing a detailed history of machinery performance. Customizable reporting options allow users to generate and export reports, facilitating better decision-making based on historical data and trends.

Data Storage

The software supports efficient data storage solutions, ensuring that diagnostic logs can be securely saved for future reference. This organization of data helps technicians in tracking equipment performance over time, leading to improved maintenance strategies.

System Programming and Updates

System programming and updates are vital to keep the machinery’s software in alignment with the latest technological advancements. The program offers tools to manage these updates effectively.

ECU Inspection and Updates

The ECU inspection feature allows for comprehensive evaluations of the Engine Control Unit. Regular updates ensure the ECU remains compatible with evolving standards and enhancements in engine technology, improving overall machinery efficiency and reliability.

Firmware Refresh

Firmware refresh capabilities enable the program to update not only the diagnostic software but also the firmware of connected machinery. This process is essential for optimizing performance and integrating new functionalities as they become available.

User Interface and Experience

The user interface of the Doosan E Powerpack Diagnostic Program has been designed with functionality and ease of use in mind. It prioritizes a seamless experience for technicians and mechanics interacting with heavy machinery diagnostics.

Language Options

The software supports multiple languages, allowing users to select their preferred language for a more accessible experience. This feature helps technical staff from different regions work efficiently with the program.

English Interface

The English interface offers a straightforward layout with intuitive navigation. Users can easily access functions such as real-time diagnostics, error reporting, and vehicle management. Icons and buttons are clearly labeled, allowing for quick recognition of tools and features.

Korean Interface

For users who prefer the Korean language, the program provides a fully localized interface. This ensures that all functionalities are comprehensible and easily navigable for Korean-speaking technicians, enhancing user satisfaction and productivity.

User Manual and Support

An extensive user manual accompanies the software, offering detailed instructions for installation, activation, and operational guidance. This manual is designed to assist users in maximizing the program’s capabilities efficiently.

Remote Assistance

Support for remote assistance is provided, making it possible for technicians to receive help without being physically present. This is particularly beneficial for troubleshooting issues or guiding users through specific processes via TeamViewer, ensuring that users remain productive even when challenges arise.

CLAAS

CLAAS CNH

CNH

HITACHI

HITACHI

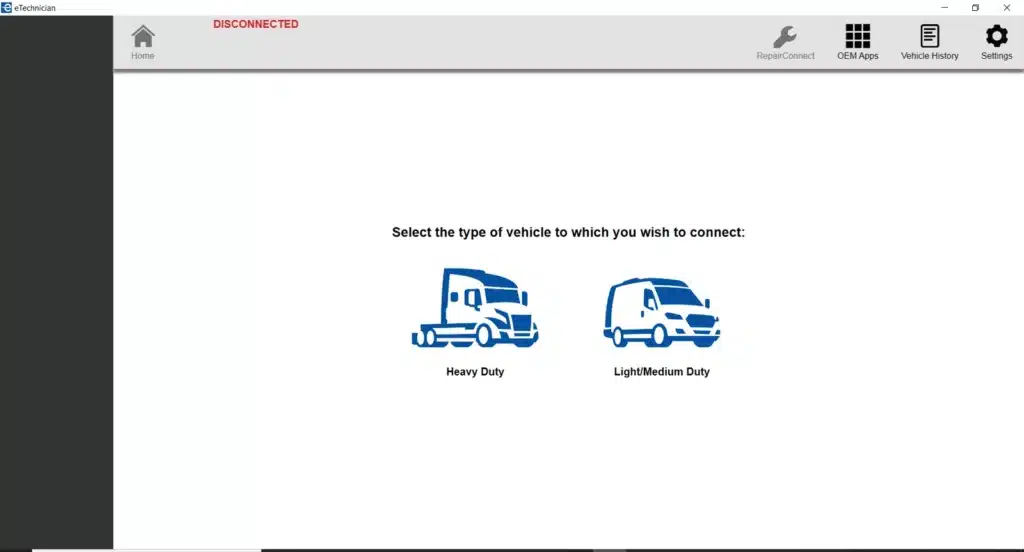

JPRO

JPRO KUBOTA

KUBOTA MAGIC TUNER

MAGIC TUNER

MANITOU

MANITOU

NEXIQ

NEXIQ NONSELF

NONSELF PACCAR

PACCAR

PSI POWERLINK

PSI POWERLINK

ZF TESTMAN

ZF TESTMAN