TRUCK SOFTWARE

CLAAS

CLAAS CNH

CNH

HITACHI

HITACHI

JPRO

JPRO KUBOTA

KUBOTA MAGIC TUNER

MAGIC TUNER

MANITOU

MANITOU

NEXIQ

NEXIQ NONSELF

NONSELF PACCAR

PACCAR

PSI POWERLINK

PSI POWERLINK

ZF TESTMAN

ZF TESTMAN

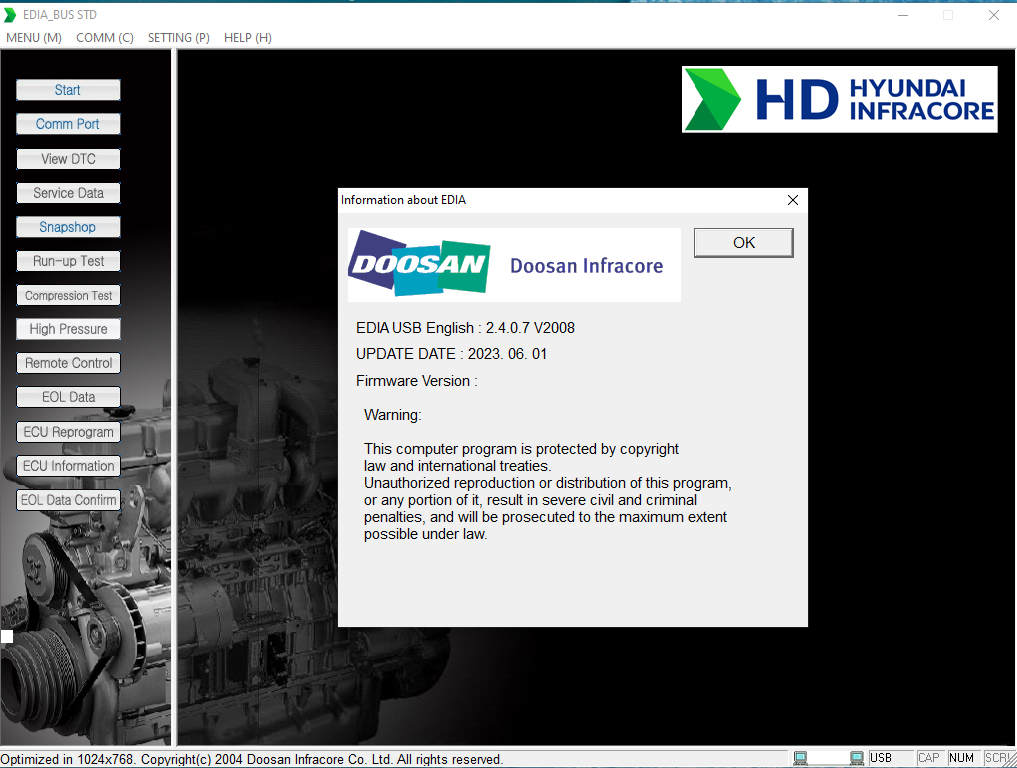

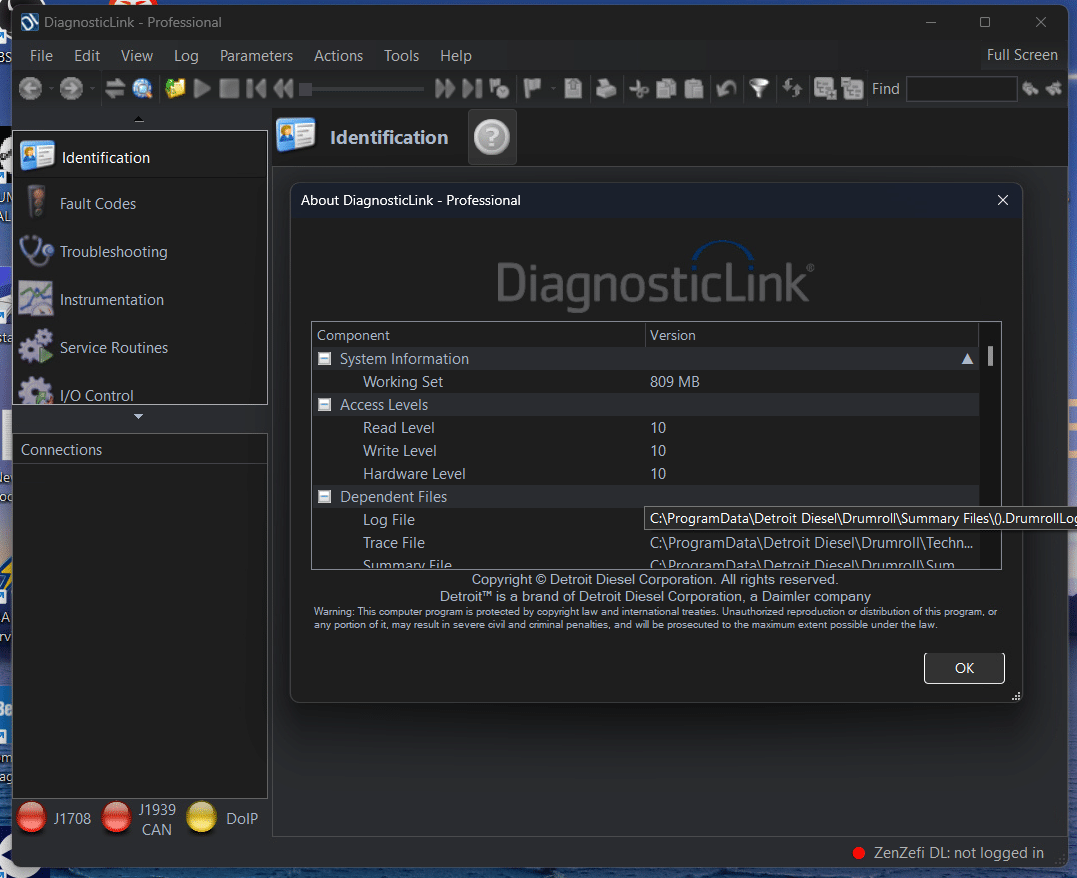

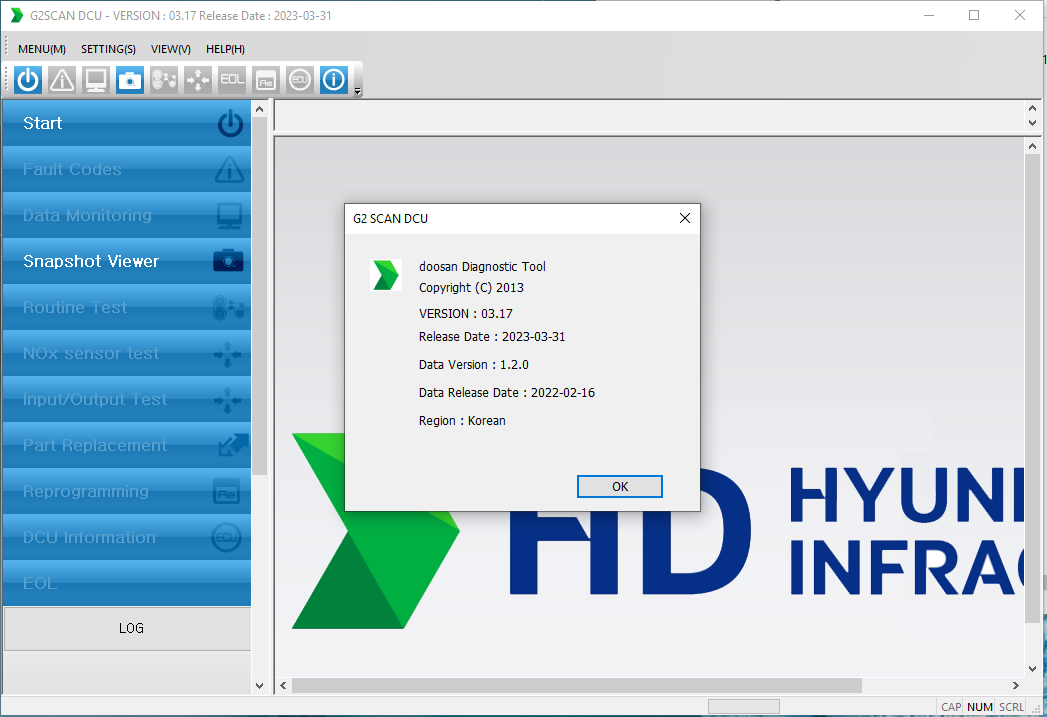

DOOSAN EDIA AS FULL STANDARD 2.4.0.7 [2023.06] : Your Essential Diagnostic Tool for Heavy Machinery

DOOSAN EDIA-AS FULL STANDARD 2.4.0.7 [2023.06] is an essential diagnostic software designed for Doosan machinery. Released in June 2023, it enhances maintenance and troubleshooting processes for heavy equipment. This version offers improved functionality, user-friendly features, and unlimited licensing. It also provides remote installation support via TeamViewer, ensuring users can maximize their investment effectively.

Table of Contents

ToggleOverview of DOOSAN EDIA-AS Software

The DOOSAN EDIA-AS software has become an essential tool for professionals in the heavy machinery sector. It provides comprehensive diagnostic capabilities that support diagnostics, maintenance, and overall functionality of Doosan equipment.

Importance in Heavy Machinery

The role of diagnostic software in heavy machinery cannot be overstated. Accurate diagnostics are critical for ensuring the reliability and efficiency of equipment. The DOOSAN EDIA-AS software enhances the operational capabilities of Doosan’s machinery through:

- Improved fault detection, which leads to reduced downtime.

- Enhanced maintenance strategies that facilitate proactive care.

- Access to extensive technical resources that empower users to make informed decisions.

Evolution of DOOSAN EDIA-AS

The DOOSAN EDIA-AS software has undergone significant transformations since its inception. Initial versions provided basic diagnostic functions, while recent updates have significantly enhanced its capabilities. The evolution includes:

- Enhanced user interface for easier navigation and usage.

- Increased compatibility with newer machinery models.

- Frequent updates that continuously improve functionality and introduce advanced diagnostic features.

Release History

The release history of the DOOSAN EDIA-AS software demonstrates the brand’s commitment to innovation and quality. Key milestones include:

- Initial launch, which laid the groundwork for future development.

- Introduction of major updates that addressed user feedback and technological advancements.

- The latest version, 2.4.0.7, released in June 2023, showcases substantial enhancements in performance and usability.

Key Features of DOOSAN EDIA-AS FULL STANDARD 2.4.0.7

The DOOSAN EDIA-AS FULL STANDARD 2.4.0.7 boasts a suite of features that enhances its usability and effectiveness in diagnosing and maintaining heavy machinery. Below are the specific details of its capabilities and functionalities.

Software Specifications

File Size

The software has a compact file size of 10.4 MB, ensuring quick download times and efficient use of storage space on your device.

Installation Size

Once installed, the software occupies 19 MB of space. This minimal installation size allows for easy integration with existing systems without consuming excessive resources.

Operating System Compatibility

DOOSAN EDIA-AS FULL STANDARD 2.4.0.7 is designed to operate seamlessly on Windows 11 (64 bits). This compatibility ensures that users can leverage the latest advancements in operating systems while benefiting from optimal performance.

Licensing Details

Duration of License

The software features an unlimited license duration. This means users can access all functionalities without the need for continuous renewals. Such a model enhances usability and reduces concerns regarding expiration.

Activation Process

The activation process for DOOSAN EDIA-AS is straightforward. Users simply need to follow a series of guided steps outlined during installation. A stable internet connection is recommended for a hassle-free experience.

Keygen Utilization

To activate the software, users will utilize the keygen provided alongside the installation files. This keygen allows for the verification of the software license and ensures legitimate usage.

Language Support

The software supports English as the primary language for its database. This multilingual support facilitates its application across various regions and enhances its accessibility for non-native speakers.

Regional Compatibility

DOOSAN EDIA-AS FULL STANDARD 2.4.0.7 is compatible across all regions, which allows technicians and mechanics worldwide to utilize it for their equipment without geographical restrictions. This feature promotes efficiency in diverse working environments.

The diagnostic capabilities of DOOSAN EDIA-AS FULL STANDARD 2.4.0.7 serve as a critical component for ensuring the optimal performance and reliability of heavy machinery. This section explores the extensive features and functions that facilitate precise diagnostics and maintenance support.

Diagnostic Capabilities

In-depth Diagnostics

This software provides advanced diagnostic tools that allow for thorough assessments of machinery performance. It integrates real-time data analysis, enabling technicians to gauge the operational status of equipment precisely. Users can access detailed logs and performance reports to identify irregularities efficiently.

Fault Identification

One of the standout features of the software is its ability to identify faults quickly. The system can analyze various parameters, such as engine performance metrics and operational histories, to pinpoint issues before they escalate into significant problems. By employing sophisticated algorithms, it provides actionable insights that help in decision-making.

Maintenance Support

Effective maintenance is key to prolonging the life of heavy machinery. The diagnostic capabilities include integrated maintenance support that assists users in managing both preventive and corrective maintenance tasks.

Preventive Maintenance

Preventive maintenance features proactively identify potential problems and recommend scheduled maintenance activities. By adhering to these recommendations, users can minimize downtime and reduce the risk of equipment failure. The software helps track maintenance schedules, ensuring that machinery remains in top condition through timely interventions.

Corrective Maintenance

In the event of unexpected machinery failure, the diagnostic tools provide valuable support for corrective maintenance. The software aids technicians in diagnosing the root cause of faults and facilitates efficient troubleshooting processes. This results in quicker resolution times and less disruption to operations.

Regular Updates

The software is designed to receive regular updates, which are essential for maintaining its efficacy. These updates may include improvements, new features, and enhanced diagnostic algorithms that adapt to emerging trends in heavy machinery technology. Staying current with updates ensures that users benefit from the latest advancements in diagnostic capabilities.

Access to Technical Information

Users have seamless access to a wealth of technical information through the software. This repository includes detailed documentation, repair manuals, and diagnostic guides that assist technicians in performing their tasks with greater efficiency. Such resources empower users to make informed decisions and tackle challenges with confidence.

Installation Process

The installation process of the DOOSAN EDIA-AS FULL STANDARD 2.4.0.7 is designed to be straightforward and efficient, ensuring that users can quickly set up the software on compatible systems. A proper understanding of each step is essential for a successful installation.

System Requirements

Before proceeding with the installation, it is crucial to ensure that the system meets the necessary requirements. The software is optimized to run on specific operating systems and configurations:

- Operating System: Windows 11 (64 bits)

- Processor: Minimum Intel i3 or equivalent

- RAM: At least 4 GB for smooth operation

- Disk Space: At least 20 MB of free disk space for installation

- Internet Connection: Required for activation and updates

Download Instructions

To acquire the software, follow these download instructions:

- Navigate to a reputable software vendor or distributor that offers DOOSAN EDIA-AS FULL STANDARD 2.4.0.7.

- Select the appropriate version that matches the system requirements.

- Click on the download link and save the installer file to a designated location on your computer.

Installation Steps

The installation process consists of several key steps that will walk the user through the setup procedure. Each step is important for a successful installation.

Running the Installer

Once the download is complete, run the installer by double-clicking the saved file. This action will initiate the setup wizard, guiding you through the installation.

Online Validation

During installation, an online validation process will occur to confirm the legitimacy of the software. Ensure that an active internet connection is available at this stage to avoid any interruption in the validation process.

Activation and Keygen Usage

After the installation is complete, users must activate the software to access its full functionality. This step is essential for enabling the unlimited license feature.

- Locate the keygen file provided with the software package.

- Run the keygen to generate a valid activation key.

- Input the generated key into the activation window within the software.

Troubleshooting Common Issues

Users may encounter some common issues during the installation process. Being aware of potential problems can save time and effort:

- If the installer does not start, ensure that the downloaded file is not corrupt and try re-downloading it.

- During online validation, check the internet connection if validation fails.

- If activation fails, verify that the keygen was used correctly and generate a new key if necessary.

- For issues with user permissions, run the installer as an administrator.

User Interface and Experience

The User Interface and Experience of DOOSAN EDIA-AS FULL STANDARD 2.4.0.7 is designed to enhance usability and efficiency in diagnostic processes. The intuitive layout and streamlined features cater to both new and experienced users, ensuring accessibility and ease of use throughout various tasks.

Design and Layout

The design of the software prioritizes clarity and functionality. It employs a clean and modern aesthetic, with a logical arrangement of tools and features. Color coding and visual cues are strategically used to guide users through different functions, creating an environment that minimizes confusion and maximizes productivity.

Key aspects of the design include:

- Intuitive Interface: The overall interface is structured to allow quick access to frequently used features.

- Responsive Design: Elements within the software scale and rearrange according to screen size, providing a seamless experience on various devices.

- Consistent Layout: Users will find uniformity in design, which helps reduce the learning curve when navigating through different sections.

Customization Options

Customizing the software allows users to tailor their experience, enhancing comfort and efficiency. Several options are available to suit personal preferences and workflow needs.

- Theme Selection: Users can choose color schemes that suit their work environment, which can help reduce eye strain.

- Tool Arrangement: Frequently used tools can be prioritized by arranging them on the dashboard, allowing users to streamline their workflows.

- Shortcuts: Keyboard shortcuts can be configured to expedite common tasks, enabling users to work more efficiently.

User-friendly Navigation

Navigation within the software is straightforward, designed to facilitate smooth user interactions. Each component is logically placed, allowing users to transition from diagnostics to reporting without unnecessary delays.

Notable features of the navigation include:

- Quick Access Menus: Frequently used features are easily accessible without deep navigation into the menu structure.

- Search Functionality: A robust search feature allows users to quickly locate tools, data, or functions, saving time in critical situations.

- Help and Support Access: Navigation to help sections is streamlined, ensuring users can find assistance and resources without interrupting their workflow.

Compatibility with Doosan Machinery

The DOOSAN EDIA-AS FULL STANDARD 2.4.0.7 software is designed to seamlessly integrate with a variety of Doosan machinery models. This compatibility enhances diagnostic capabilities and ensures efficient maintenance and support for operators using Doosan equipment. The software caters to different machine specifications, providing tailored functionalities for each model.

Supported Machine Models

This software supports a wide range of Doosan machinery, including but not limited to:

- Excavators

- Wheel Loaders

- Skid Steer Loaders

- Articulated Dump Trucks

- Telehandlers

These models are equipped with various systems requiring specific diagnostic tools, ensuring that users have the necessary support regardless of the equipment type. The software is built to recognize and adapt to the unique parameters of each machine, streamlining the troubleshooting process.

Specific Features for Different Machines

The DOOSAN EDIA-AS software includes several specialized features tailored to meet the needs of different Doosan machine models. These features improve the user experience and promote more effective maintenance routines:

- Customized Diagnostic Functions: Different models come with specific diagnostic functions that address common issues related to that machinery.

- Real-time Performance Monitoring: Users can monitor performance metrics specific to each machine, allowing for timely interventions when necessary.

- Comprehensive Fault Reporting: The software generates detailed reports that outline machine faults, facilitating quick resolution and minimizing downtime.

- Maintenance Alerts: Operators receive alerts regarding necessary maintenance for their specific machine models, helping ensure proper machine upkeep.

- Integration with Manufacturer Updates: The software remains updated with the latest manufacturer specifications and features, ensuring continued compatibility with new model releases.

This tailored approach not only enhances operational efficiency but also extends the lifespan of the equipment by ensuring it operates within optimal parameters.

Performance Enhancements in Version 2.4.0.7

The release of version 2.4.0.7 introduces a variety of performance enhancements that significantly improve the overall experience of the software. Enhanced speeds, a more intuitive user interface, and advanced analytical tools contribute to better diagnostics and maintenance workflows.

Improved Connection Speed

One of the standout upgrades in version 2.4.0.7 is the enhanced connection speed. Users will notice a quicker response when interfacing with machinery and diagnostic systems. This improvement minimizes downtime during maintenance reviews and helps technicians address issues more efficiently. Faster connection protocols and optimized data transfer processes ensure that time is effectively managed, leading to improved productivity on the job site.

Enhanced User Interface

The user interface has undergone significant enhancements to facilitate a smoother experience. The design focuses on clarity and ease of navigation, allowing users to quickly access necessary tools and features. Key improvements include:

- Redesigned layout that prioritizes essential functions.

- More intuitive menus that minimize the time spent searching for options.

- Improved visual graphics to make data interpretation simpler.

This user-centric approach ensures that even those who are new to the software can adapt quickly and utilize its full potential.

New Analysis and Reporting Functions

The introduction of new analysis and reporting capabilities in version 2.4.0.7 empowers technicians to conduct more thorough evaluations of machinery. These tools greatly enhance the ability to diagnose problems, thereby streamlining maintenance processes.

Generating Diagnostic Reports

Users can now generate comprehensive diagnostic reports that compile data from various tests and checks performed on the equipment. These reports are crucial for assessing the condition of machinery and determining the necessary maintenance actions. The new function allows for customizable report formats that meet diverse industry requirements. This capability helps clients maintain records for compliance and operational reviews.

Analysis Tools

Version 2.4.0.7 introduces upgraded analysis tools that can handle complex data sets and provide deeper insights into machine performance. These tools come equipped with features like:

- A predictive analysis framework that identifies potential failures before they occur.

- Real-time monitoring capabilities to track machinery conditions continuously.

- Simulation tools that predict how changes or repairs will affect machine operation.

These advancements allow technicians to make informed decisions and prioritize their maintenance tasks effectively. Enhanced analytical functions not only contribute to operational efficiency but also help reduce unexpected failures and associated costs.

Maintenance and Support

Maintaining optimal performance and support for the DOOSAN EDIA-AS software is crucial for maximizing its capabilities in diagnostic and maintenance tasks. A comprehensive support system ensures that users can effectively address any challenges that may arise during operation.

Remote Support Options

The DOOSAN EDIA-AS software provides flexible remote support options to assist users in resolving issues quickly and efficiently. This functionality ensures minimal disruption to operations, allowing for timely interventions as needed.

TeamViewer Installation Help

For users requiring immediate assistance, TeamViewer offers a simple solution for remote installation and troubleshooting. This tool enables support technicians to connect directly to the user’s device, facilitating step-by-step guidance through the installation process without the need for physical presence. Remote support sessions help identify issues in real-time, making solutions more accessible and faster.

Regular Software Updates

Continuous improvement is a hallmark of the DOOSAN EDIA-AS software. Regular updates are rolled out to enhance functionality, address bugs, and ensure compatibility with the latest machinery technologies. These updates not only introduce new features but also enhance the overall user experience by improving efficiency and diagnostic accuracy.

Access to Expert Technicians

Users benefit from the expertise of knowledgeable technicians who are available to provide support. This access includes troubleshooting assistance, guidance on best practices, and strategic advice to maximize the effectiveness of the software in various operational settings. The presence of seasoned professionals ensures that users can leverage the full potential of the software.

Online Documentation and Tutorials

A wealth of online resources, including documentation and tutorials, is available to facilitate learning and effective usage of the software. These resources cover a range of topics, from basic functionalities to advanced diagnostic techniques, empowering users to solve problems independently.

- Comprehensive guides outlining features and functionality

- Step-by-step video tutorials for visual learners

- Regularly updated FAQs addressing common inquiries and problems

These online materials are updated frequently to reflect new software versions and user feedback, ensuring that users always have pertinent, up-to-date information at their fingertips.

Integration with Other Systems

Integrating DOOSAN EDIA-AS FULL STANDARD 2.4.0.7 with other software systems expands its functionality and enhances productivity in heavy machinery management. Compatibility with various applications is essential for seamless operations and data management across platforms.

Compatibility with EPC Software

The DOOSAN EDIA-AS software is designed to work harmoniously with Engineering, Procurement, and Construction (EPC) software solutions. This integration allows for streamlined project management and communication between different teams involved in machinery upkeep and performance monitoring. Key benefits include:

- Facilitated data exchange between engineering and maintenance teams.

- Enhanced project tracking by aligning machinery diagnostics with project timelines.

- Streamlined reporting capabilities that aggregate data across multiple platforms.

With the integration of EPC software, users can anticipate maintenance needs more accurately, reducing downtime and ensuring that equipment is always operating at its best.

Integration with Existing Diagnostic Tools

This software is compatible with various existing diagnostic tools, providing flexibility for users who may already rely on certain technologies. Integrating these diagnostic solutions can offer a comprehensive view of the machinery’s condition. Important features include:

- Seamless data transfer for a cohesive diagnostic overview.

- Comprehensive reporting that combines diagnostics from multiple sources.

- Fewer redundancies in data entry, saving time and reducing errors.

Combining DOOSAN EDIA-AS with other diagnostic tools enhances the robustness of analysis and improves reliability in problem identification.

Data Export and Import Options

The export and import capabilities of this software facilitate efficient data management. Users can easily transfer diagnostic data to other systems or extract data for reporting purposes. Advantages include:

- Flexible data formats for compatibility with various applications.

- Ease of generating custom reports for internal and external stakeholders.

- Enhanced analytical capabilities with aggregated data from different sources.

These features ensure that users can maintain a clear and organized dataset for ongoing analysis and decision-making related to their heavy machinery.

Security Features

The security features of the software are essential for protecting user data and ensuring system integrity. Robust measures are put in place to safeguard against unauthorized access and potential data breaches.

Data Protection

Data protection is a critical component of any diagnostic software. This software implements several strategies to secure sensitive information:

- Encryption: All data transmissions are encrypted to prevent interception during communication. This ensures the confidentiality of the information exchanged between the software and external sources.

- Backup Solutions: Regular backups are scheduled to protect user data against loss. These backups are stored securely, enabling quick recovery in case of system failure.

- Data Integrity Checks: Periodic checks are conducted to ensure that data has not been tampered with or corrupted. This helps maintain the reliability of the information within the system.

Secure Access

Secure access is vital for maintaining control over who can use the software and how it is used. The following measures are in place:

- Role-Based Access Control: Users are granted access based on their roles within an organization. This minimizes the risk of unauthorized users accessing sensitive functionalities.

- Firewall Protection: A comprehensive firewall system is used to filter incoming and outgoing traffic, providing an additional layer of security against potential threats.

- Secure Connection Protocols: The software utilizes secure protocols for network communications, ensuring that data is transmitted safely over the internet.

User Authentication

User authentication processes are designed to ensure that only authorized personnel can access the software. The following methods are employed:

- Strong Password Policies: Users are required to create complex passwords, which enhances security by making it more difficult for unauthorized individuals to gain access.

- Two-Factor Authentication: In addition to passwords, a second layer of security is provided through two-factor authentication. Users must verify their identity using a secondary method, such as a mobile device.

- Session Monitoring: All user sessions are monitored for unusual activity. Any suspicious behavior triggers alerts to administrators to investigate potential security breaches.

Understanding the cost and availability of DOOSAN EDIA-AS FULL STANDARD 2.4.0.7 is crucial for businesses looking to invest in this diagnostic tool for heavy machinery. The following sections outline various purchasing options, recommended vendors, and information regarding warranties and returns.

Cost and Availability

Purchasing Options

When it comes to acquiring the DOOSAN EDIA-AS software, there are flexible purchasing options available to cater to different needs and budgets. These options include one-time purchases as well as subscription models that ensure continuous access to updates and support.

Single Purchase

A single purchase allows customers to buy the software outright with no recurring fees. This option is ideal for businesses that prefer a straightforward financial commitment. Once purchased, users have access to the full suite of features without the need for ongoing payments.

Subscription Models

For those who prefer a more dynamic approach, subscription models are also offered. These models provide users with regular updates and improvements as they are released. Subscriptions typically come with monthly or annual payment plans, allowing for flexibility in budgeting.

Recommended Vendors

Prospective users are encouraged to acquire DOOSAN EDIA-AS from reputable vendors to ensure they receive legitimate and updated software. Reliable vendors provide not only the software itself but also customer support and service agreements.

ecmtrucks.com

ecmtrucks.com is one of the recommended vendors for purchasing DOOSAN EDIA-AS FULL STANDARD 2.4.0.7. This platform is recognized for its commitment to customer satisfaction and offers a range of diagnostic tools and software tailored to the needs of the heavy machinery industry.

Warranty and Returns

Warranties and return policies vary by vendor but are important considerations during the purchasing process. Customers should always review the terms provided by the vendor to ensure they understand their rights and the support available after the purchase.

Typically, warranties cover defective products and provide a clear process for returns if the software fails to meet expectations. Understanding these policies helps businesses make informed decisions and provides peace of mind with their investment.

Customer Testimonials

Feedback from users provides valuable insights into the effectiveness and reliability of the software. Real-world experiences and success stories highlight the advantages it brings to heavy machinery diagnostics and maintenance.

User Experiences

Users have shared their experiences with DOOSAN EDIA-AS FULL STANDARD 2.4.0.7, emphasizing the software’s ease of use and efficiency. Many technicians appreciate the comprehensive diagnostic capabilities that allow for quick fault identification.

- One user noted, “The diagnostic tools are exceptional. I was able to troubleshoot a major issue within minutes, saving my team valuable time.”

- Another technician mentioned, “The user interface is intuitive. I didn’t need extensive training to get started. It’s straightforward and efficient.”

- Many have also praised the unlimited license duration, which eliminates concerns about frequent renewals and ongoing costs.

Case Studies

Several companies have adopted the software to enhance their operations. These case studies highlight specific instances where the software played a crucial role in improving performance and reducing downtime.

- Construction Company A: Implemented the software for their fleet of excavators and loaders. They reported a 30% decrease in maintenance-related downtime due to the timely diagnostics provided by the software.

- Agricultural Equipment Supplier B: Adopted the software as part of their equipment maintenance program. Their technicians were able to increase efficiency significantly, completing routine diagnostics in half the time it previously took.

- Mining Operation C: Noted that the ability to generate detailed reports using the new analysis functions improved communication with management, leading to better decision-making and resource allocation.

Success Stories

Success stories from various industries illustrate how the software has contributed to enhanced operational efficiencies. Users have experienced tangible benefits, which strengthen their overall maintenance strategy.

- One success story involved a fleet manager who stated, “Since we started using DOOSAN EDIA-AS, our ability to predict and prevent equipment failures has drastically improved. This has saved us thousands in repair costs.”

- Another user highlighted how access to regular updates kept their systems up to date with the latest diagnostic capabilities. “Staying current with software updates has allowed us to continuously improve our maintenance protocols,” they explained.

- Lastly, an equipment rental service mentioned, “Customers appreciate that we can quickly address any issues with their equipment. This has boosted our reputation and clientele.”

Frequently Asked Questions (FAQs)

This section addresses common questions regarding various aspects of the software to provide clarity and assist users in navigating their experience effectively.

General Inquiries

Users often have questions regarding the overall functionality and purpose of the software. Below are some frequently asked questions:

-

What is the main purpose of DOOSAN EDIA-AS FULL STANDARD 2.4.0.7?

The software is designed as a diagnostic tool for heavy machinery, particularly for models manufactured by Doosan. Its primary function is to facilitate preventive and corrective maintenance, ensuring optimal performance and reliability of the equipment.

-

Who can benefit from using this software?

Technicians, mechanics, and maintenance professionals within the heavy machinery sector will find the software particularly useful. It streamlines the diagnostic process, thus enhancing operational efficiency and reducing downtime.

Installation Issues

During the installation process, users may encounter common issues that can be easily resolved. The following questions address these potential hurdles:

-

What should I do if the installation fails?

In case of installation failure, ensure that your system meets the minimum requirements and that the operating system is compatible with the software. It may also be helpful to check for any error messages displayed during the process.

-

Is there support for remote installation?

Yes, remote installation support is available. TeamViewer can be utilized to assist users with installation issues, ensuring the software is set up correctly on their systems.

Activation and Licensing

Understanding the activation process and licensing terms is crucial for users. Common questions related to this aspect include:

-

How do I activate the software?

The activation process involves using the key provided with your purchase. Follow the on-screen instructions after installation to complete the activation. If you encounter issues, refer to the troubleshooting section in the documentation.

-

Is the license renewable?

The license for DOOSAN EDIA-AS FULL STANDARD 2.4.0.7 is unlimited. Users do not need to renew their licenses, allowing for continual use without the hassle of periodic renewals.

Diagnostic Functions

Questions related to the diagnostic capabilities of the software are common among users. Here are key inquiries:

-

What types of diagnostics can be performed?

The software enables in-depth diagnostics, including fault identification and performance analysis. It helps users assess machine health, ensuring timely maintenance and reducing the risk of unexpected failures.

-

Are there regular updates to the diagnostic functions?

Yes, the software receives regular updates to enhance diagnostic functions and introduce new features. This ensures that users always have the most current tools at their disposal to maintain their machinery effectively.

Terms and Conditions outline the legal agreements and guidelines that govern the use of the software. Understanding these terms is crucial for compliance and smooth operation.

Terms and Conditions

Licensing Agreement

The licensing agreement defines the terms under which the software may be used. It grants the user a non-exclusive, non-transferable license to use the software solely for personal or business purposes. The agreement stipulates that all intellectual property rights remain with the provider. Users must comply with all applicable laws and regulations related to the software’s usage.

Unauthorized reproduction, distribution, or modification of the software is strictly prohibited. Any violation of the licensing agreement may result in the termination of the license and legal action.

Usage Policies

Usage policies provide guidelines on how the software should and should not be used. Users are required to:

- Use the software in compliance with all local laws and regulations.

- Avoid using the software for any unlawful activities, including but not limited to fraud or harassment.

- Respect the rights of other users, ensuring that personal data is handled appropriately and securely.

- Report any security vulnerabilities or breaches immediately to the support team.

These policies are designed to promote a safe and productive environment for all users. Regular monitoring may be conducted to ensure compliance with these usage policies.

Support Terms

Support terms outline the type of customer support available to users. Technical support is offered to assist with installation, troubleshooting, and general inquiries related to the software. Support may be provided through various channels including documentation, online resources, and direct assistance as necessary.

The support team aims to resolve issues promptly and efficiently; however, response times may vary based on the volume of inquiries. Users are encouraged to utilize available online resources before reaching out for direct support.

Privacy Policy

The privacy policy describes how user data is collected, used, and protected. Personal information collected during registration or usage of the software is stored securely and is only used for the purposes outlined in the privacy policy. The software provider commits to not selling or sharing personal data with third parties without prior consent.

Users have the right to access their personal information and request corrections if necessary. Measures are in place to safeguard user data against unauthorized access and breaches, in compliance with applicable privacy laws.

Troubleshooting and Common Issues

Issues may arise when using the software. Understanding common problems and their solutions is essential for maintaining operational efficiency.

Installation Problems

Installation problems can occur due to various reasons, including system incompatibility or incorrect setup procedures. Common issues include:

- Incompatible Operating System: Ensure that the software is being installed on a compatible version of Windows, specifically Windows 11 (64 bits).

- Insufficient Disk Space: Verify that there is enough disk space available for the installation. The installation size is around 19 MB, and additional space may be required for updates.

- Corrupt Installer File: If installation fails, the installer file may be corrupted. Redownload the file from a trusted source.

Software Crashes

Unexpected software crashes can disrupt diagnostic processes. Resolving these issues quickly is important for continuous operation. The following could lead to crashes:

- Insufficient System Resources: Ensure that the computer meets the minimum hardware requirements to run the software effectively.

- Conflicting Software: Other applications running simultaneously might conflict with the DOOSAN EDIA-AS software. Close unnecessary programs while operating the software.

- Outdated Software Version: Ensure the software is up to date. Regular updates can fix bugs that may lead to crashes.

Connectivity Issues

Connectivity is crucial for diagnostic functions. If users experience connection issues, they may face challenges accessing certain features. Consider the following:

- Poor Internet Connection: A stable internet connection is required for online validation and updates. Check network stability and speed.

- Firewall Restrictions: Sometimes, firewall settings can block the software’s access to necessary servers. Adjust settings to allow the program to connect without restrictions.

- Device Compatibility: Ensure that all connected diagnostic devices are compatible with the software to maintain proper communication.

License Activation Errors

Errors during license activation can hinder the use of the software. Solutions to common activation issues include:

- Invalid License Key: Carefully check the license key for any typographical errors. A minor mistake can lead to activation failure.

- Expired License: Verify that the license is valid and not expired. The DOOSAN EDIA-AS FULL STANDARD software offers an unlimited license; however, it’s important to confirm its status.

- Activation Process Issues: Follow the activation steps precisely to avoid issues. If using a keygen, ensure it is legitimate and properly executed during installation.

Advanced Features

The advanced features of this diagnostic software significantly enhance its utility for professionals in the heavy machinery industry. These functionalities are designed to streamline operations, offer deeper insights, and improve overall efficiency.

Custom Reporting Tools

One of the standout features is the suite of custom reporting tools. Users can create tailored reports that focus on specific diagnostic outcomes. This is particularly beneficial for maintenance teams that require clear documentation of machine conditions and repair histories.

The custom reporting capabilities include:

- Options to select specific data points for focused reporting.

- Ability to generate reports in various formats, including PDF and Excel.

- Pre-set templates that can be modified to fit unique requirements.

- Scheduling options for automatic report generation and distribution.

These tools not only save time but also ensure that all relevant information is collected and presented in a clear, professional manner.

Advanced Analysis Functions

Advanced analysis functions enable users to dive deeply into the data collected from machinery diagnostics. These functions facilitate accurate fault identification and predictive maintenance strategies.

Key aspects of the advanced analysis include:

- Real-time data analysis that allows instant feedback on machinery performance.

- Graphs and charts to visualize trends over time, making it easier to understand performance metrics.

- Integration of historical data to compare past performance with current diagnostics.

- Tools for root cause analysis that help pinpoint underlying issues affecting machinery operation.

With these analysis functions, users can foster proactive maintenance approaches, which ultimately lead to increased uptime and reduced costs.

Integration with Construction Management Systems

The software’s ability to integrate seamlessly with construction management systems enhances its functionality, consolidating data from various operational aspects. This integration simplifies workflow and improves communication between different departments.

Integration features include:

- Direct linking with project management software to ensure machinery diagnostics are aligned with project timelines.

- Data synchronization across platforms for consistent information availability.

- Compatibility with popular construction management applications for easy data exchange.

- Enhanced reporting features that utilize data from both diagnostic tools and management systems for comprehensive project insights.

This level of integration not only boosts productivity but also ensures that all stakeholders have access to the same up-to-date information regarding equipment status and project demands.

Training and Resources

Training and resources are crucial for maximizing the effectiveness of the software. Understanding its features and functionalities through structured learning can enhance overall performance and efficiency.

Training Modules

The training modules are designed to provide comprehensive knowledge about the software’s functionalities. These modules cover a range of topics, ensuring users gain a deep understanding of the tools and options available to them. Key aspects include:

- Overview of Software Capabilities

- Step-by-step Guidance on Diagnostic Features

- Maintenance Protocols and Best Practices

- Case Studies Highlighting Practical Application

Each module allows users to progress at their own pace, enabling a customized learning experience. Users can easily track their progress and revisit specific topics as needed.

Video Tutorials

Video tutorials serve as visual aids in learning how to use the software effectively. These tutorials offer detailed demonstrations of various features, making complex concepts easier to understand. Key advantages include:

- Clear Visual Representation of Processes

- Accessible Anytime for Reference

- Tutorials Organized by Topic for Easy Navigation

- Expert Tips for Troubleshooting Common Issues

These resources ensure that users can visually engage with the software, making learning more effective and substantial.

Webinars and Workshops

Webinars and workshops provide live interactive sessions where users can learn directly from experts. These sessions cover advanced topics and allow users to ask questions in real time. Benefits include:

- Interactive Learning Environment

- Direct Interaction with Specialists

- Focus on Latest Updates and Features

- Networking Opportunities with Other Users

By participating in these events, users can stay informed about best practices and emerging trends relevant to the software. This interaction promotes a deeper understanding and application of the tools available.

Advantages Over Competitors

In the competitive landscape of diagnostic software for heavy machinery, several advantages set this product apart from others on the market.

Superior Diagnostic Capabilities

This software excels in delivering comprehensive diagnostic functionalities, enabling technicians to diagnose issues rapidly and accurately. Its advanced algorithms and real-time data processing facilitate:

- In-depth analysis of machine performance metrics.

- Quick fault identification, allowing for immediate corrective actions.

- Integration with various Doosan machinery models for tailored diagnostics.

These capabilities significantly reduce downtime and enhance operational efficiency, which are critical factors for companies reliant on heavy machinery.

User Experience

A user-friendly interface is another standout feature. The design prioritizes ease of navigation, ensuring that users can access critical utilities with minimal effort. Key aspects include:

- An intuitive layout that simplifies complex diagnostics.

- Customizable dashboard views for personal preferences, enhancing workflow efficiency.

- Helpful tutorials and documentation readily available within the software itself.

This focus on user experience promotes higher adoption rates among technicians, leading to better maintenance practices across the board.

Comprehensive Support

Robust support infrastructure is essential for maintaining the longevity and effectiveness of diagnostic software. This solution provides:

- Regular software updates that keep the system current with technological advancements.

- Accessibility to expert technicians for troubleshooting and guidance.

- Remote installation support via TeamViewer, streamlining setup processes.

The commitment to comprehensive support reinforces trust with users, ensuring that they can depend on the software for ongoing operational needs.

Future Updates and Roadmap

The roadmap for DOOSAN EDIA-AS FULL STANDARD 2.4.0.7 outlines the planned enhancements and features, ensuring the software remains at the forefront of diagnostic technology in heavy machinery.

Planned Features

Future updates will focus on several key features designed to improve functionality and user experience. Anticipated enhancements include:

- Advanced Diagnostics: Integration of AI-driven diagnostics to enhance fault identification accuracy.

- New Reporting Tools: Expanded options for generating custom reports tailored to user needs.

- Mobile Compatibility: Development of a mobile application interface to access diagnostic tools on the go.

- Integration with IoT Devices: Increased compatibility with IoT technology for real-time machine monitoring and diagnostics.

- Enhanced User Training Modules: More comprehensive educational resources, including interactive training sessions.

User Feedback Integration

User feedback plays a crucial role in shaping the direction of future updates. The development team actively gathers input from users to ensure the software evolves in line with actual needs.

Strategies for incorporating user feedback include:

- Surveys and Questionnaires: Regularly distributed to capture user sentiments and suggestions.

- User Forums: Online platforms where users can discuss their experiences and propose potential features.

- Beta Testing Programs: Inviting select users to test new features before their official release, allowing for early feedback and adjustments.

Development Timeline

The development timeline provides a clear view of when users can expect to see these updates implemented. Key milestones include:

- Q1 2024: Release of a beta version featuring newly integrated diagnostic tools.

- Q2 2024: Launch of mobile app compatibility for iOS and Android platforms.

- Q3 2024: Introduction of AI-driven features for enhanced diagnostic processes.

- Q4 2024: Deployment of upgraded training modules and user resources.

Effective support is crucial for maximizing the use of software solutions, especially for complex machinery diagnostics. This section outlines the various ways to seek assistance and ensure smooth operation of the system.

How to Contact Support

Support Tickets

The support ticket system allows users to submit detailed inquiries regarding any issues faced while using the software. By providing specific information about the problem, users can expedite the resolution process. Here’s how it works:

- Access the support ticket section through the official platform.

- Fill out the ticket form with relevant details, including software version, operating system, and a description of the issue.

- Submit the ticket and receive a confirmation of submission via your registered email.

- The support team will review the ticket and respond promptly with troubleshooting steps or solutions.

Direct Contact via ecmtrucks.com

For users seeking immediate assistance, direct contact through the ecmtrucks.com website is available. This method provides a straightforward way to reach out for help. Users can:

- Visit the “Contact Us” section on the website.

- Choose the relevant support category that corresponds to the issue at hand to ensure it is routed correctly.

- Provide all necessary details to facilitate a quicker response.

This approach is beneficial for urgent inquiries that require a quicker turnaround. Responses via this method are typically handled promptly by knowledgeable support staff.

Live Chat Options

Live chat options offer real-time support for immediate assistance. The chat feature connects users directly with a support agent who can address questions and troubleshoot issues on the spot. Here’s how to utilize live chat:

- Access the live chat feature on the ecmtrucks.com website during support hours.

- Type in your questions or concerns in the chat window.

- A support representative will join to assist you directly, allowing for a dynamic conversation about the troubleshooting steps or inquiries you may have.

This interactive support method ensures that users receive answers quickly, making it an efficient way to resolve issues without lengthy delays.

Related Products

Exploring additional software options can enhance operations and support various needs within the heavy machinery sector. The following related products offer complementary functionalities and features that can aid in diagnostics, maintenance, and overall machinery performance.

Other Doosan Software

Doosan offers various software solutions designed to work seamlessly with their machinery, ensuring efficiency and effectiveness in maintenance and diagnostics. These products include:

- Doosan Diagnostic Tool: This tool provides real-time insights into machinery performance, enabling quick identification of issues and facilitating prompt repairs.

- Doosan Fleet Management Software: A comprehensive tool for tracking equipment location, usage metrics, and maintenance schedules, aligning with best practices in asset management.

- Doosan Maintenance Management System: Designed to optimize maintenance processes, this software helps manage service schedules, parts inventory, and labor resources effectively.

- Doosan Training and Simulation Software: A platform that aids in the training of operators with realistic simulations, improving safety and operational competency on equipment.

Diagnostic Tools from ecmtrucks.com

As a trusted provider in the industry, ecmtrucks.com offers a range of diagnostic tools tailored for heavy machinery users. Their products ensure that technicians have the necessary resources to maximize performance and minimize downtime. Key offerings include:

- ecmtrucks Diagnostic Software: This versatile tool supports a wide range of heavy machinery diagnostics, providing detailed fault codes and repair instructions tailored to user needs.

- Fleet Management Tools: The software assists in monitoring multiple machines, streamlining maintenance schedules, and enhancing overall fleet efficiency.

- Remote Diagnostic Services: Utilizing remote assistance technologies, ecmtrucks.com can offer timely diagnostics and troubleshooting to clients, significantly reducing downtime.

- Custom Reporting Features: This innovative software provides in-depth reports on machinery performance and maintenance history, allowing for informed decision-making and strategic planning.

![11.png DOOSAN EDIA AS FULL STANDART 2.4.0.7 [2023.06] - Image 1](https://diagtrucks.com/wp-content/uploads/2024/11/11.png)