Hino DX3 2022 Diagnostic Software: Essential Tool for Truck Repairs

Hino DX3 2022 Diagnostic Software is a crucial tool for professionals working with Hino trucks. It enhances vehicle diagnostics by providing advanced features that streamline the repair process. This software allows technicians to read error codes, monitor real-time data, and customize engine settings. With its user-friendly interface, Hino DX3 improves efficiency and accuracy in diagnosing vehicle issues.

Table of Contents

ToggleUnderstanding Hino DX3 2022

The Hino DX3 2022 represents a sophisticated evolution in diagnostic tools designed specifically for Hino vehicles. Its comprehensive capabilities enable professionals to navigate complex diagnostic challenges efficiently.

Overview of Hino DX3

The Hino DX3 is an advanced diagnostic software that enhances the capability of technicians working on Hino trucks and buses. This tool provides access to a wide array of diagnostic functions that simplify the detection and resolution of vehicle issues. From reading sensor data to modifying specific parameters, the Hino DX3 empowers users with precise control over diagnostic procedures.

This software is engineered with flexibility in mind, allowing for extensive customization tailored to individual vehicle models. With an intuitive interface, technicians can learn to use the system quickly, optimizing their workflow and improving overall productivity in maintenance tasks.

Advancements from Previous Versions

Since its predecessors, the Hino DX2, the DX3 has seen significant enhancements that bolster its functionality. Key advancements include:

- Improved User Interface: The latest version features a more user-friendly layout that allows for easier navigation and faster access to key functions.

- Enhanced Diagnostic Capabilities: With upgraded algorithms, the DX3 can diagnose a broader range of issues with greater accuracy.

- Additional Customization Features: Technicians can now tailor various settings and parameters, such as speed limits and engine performance thresholds, to meet specific needs.

- Real-Time Data Monitoring: The ability to access live data provides mechanics with insights that were previously difficult to capture.

Key Benefits of Using Hino DX3

Utilizing the Hino DX3 offers numerous advantages for automotive professionals:

- Efficiency: The ability to quickly read and clear diagnostic trouble codes reduces downtime, allowing for faster turnaround on vehicle repairs.

- Cost-Effectiveness: Accurate diagnostics prevent unnecessary repairs and associated costs, providing long-term savings to workshops and fleet operators.

- Adaptability: The DX3’s compatibility with various models enhances its utility across different Hino vehicle lineups.

- Continuous Support: Regular software updates ensure that technicians have access to the latest improvements and database expansions.

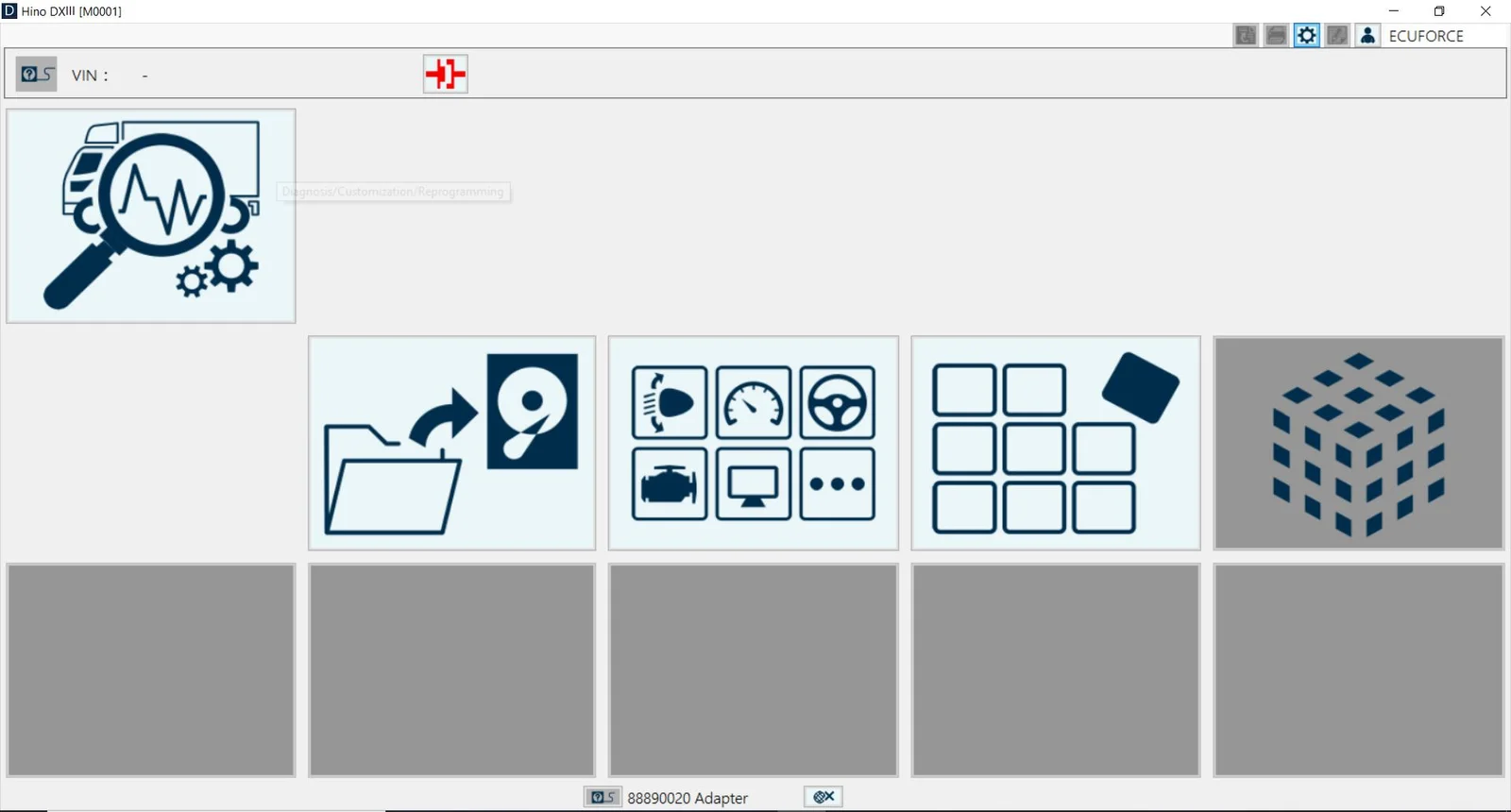

Core Features of Hino DX3

The Hino DX3 offers several key features that enhance its functionality and make it an essential tool for vehicle diagnostics.

Reading and Clearing DTCs

This feature enables technicians to read Diagnostic Trouble Codes (DTCs) directly from the Electronic Control Unit (ECU) of Hino trucks. By identifying these codes, professionals can quickly determine the underlying issues affecting the vehicle’s performance. Additionally, the ability to clear these codes facilitates an efficient troubleshooting process, allowing technicians to confirm if the issues have been resolved after repairs.

Real-Time Data Monitoring

Real-time data monitoring is a pivotal aspect of the Hino DX3. This feature allows users to observe a variety of live data streams from the sensors and actuators within the vehicle. By analyzing this live data, technicians can diagnose problems more accurately and efficiently. This capability is especially beneficial during test drives, where real-time feedback can lead to immediate insight into engine performance and other critical systems.

Activation Tests for Engine Components

The DX3 also provides activation tests for various engine components. This functionality allows technicians to manually activate certain parts, such as fuel pumps and injectors, to assess their operational status. By isolating individual components, it becomes easier to identify malfunctions that may not trigger error codes but still impact the vehicle’s performance. This targeted approach streamlines the diagnostic process and enhances repair accuracy.

Customization Options Available

Customization is a significant feature of the Hino DX3, allowing users to tailor the software settings to fit specific vehicle models and user preferences. This adaptability enhances the software’s utility across various scenarios.

Speed Settings and Engine Protection

Technicians can adjust speed settings and configure engine protection parameters through the customization options. This ensures that vehicles operate within specified limits, significantly reducing the risk of damage due to excessive speed or operational stress. This feature is crucial for operators managing fleets, as it allows for consistent control over all vehicles.

Injector Calibration Settings

Injector calibration settings are another important aspect of the customization functionality. This feature enables precise adjustments to be made for injector timing and flow, helping to optimize engine performance and efficiency. Proper calibration can lead to improved fuel economy and reduced emissions, making it a valuable tool for environmentally conscious operations.

Multi-Device Management

With the latest updates, the Hino DX3 has enhanced its capability for multi-device management. This means that technicians can monitor multiple vehicles or devices simultaneously, which significantly boosts productivity in busy workshops. This feature allows for a comprehensive overview of various diagnostics, making it easier to manage repairs across different trucks without needing to switch between devices constantly.

The following section outlines the technical specifications and requirements necessary for the effective installation and operation of the software.

Technical Specifications and Requirements

System Requirements for Installation

For optimal performance of the Hino DX3 2022 Diagnostic Software, specific system requirements must be adhered to. These requirements ensure compatibility and prevent performance issues. Key specifications include:

- Operating System: Windows 10 is the minimum requirement.

- Processor: A minimum processing speed of 2.0 GHz is recommended, although 700 MHz is the bare minimum.

- RAM: At least 256 MB of memory is needed, with 512 MB or more being optimal for better performance.

- Hard Drive Space: There must be a minimum of 20 GB of available space on the hard drive for installation and operation.

Compatible Operating Systems

Hino DX3 is designed to run exclusively on Windows operating systems. It ensures full compatibility for users who are utilizing modern computing environments. The main supported version is:

- Windows 10

This compatibility guarantees that users can quickly install and utilize the software on commonly used systems without encountering significant barriers.

Connectivity and Hardware Essentials

Establishing a proper connection between the Hino DX3 software and the vehicle’s ECU (Electronic Control Unit) is vital for functionality. The following hardware essentials are necessary:

- USB Port: A USB port is required to connect the software interface to the vehicle for diagnostics.

- Diagnostic Cable: A compatible diagnostic cable is essential for establishing a connection and is often included with software purchases.

- Internet Connection: Although not always necessary for core functionalities, an internet connection is beneficial for accessing updates and support resources.

These elements are crucial for ensuring that the software can communicate effectively with the vehicle’s systems, allowing for comprehensive diagnostic capabilities.

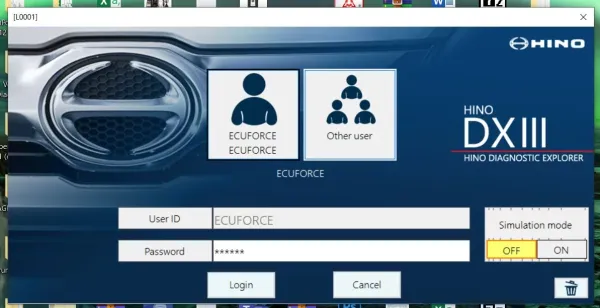

Installation and Setup Process

The installation and setup process for Hino DX3 is crucial for ensuring that the software operates smoothly on compatible systems. The following sections detail the required steps and support avenues available during installation.

Steps to Install Hino DX3

The installation of Hino DX3 involves several key steps to ensure that the software is set up correctly on a user’s PC. Following these steps minimizes potential issues:

- Ensure that the system requirements are met, including a compatible operating system such as Windows 10.

- Download the Hino DX3 installation file from the official Hino service website or authorized channel.

- Locate the downloaded file in the system’s downloads folder.

- Double-click on the installation file to launch the setup wizard.

- Follow the on-screen prompts to complete the installation process. This usually involves agreeing to terms and conditions and selecting an installation directory.

- Connect the interface device to the PC via USB before launching the software for the first time. Ensure that the device is properly detected by the system.

- Once installed, run the program and complete any required updates to ensure the software has the latest features and fixes.

Using Remote Support for Installation

For users who may encounter difficulties during the installation process, remote support is available to assist. This feature enables a qualified technician to access the user’s computer remotely to facilitate the setup.

- This support can be accessed through platforms like TeamViewer, where users can connect with a technician for real-time assistance.

- Technicians can guide users through installation steps, troubleshoot any issues, and ensure that the software is configured correctly.

- Using remote support can significantly reduce the time spent on installations and minimizes the likelihood of errors during setup.

Practical Applications and Usage

The Hino DX3 2022 Diagnostic Software offers a diverse range of practical applications that greatly enhance the efficiency of vehicle diagnostics and maintenance. Technicians utilize the software for various procedures to ensure optimal performance and reliability of Hino trucks.

Diagnostics and Testing Procedures

Using the Hino DX3, technicians can conduct comprehensive diagnostics on Hino vehicles. This includes:

- Reading and Clearing DTCs: The software allows for accurate identification of Diagnostic Trouble Codes (DTCs), which aids technicians in pinpointing the issues affecting vehicle performance. These error codes can be cleared once repairs have been made, streamlining the diagnostic process.

- Real-Time Monitoring: With capabilities to monitor engine data in real-time, the software facilitates immediate feedback on vehicle systems. Technicians can observe data from sensors and actuators while the vehicle is in motion, thus diagnosing issues with greater accuracy.

- Testing Components: The diagnostic software is equipped to perform activation tests on various engine components. This feature helps technicians verify the functionality of parts such as valves, injectors, and pumps, ensuring they operate as intended.

Module Reprogramming and Control

The Hino DX3 also supports module programming and control, allowing for the customization and reprogramming of various electronic control units (ECUs). Key aspects of this application include:

- ECU Updates: The software provides options for updating the firmware of ECUs, improving performance and adding new features to the vehicle’s systems.

- Configuration Adjustments: Programmable settings allow for specific adjustments tailored to the vehicle’s performance needs. This includes settings for speed limits and engine protection features.

- Calibration Procedures: Technicians can perform calibration of critical components, such as fuel injectors. This is essential for optimizing engine performance and fuel efficiency.

Maintenance Intervals and System Checks

Regular maintenance is crucial for the longevity and reliability of Hino trucks. The Hino DX3 assists in managing these maintenance requirements through:

- Interval Tracking: The software keeps a log of maintenance tasks and intervals, reminding technicians when services are due. This proactive approach ensures that vehicles remain in peak condition.

- System Diagnostics: Routine system checks can be performed to catch potential issues before they become significant problems. This can save time and costs associated with repairs and downtime.

- Comprehensive Reporting: After diagnostics and maintenance procedures, the software generates detailed reports that provide insights on vehicle performance and any issues detected, aiding in future maintenance planning.

Support and Resources

Access to support and resources is crucial for maximizing the efficiency and effectiveness of the Hino DX3 2022 Diagnostic Software. Users benefit from comprehensive technical support, structured training programs, and consistent updates that enhance the software’s capabilities.

Accessing Technical Support

Technical support for Hino DX3 users is designed to address a variety of issues that may arise during the software’s operation. Users can access support through several channels:

- Online Help Center: A detailed repository of FAQs, troubleshooting guides, and user manuals is available online, providing instant access to important information.

- Remote Assistance: Technicians can connect remotely to diagnose problems directly on the user’s system, ensuring quick resolution of issues.

- Email Support: Users can submit detailed inquiries through email, receiving prompt responses from knowledgeable staff who specialize in Hino products.

- Community Forums: Engaging with a community of users can provide insights and solutions as users share their experiences and tips related to Hino DX3 software.

Training Programs Available

To ensure that users are well-versed in utilizing the features of the Hino DX3 diagnostic software, various training programs are offered. These programs cover a range of topics, including:

- Basic Software Navigation: Training sessions help users navigate the interface, making it easier to access different functionalities.

- Diagnostic Techniques: Users learn effective strategies for diagnosing vehicle issues using the software’s advanced features.

- Customization Options: Programs emphasize how to tailor the software settings according to specific vehicle models for optimal performance.

- Hands-On Workshops: In-person workshops provide practical experience and direct interaction with instructors for real-time feedback.

Continuous Updates and New Features

Staying current with the latest updates is essential for users of Hino DX3. Regular updates introduce new features and improvements, ensuring the software remains efficient and user-friendly. Key aspects include:

- Feature Enhancements: New functionalities are added periodically to expand the diagnostic capabilities of the software.

- Bug Fixes: Updates often address reported issues, improving overall system stability and reliability.

- User Feedback Implementation: Suggestions from users are taken into account for future iterations, demonstrating a commitment to continuous improvement.

- Version Compatibility: Maintaining compatibility with the latest Hino vehicle models ensures that users have access to the most relevant diagnostic tools available.

User experiences and feedback play a crucial role in assessing the effectiveness and reliability of diagnostic tools. Understanding how users perceive the Hino DX3 2022 can provide valuable insights into its functionality and overall performance.

User Experiences and Feedback

Customer Reviews and Satisfaction

Many users have expressed their satisfaction with the Hino DX3 2022. Technicians and workshop owners highlighted several aspects that contributed to positive experiences with the software:

- Ease of Use: Users appreciated the intuitive interface, which simplifies navigation between features, making it accessible even for those with limited technical knowledge.

- Accuracy and Speed: Feedback indicates that the DX3 accurately diagnoses issues in a timely manner, significantly reducing the time spent troubleshooting.

- Comprehensive Features: The diverse functionalities, including real-time data monitoring and component activation tests, have been praised for enhancing diagnostic capabilities.

- Customer Support: Many users reported positive interactions with the customer support team, noting their responsiveness and helpfulness in resolving issues quickly.

Challenges and Solutions Noted by Users

While the Hino DX3 2022 has received favorable reviews, some users encountered challenges during its usage. Identifying these problems helped developers address concerns effectively:

- Installation Difficulties: Some users faced challenges during the installation process, especially those unfamiliar with software set up. To combat this, many relied on remote support services, which provided hands-on assistance and ensured successful installations.

- Connectivity Issues: A few users reported problems connecting to the ECU. These issues were often resolved through the provision of detailed guidelines and troubleshooting steps from support teams.

- Learning Curve: New users occasionally found it difficult to utilize all features efficiently at first. To overcome this, training programs were recommended to familiarize users with functionalities, ultimately enhancing their confidence in using the software.

Comparative Analysis with Hino DX2

The comparative analysis between Hino DX3 and its predecessor, Hino DX2, highlights significant improvements and changes in functionality, usability, and overall performance for users in the field of vehicle diagnostics.

Enhanced Features in Hino DX3

Hino DX3 has introduced several enhanced features that set it apart from DX2. These improvements have been well-received by technicians and mechanics who rely on precise diagnostics for efficient repairs.

- Advanced Diagnostic Capabilities: DX3 offers broader diagnostic coverage, enabling the identification of more complex issues within the electronic control units (ECUs) of Hino trucks.

- Real-Time Data Access: Users gain access to real-time data monitoring, which provides immediate insights into sensor performances and engine functions. This capability shortens troubleshooting time significantly.

- Customizable Settings: With the ability to customize engine parameters, technicians can adjust settings according to vehicle specifications, enhancing the adaptability of the software.

- Multi-Device Management: Unlike DX2, the DX3 allows for monitoring multiple devices simultaneously, making it easier to diagnose various vehicle components at once.

Usability Improvements and Interface Changes

The interface of Hino DX3 has undergone notable changes that promote a more user-friendly experience compared to Hino DX2.

- Simplified Navigation: The new user interface presents an organized layout that enables users to navigate between diagnostics tools and functions with ease.

- Intuitive Design: Enhanced visuals and a more intuitive design facilitate a quicker learning curve for new users, improving overall productivity.

- Responsive Performance: Improved speed and responsiveness in the software enhance the user experience, reducing lag time during diagnostics sessions.

The differences in usability and functionality clearly mark a progression from Hino DX2 to DX3, showcasing Hino’s commitment to advancing vehicle diagnostic software technology.

CLAAS

CLAAS CNH

CNH

HITACHI

HITACHI

JPRO

JPRO KUBOTA

KUBOTA MAGIC TUNER

MAGIC TUNER

MANITOU

MANITOU

NEXIQ

NEXIQ NONSELF

NONSELF PACCAR

PACCAR

PSI POWERLINK

PSI POWERLINK

ZF TESTMAN

ZF TESTMAN

Reviews

Clear filtersThere are no reviews yet.