TRUCK SOFTWARE

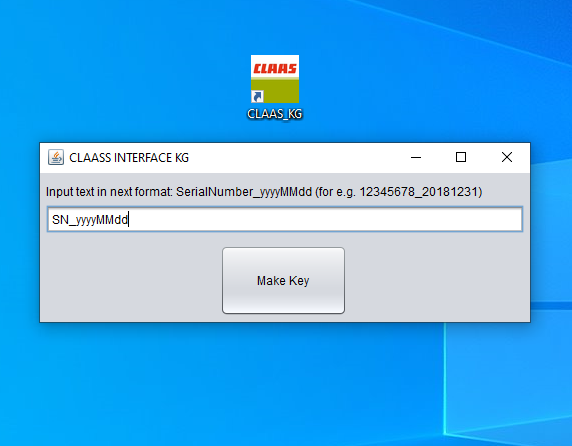

CLAAS

CLAAS CNH

CNH

HITACHI

HITACHI

JPRO

JPRO KUBOTA

KUBOTA MAGIC TUNER

MAGIC TUNER

MANITOU

MANITOU

NEXIQ

NEXIQ NONSELF

NONSELF PACCAR

PACCAR

PSI POWERLINK

PSI POWERLINK

ZF TESTMAN

ZF TESTMAN

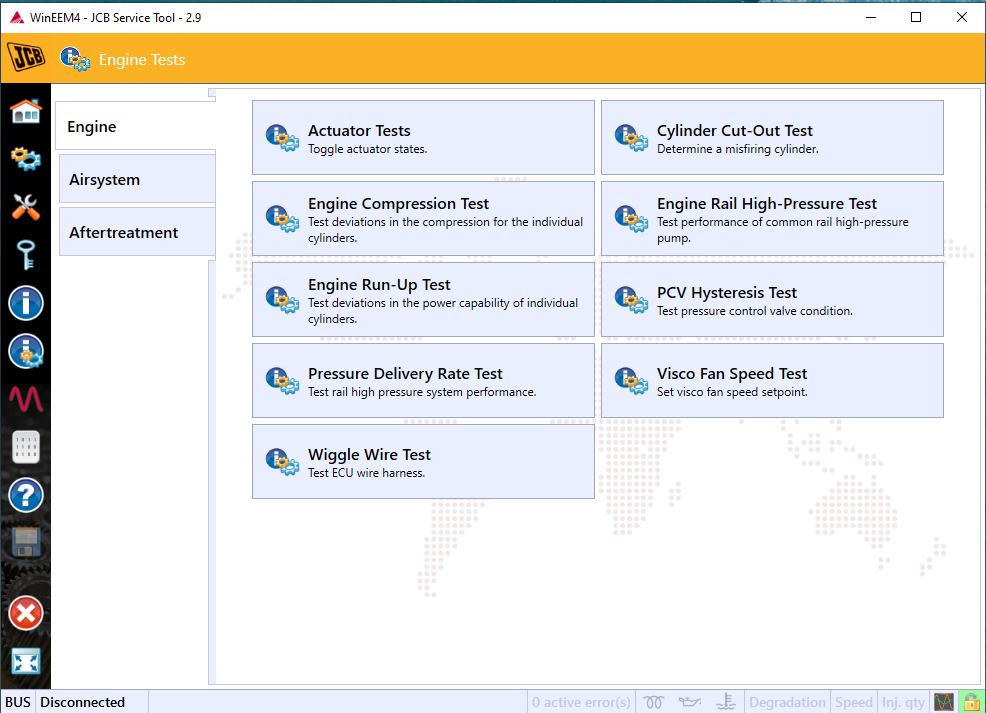

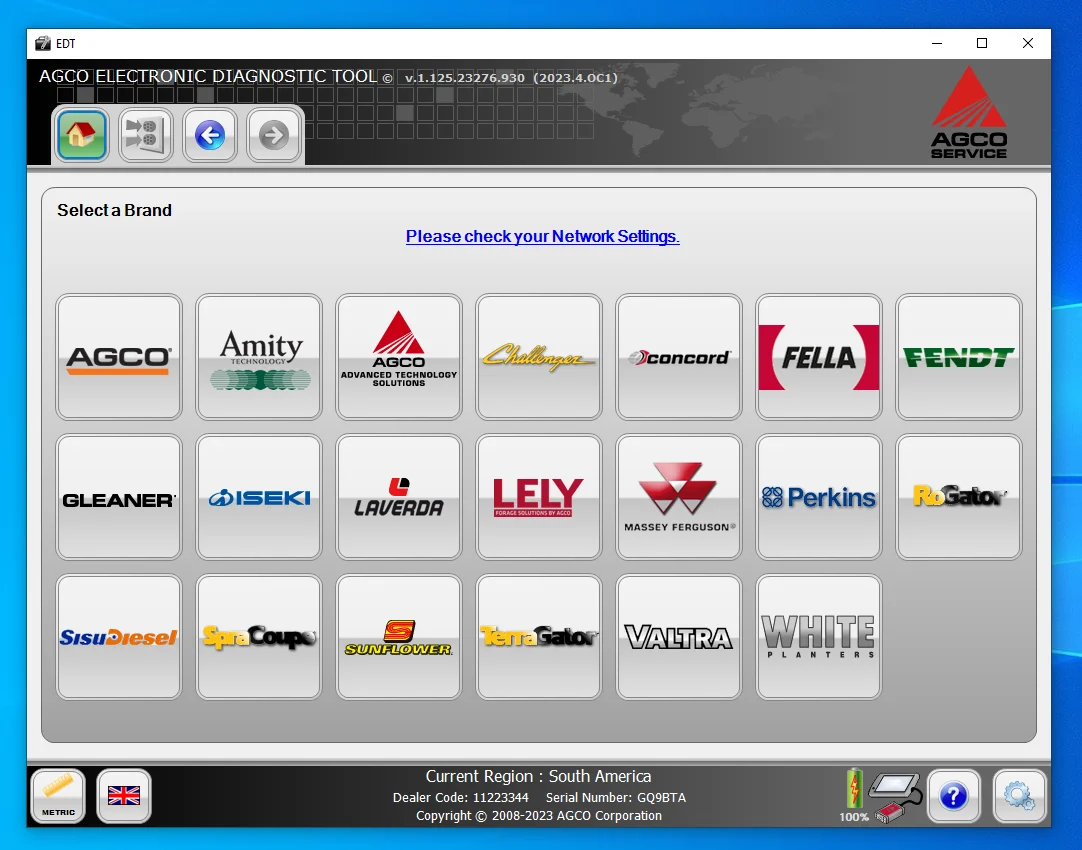

JCB AGCO SISU POWER WINEEM4 2.9: Essential Diagnostic Software for Heavy Machinery

JCB AGCO SISU POWER WINEEM4 2.9 is a diagnostic software solution used for monitoring and managing AGCO POWER engines. This tool is essential for technicians and mechanics working with heavy machinery and trucks. The software offers various features, including error code detection and real-time diagnostics. Its compatibility with multiple equipment types enhances its utility in the field of heavy machinery maintenance.

Table of Contents

ToggleUnderstanding JCB AGCO SISU POWER WINEEM4 2.9

This section provides insight into the JCB AGCO SISU POWER WINEEM4 2.9 and its functionalities. With advancements in technology, this software has become vital in maintaining engine performance and troubleshooting issues.

Overview of the Diagnostic Software

The JCB AGCO SISU POWER WINEEM4 2.9 software is designed for comprehensive engine diagnostics. It enables professionals to efficiently monitor and analyze engine parameters. Users can effectively identify problems, facilitating timely repairs and maintenance.

Key Features and Capabilities

- Real-time diagnostics that deliver immediate feedback on engine performance.

- Error code detection to accurately pinpoint issues within systems.

- Detailed analytics that help in understanding underlying causes and potential solutions.

- Intuitive user interface that allows easy navigation for both experienced technicians and novices.

Compatibility with Heavy Equipment

This diagnostic tool is designed to support a wide array of heavy machinery. Its compatibility extends to various models of agricultural and construction equipment. Moreover, the software integrates seamlessly with trucks and other large vehicles utilizing AGCO POWER engines.

Installation and Setup

Getting started with the software requires careful installation and setup to ensure optimal functionality. Following the necessary steps is crucial for a smooth operation.

System Requirements

Before proceeding, it is essential to verify that the system meets the following specifications:

- Operating System: Windows 11 (64-bit), Windows 10 (64-bit), or Windows 7 (32/64-bit).

- Available Disk Space: Minimum 115.00 MB for installation.

- RAM: At least 4 GB for efficient operation.

- USB Ports: One available port for connecting interfaces.

Step-by-Step Installation Guide

The installation of the diagnostic software can be completed in a few straightforward steps:

- Download the software from the official source.

- Run the installation file and follow the on-screen prompts.

- Read and accept the license agreement.

- Select the desired installation directory.

- Complete the installation process and restart the system if prompted.

Installation via TeamViewer

Migrating through TeamViewer is a convenient option for remote installation. This method allows an expert to assist in setting up the software efficiently:

- Ensure TeamViewer is installed on both local and remote machines.

- Establish a connection by sharing the TeamViewer ID and password.

- Follow the guided instructions provided by the remote technician.

Functional Capabilities

This software offers a range of advanced functional capabilities that streamline the diagnostic process for heavy machinery engines. These features enhance troubleshooting efficiency and offer clear insights into engine performance.

Real-time Diagnostic Functions

Real-time diagnostics allow users to monitor engine performance continuously. This functionality provides immediate access to vital parameters, enabling technicians to quickly identify issues as they occur. Key benefits of this feature include:

- Instant feedback on engine health

- Continuous monitoring of critical components

- Enables proactive maintenance strategies

Error Codes and Their Interpretations

Error codes play a crucial role in diagnosing mechanical problems. The software not only retrieves these codes but also supplies detailed interpretations that outline potential causes. This aids in understanding the effects on engine operation. Errors are categorized, making it easier for users to focus on specific issues.

CAN Bus Communication Support

Integrating with the Controller Area Network (CAN) facilitates robust communication between the diagnostic software and the vehicles’ electronic systems. This support ensures that all relevant data can be accessed seamlessly, allowing for:

- Efficient data transfer between modules

- Improved diagnostic accuracy

- Streamlined troubleshooting processes

Supported Vehicles and Machinery

The JCB AGCO SISU POWER WINEEM4 software is designed to support a wide variety of vehicles and machinery, ensuring compatibility across different sectors. This flexibility boosts operational efficiency and addresses the diverse needs of the heavy equipment industry.

Agricultural Equipment Compatibility

This diagnostic software works seamlessly with numerous agricultural machines, enabling farmers and technicians to maintain optimal performance. Key compatible equipment includes:

- Tractors

- Harvesters

- Planters

- Sprayers

Construction Machinery Integration

Heavy machinery used in construction can also benefit from the diagnostic capabilities of this software. It is compatible with various models such as:

- Excavators

- Bulldozers

- Loaders

- Crane trucks

Trucks and Other Heavy Vehicles

The software extends its support to trucks and other large vehicles, essential for efficient transportation and logistics. Notable examples include:

- Dump trucks

- Flatbed trucks

- Heavy-duty haulers

Benefits of Using JCB AGCO SISU POWER WINEEM4

This software offers several advantages that enhance operational efficiency and maintenance practices for heavy machinery users.

Enhanced Troubleshooting Efficiency

The diagnostic capabilities of JCB AGCO SISU POWER WINEEM4 streamline the troubleshooting process. By quickly identifying error codes and potential issues, technicians can resolve problems faster. The real-time feedback allows for prompt corrective actions, minimizing downtime.

Cost Savings in Maintenance

Utilizing this software can lead to significant savings on maintenance costs. Efficient diagnostics reduce unnecessary repairs and part replacements. Early detection of faults helps avoid more extensive damage, ultimately prolonging the lifespan of equipment and lowering overall operating costs.

Advanced Reporting and Analytics

The software includes comprehensive reporting features. Users can access detailed analytics on engine performance, allowing for informed decision-making regarding maintenance and modifications. This data-driven approach supports continuous improvement in operational practices.

Updates and Enhancements

Constant improvements ensure that users benefit from the latest advancements in diagnostic technology. The JCB AGCO SISU POWER WINEEM4 2.9 has seen several updates aimed at enhancing functionality and user experience.

Recent Software Updates

The most notable updates have focused on stability and compatibility. These refinements allow for smoother operation on various platforms, ensuring that technicians can rely on accurate data during diagnostics.

New Features in 2025

- Enhanced support for emission system diagnostics, specifically targeting NOx sensors.

- Introduction of detailed descriptions for error codes to simplify troubleshooting.

- Improvements in user interface design for better navigation and ease of use.

Planned Future Enhancements

The development team aims to include additional functionalities, such as:

- Integration of advanced analytics tools for better performance insights.

- Support for new models of machinery as they become available.

- Further enhancements in real-time data monitoring capabilities.

Frequently Asked Questions

This section addresses common inquiries related to the software, providing clarity on installation, troubleshooting, and support resources.

Common Installation Issues

Users may encounter various challenges during the installation process. Common issues include:

- Incompatibility with system requirements.

- Missing drivers for interface devices.

- Firewall settings preventing installation.

Ensuring that all necessary hardware and software prerequisites are met can alleviate many of these concerns.

Troubleshooting Guide

In the event of operational difficulties, the following steps may assist in resolving issues:

- Check for the latest software updates.

- Reset the communication interface.

- Consult the software’s error code descriptions for guidance on specific faults.

Implementing these troubleshooting methods often restores functionality.

Customer Support and Resources

Accessing support and resources is essential for effective software use. Available options include:

- Online user manuals and installation guides.

- FAQs on the official website.

- Community forums for peer assistance.

These resources promote a smoother experience with the software.

Purchasing and Downloading the Software

Acquiring the software is a straightforward process. Below are the essential steps for a successful purchase and download.

How to Buy the Software

The buying process is designed for convenience and efficiency. Users can purchase the JCB AGCO SISU POWER WINEEM4 2.9 software through the official sales platform. The steps include:

- Selecting the desired product, which in this case is the diagnostic software.

- Choosing a payment method, commonly either credit card or electronic payment services.

- Completing the transaction to finalize the purchase.

Download Link and Instructions

Upon successful payment processing, a direct download link will be provided. Users can follow these instructions for a quick setup:

- Click the download link to begin.

- Save the installation file to a designated folder on the computer.

- Open the file and follow the installation prompts on-screen.