Navistar Engine Diagnostics 2018 NED: Revolutionizing Engine Maintenance

Navistar Engine Diagnostics 2018 NED is a specialized software solution for diagnosing and programming Navistar engines. It provides critical tools to help technicians effectively maintain and troubleshoot engine issues in various applications. This article explores the key features of NED, its importance in reducing maintenance costs, and its effectiveness in enhancing fleet operations. It also compares NED with other diagnostic tools and discusses its applications across different sectors.

Table of Contents

ToggleUnderstanding Navistar Engine Diagnostics 2018 NED

This section provides insights into the capabilities and features of Navistar Engine Diagnostics 2018 NED, a critical tool for technicians working with Navistar engines.

What is Navistar NED?

Navistar Engine Diagnostics (NED) is a specialized software solution tailored for the comprehensive diagnosis and maintenance of Navistar engines. This tool enhances workflow efficiency, enabling technicians to deal with complex engine-related issues swiftly and accurately.

Key Features of NED 2018

The software includes numerous advanced features that enhance engine diagnostics. Key functionalities provide significant user advantages in managing engine health effectively.

Monitoring Control Systems

NED allows technicians to monitor the engine control systems in real time, ensuring optimal performance and prompt identification of any deviations.

Reading Diagnostic Trouble Codes

The ability to read Diagnostic Trouble Codes (DTC) is crucial for troubleshooting. NED retrieves these codes quickly, assisting technicians in diagnosing faults effectively.

Adjusting Engine Parameters

Another key feature involves adjusting engine parameters. This capability helps fine-tune engine performance based on specific operating conditions and requirements.

Data Analysis and Visualization

NED provides advanced data analysis tools that allow users to visualize engine performance metrics. Such insights are critical for informed decision-making regarding maintenance and repairs.

Importance of Effective Engine Diagnostics

Effective engine diagnostics play a crucial role in the overall maintenance and performance of vehicles. Accurate identification of issues can lead to significant improvements in operation and cost efficiency.

Reducing Maintenance Costs and Downtime

Timely diagnostics can prevent minor issues from escalating into major problems. By using advanced diagnostic tools, technicians can:

- Identify problems early, thus preventing extensive repairs.

- Optimize maintenance schedules to ensure vehicles are serviced only when necessary.

- Reduce the frequency of unplanned downtime caused by engine failures.

Improving Fleet Efficiency with NED

Integrating effective diagnostics within fleet management allows for seamless operations. Improvements in fleet efficiency include:

- Real-time monitoring of engine performance to streamline operations.

- Enhanced communication between systems, reducing response time to issues.

- Accurate assessments leading to quicker turnaround times for repairs.

Role in Vehicle Longevity

Effective diagnostics significantly contribute to the longevity of vehicles. Consistent engine monitoring promotes:

- Adequate maintenance that prevents wear and tear.

- Regular updates to software and diagnostic tools, ensuring vehicles operate within optimal parameters.

- A proactive approach to vehicle health, mitigating the risk of catastrophic failures.

Comparing NED to Other Diagnostic Tools

A detailed comparison of NED reveals its advantages over other diagnostic solutions available in the market. When evaluating diagnostic tools, several factors can influence their effectiveness in engine maintenance.

Ease of Use and User Interface

NED is designed with user-friendliness in mind. The interface simplifies navigation and allows technicians to quickly access necessary features. This ease of use is particularly beneficial for less experienced personnel, reducing training time and increasing operational efficiency.

Specialization for Navistar Engines

While many diagnostic tools cater to a wide range of vehicles, NED focuses specifically on Navistar engines. This specialization ensures:

- More accurate diagnostics tailored to the specific functionalities of Navistar engines.

- Enhanced performance tracking and troubleshooting capabilities.

- Access to engine-specific data that generic tools may not provide.

Support and Training by Triad

The support system provided by Triad significantly enhances the value of NED. This includes comprehensive training programs designed to equip technicians with the skills necessary to leverage the software effectively. Key components of this support include:

- Hands-on training sessions that improve familiarity with NED’s features.

- A responsive customer support team dedicated to resolving technical issues.

- Resources that help technicians stay updated on software advancements and best practices.

Application of NED in Different Sectors

The versatility of Navistar Engine Diagnostics allows it to be effectively utilized across a variety of sectors. Its specialized features cater to the unique needs of different industries, enhancing operational efficiency and reliability.

Use in Commercial Truck Fleets

In commercial trucking, the integration of NED has proven invaluable. Fleet managers benefit from:

- Real-time monitoring of engine performance.

- Immediate retrieval of diagnostic trouble codes to facilitate timely repairs.

- Efficiency in scheduling maintenance based on diagnostic data.

This proactive approach helps minimize downtime and reduce overall operational costs, ensuring that trucks remain on the road longer.

Agricultural Machinery Diagnostics

NED is also widely utilized in the agricultural sector, where it assists in maintaining various types of machinery. The key applications include:

- Monitoring engine health in tractors and harvesters.

- Quick diagnosis of operational issues during peak farming seasons.

- Fine-tuning engine calibration for optimal fuel efficiency.

Utilizing NED enhances the troubleshooting processes, ensuring that farmers can depend on their machinery during critical periods.

Off-Highway Applications and Benefits

Additionally, NED has significant applications in off-highway sectors such as construction and mining. Its capabilities include:

- Accurate diagnostics for heavy machinery to prevent unexpected failures.

- Customizable engine parameter adjustments based on specific site conditions.

- Support for compliance with emission regulations through effective aftertreatment diagnostics.

These features contribute to sustained equipment reliability and regulatory compliance, further validating the software’s role in diverse operational environments.

How NED Enhances the Service Bay Experience

The integration of Navistar Engine Diagnostics in service bays transforms the overall repair and maintenance workflow. Its specialized features significantly streamline diagnostics, ensuring faster turnaround times and enhanced service quality.

Specialized Service Bay Testing Features

NED offers a range of specialized testing features designed specifically for service bays. These capabilities facilitate efficient diagnostics, enabling technicians to perform tasks such as:

- Real-time monitoring of engine performance and parameters.

- Quick troubleshooting of electronic control systems.

- Remote diagnostics, reducing the need for technician presence at the vehicle.

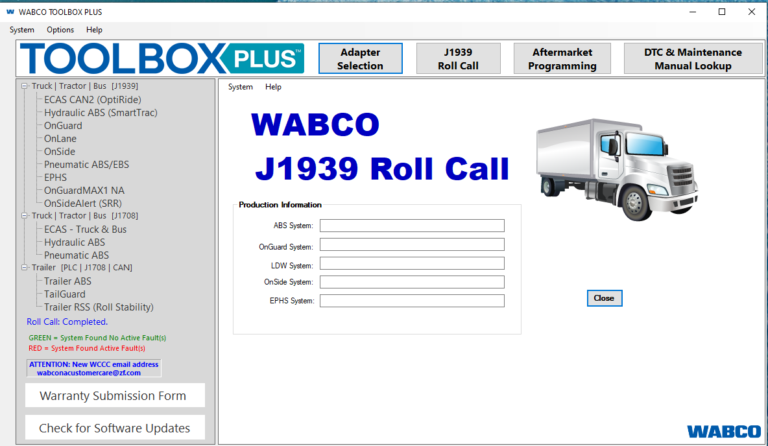

Utilizing J1939 International Electronic Systems

The J1939 protocol is a cornerstone of NED’s functionality, allowing seamless communication between diagnostic tools and engines. This integration enables technicians to:

- Access detailed data from the engine control units.

- Conduct comprehensive system checks across multiple vehicle components.

- Ensure compliance with industry standards through standardized communication.

Aftertreatment System Tests and Updates

NED also excels in handling aftertreatment system diagnostics. This includes crucial tests and updates that help maintain emission standards and system efficiency, allowing for:

- Monitoring of exhaust gas aftertreatment components.

- Updating software and parameters for optimal functioning.

- Performing diagnostic tests tailored to emissions control systems.

Future of Engine Diagnostics with NED

The evolution of engine diagnostics with Navistar Engine Diagnostics is crucial as the industry embraces new technological advancements. The integration of hybrid and electric vehicles into the marketplace necessitates innovative approaches in diagnosis and maintenance.

Adapting to Hybrid and Electric Vehicles

The rise of hybrid and electric vehicles presents unique challenges and opportunities for diagnostic tools. NED is evolving to incorporate functionalities specific to these vehicles, ensuring that technicians can effectively monitor and maintain their systems. Some adaptations include:

- Developing protocols to communicate with hybrid and electric powertrains.

- Integrating battery management system diagnostics.

- Establishing new standards for emissions testing in electric vehicles.

Upcoming Features and Updates in NED

Continuous updates are essential to keep the NED software relevant. Future features may involve:

- Enhanced data visualization tools for easier interpretation of diagnostics.

- Improved connectivity options for real-time updates and troubleshooting.

- New calibration settings specifically designed for emerging vehicle technologies.

Innovations in Engine Calibration and Programming

Future innovations in engine calibration and programming are key to maximizing engine efficiency and performance. NED is expected to introduce:

- Automated calibration processes that reduce manual intervention.

- Advanced algorithms for optimizing fuel efficiency and reducing emissions.

- Tools that allow for seamless integration with future vehicle architectures.

Success Stories and User Feedback

Several users have shared their experiences with the software, highlighting its impact on their operations and efficiency in diagnosing issues.

Case Study: Commercial Truck Repair Bay

A commercial truck repair bay in Indiana implemented the system and observed a remarkable reduction in diagnostic time. They reported a 30% decrease in the time taken to identify faults. This efficiency allowed them to serve more customers within the same timeframe, enhancing overall productivity.

Case Study: Agricultural Equipment Efficiency

In an agricultural setting, a repair workshop specializing in farming machinery found that the software dramatically improved their diagnostic capabilities. Technicians noticed they could pinpoint issues up to 50% faster compared to previous methods. This increase in speed not only improved their service quality but also resulted in higher customer satisfaction.

User Testimonials: Improving Diagnostic Accuracy

Feedback from users across various sectors consistently points to enhanced accuracy in diagnostics:

- Increased Precision: Many technicians observed that the tool allows for more accurate troubleshooting of engine problems, leading to better repair outcomes.

- Time Savings: Users reported significant reductions in the time taken to address repairs, allowing for quicker turnaround times for vehicles and equipment.

- Enhanced Training: The training provided alongside the software has empowered technicians to utilize the tool effectively, improving their skill sets and confidence.

Getting the Most Out of Your NED Software

Optimizing the use of NED software enhances diagnostic accuracy and operational efficiency. By leveraging training sessions, remote support, and effective troubleshooting techniques, users can significantly improve their experience and outcomes.

Training Sessions and Resources

Accessing comprehensive training sessions is crucial for maximizing the benefits of NED. These sessions often include:

- Hands-on workshops to practice real-world scenarios.

- Online tutorials and guides for easy reference.

- Webinars led by industry experts to stay updated on best practices.

Utilizing available resources ensures that technicians remain knowledgeable about the latest software updates and features.

Maximizing Remote Support Services

Remote support plays a vital role in maintaining workflow efficiency. Effective strategies to utilize remote services include:

- Scheduling regular check-ins with support staff to identify potential issues.

- Documenting common problems and solutions for quick access.

- Using real-time diagnostic tools to troubleshoot as issues arise.

Implementing these strategies enables faster resolution of technical challenges.

Effective Troubleshooting Techniques

Mastering troubleshooting techniques can lead to significant reductions in downtime. Techniques may consist of:

- Establishing a systematic approach to diagnosing problems.

- Staying organized by keeping detailed records of diagnostics performed.

- Utilizing data analysis capabilities to identify trends and recurring issues.

These techniques enhance the overall effectiveness of the diagnostic process, leading to improved performance and reliability.

CLAAS

CLAAS CNH

CNH

HITACHI

HITACHI

JPRO

JPRO KUBOTA

KUBOTA MAGIC TUNER

MAGIC TUNER

MANITOU

MANITOU

NEXIQ

NEXIQ NONSELF

NONSELF PACCAR

PACCAR

PSI POWERLINK

PSI POWERLINK

ZF TESTMAN

ZF TESTMAN

Reviews

Clear filtersThere are no reviews yet.