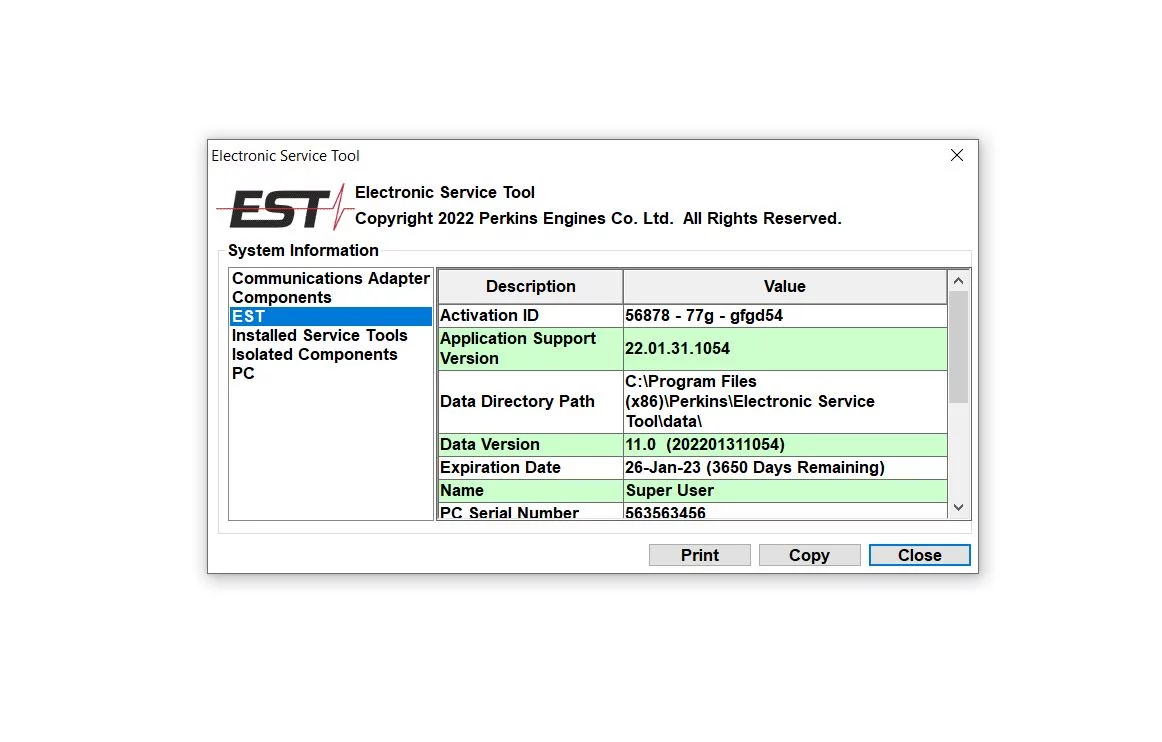

Perkins EST 2022A Diagnostic Software: Key Features and Benefits

Perkins EST 2022A Diagnostic Software is a vital tool designed for monitoring and maintaining Perkins engines. It aids technicians in diagnosing issues, optimizing performance, and ensuring long-term reliability of engines across various industries. This software integrates seamlessly with Perkins products, offering essential functions such as diagnostics, event logging, and parameter monitoring. Its features support efficient engine management and contribute to sustainability efforts in today’s energy-focused landscape.

Table of Contents

ToggleOverview of Perkins EST 2022A

The Perkins EST 2022A serves as a pivotal component in engine management and diagnostics, designed to enhance the efficiency and longevity of Perkins engines. This software integrates multiple functions that support technicians and professionals in the field.

Key Functions and Capabilities

The Perkins EST 2022A is equipped with a range of essential functions that provide comprehensive diagnostic capabilities. These features allow for a deeper understanding of engine performance and condition, fostering proactive maintenance strategies. Key functionalities include:

- Real-Time Diagnostics: Offers immediate insights into engine performance by displaying real-time data from the engine’s control modules.

- Event Logging: Captures and stores historical data regarding engine events, enabling users to track and analyze performance over time.

- Parameter Adjustments: Provides the ability to modify engine parameters according to specific operating conditions, enhancing overall efficiency.

- Reporting Features: Generates detailed reports summarizing diagnostics and performance metrics, useful for both documentation and client communication.

Role in Engine Maintenance

Effective engine maintenance is crucial in maximizing the lifespan and reliability of equipment. The Perkins EST 2022A plays a significant role by allowing technicians to perform detailed analyses that prevent potential failures. Regular use of the software supports:

- Preventive Maintenance: By identifying issues before they escalate, the software helps in scheduling timely maintenance tasks.

- Performance Optimization: Technicians can assess engine parameters and make necessary adjustments to improve efficiency and reduce emissions.

Integration with Perkins Products

This diagnostic software seamlessly integrates with a variety of Perkins engines, ensuring comprehensive support for different applications. Its compatibility with Perkins products enhances its functionality, allowing for:

- Unified Interface: Streamlined access to diagnostics across multiple engine models.

- Enhanced Support: A holistic approach to service and maintenance, improving the overall user experience.

- Consistent Updates: Access to the latest features and databases, ensuring that technicians are equipped with up-to-date tools for engine management.

Features of Perkins EST 2022A

The Perkins EST 2022A software is equipped with several features that enhance the diagnostic and maintenance processes of Perkins engines. The following sections outline its key functionalities.

Diagnostics and Event Logging

This feature allows users to access both active and recorded diagnostics from the engine’s Electronic Control Modules (ECMs). Diagnostics are critical to identifying trends and recurring issues. The event logging capability captures crucial data related to irregular engine behavior.

- Active diagnostics provide real-time insights into engine performance.

- Logged events enable technicians to track the history of issues, facilitating better troubleshooting.

Parameter Monitoring

Parameter monitoring is essential for maintaining optimal engine performance. The software provides a comprehensive view of various engine parameters to ensure everything operates within specified ranges.

- Simultaneous display of parameters such as temperature and pressure ensures efficient monitoring.

- Alerts for parameters that fall outside the optimal range help prevent potential engine damage.

Data Recording and Reporting

Data recording capabilities enable users to log performance data over time. This feature is crucial for making informed maintenance decisions based on historical performance trends.

- Users can easily generate reports that summarize engine performance data.

- These reports can be shared with stakeholders to promote transparency and informed decision-making.

ECM Configuration and Testing

The software’s ECM configuration feature allows users to modify the settings of the engine’s control modules. Tailoring these settings can optimize engine functionality based on specific operational needs.

- Technicians can perform diagnostic tests to ensure that ECMs are functioning correctly.

- Testing procedures help identify any configuration issues that may affect performance.

Password Access and Control

This feature is vital for maintaining control over engine configurations. The ability to access and change passwords enhances security and control over sensitive settings.

- Users can override higher-level passwords to make necessary adjustments to engine settings.

- This capability is particularly useful during maintenance operations where adjustments are needed rapidly.

System Requirements and Compatibility

Understanding the system requirements and compatibility of the software is essential for optimal performance and functionality. Meeting these criteria ensures seamless integration with various hardware setups, maximizing the efficiency of engine diagnostics and maintenance operations.

Supported Operating Systems

Perkins EST 2022A is designed to work with multiple versions of Microsoft Windows to accommodate a wide range of user needs. The compatible operating systems include:

- Windows 8

- Windows 10

- Windows 11

These supported operating systems facilitate effective communication between the software and the engine control modules. The ability to run the software on the latest Windows versions ensures users can take advantage of the latest updates and security features, enhancing overall system stability.

Required Hardware and Adapters

In addition to compatible software, specific hardware components and adapters are necessary for the software to function properly. Below is a list of hardware requirements:

- Computer Specifications:

- Intel i3 or equivalent processor

- Minimum 4GB RAM

- At least 1GB of free hard drive space

- Adapters:

- CAT ET DataLink Adapter III

- Nexiq USB Link (version 1 or 2)

The listed adapters play a critical role in establishing a communication link between the computer running the software and the associated engine control modules. Ensuring that the correct hardware is utilized avoids compatibility issues and allows for better diagnostic capabilities.

Advantages of Using Perkins EST 2022A

The Perkins EST 2022A offers numerous benefits that enhance the efficiency, performance, and sustainability of engine management in various industries. These advantages are crucial for operators seeking to maintain optimal operational conditions.

Increase Efficiency and Productivity

One of the standout features of the Perkins EST 2022A is its ability to boost operational efficiency. The software facilitates quick and accurate diagnostics, allowing technicians to identify issues before they escalate. This proactive approach minimizes downtime, which can be costly in industries reliant on machinery performance.

- Rapid issue identification streamlines maintenance processes.

- Improved diagnostics reduce the need for repetitive troubleshooting.

- Enhanced workflow allows for more productive use of equipment.

With this software, users experience a more organized maintenance schedule, ensuring that engines operate at peak performance and that any disruptions are managed swiftly.

Performance Optimization

Performance optimization is another significant advantage. By adjusting engine parameters according to real-time readings and historical data, users can tailor engine operations to specific needs. This capability leads to enhancements in efficiency, such as:

- Improved fuel consumption rates.

- Reduced emissions by fine-tuning engine settings.

- Customizable performance settings to match operational requirements.

Such adjustments contribute to not only a more efficient engine operation but also to reaching safety and regulatory standards required in various industries.

Support for Sustainability Goals

The Perkins EST 2022A is instrumental in supporting sustainability goals within organizations. It aligns with the increasing emphasis on reducing environmental impact and optimizing fuel usage. This software assists companies in adopting cleaner technologies and fuels.

- Facilitating the use of alternative fuels by optimizing engine performance.

- Encouraging practices that reduce carbon footprints through improved efficiency.

- Support for compliance with environmental regulations and standards.

Furthermore, the integration of innovative features within the software allows companies to monitor their progress towards sustainability, keeping goals in sight and ensuring accountability.

Perkins and the Energy Transition

The shift towards sustainable energy practices is a priority for Perkins, aligning with global trends in sustainability. The company is committed to innovating solutions that not only enhance engine performance but also contribute to reducing environmental impact.

Commitment to Renewable Fuels

Perkins has made significant strides in research and development focused on renewable fuels. This dedication is evident through several initiatives:

- Investment in alternative fuels, including biodiesel and renewable diesel.

- Collaboration with industry partners to promote fuel advancements and improved engine compatibility.

- Testing and validating engine performance using various sustainable fuel types.

These initiatives aim to ensure that Perkins engines operate efficiently with renewable options, reflecting the company’s mission to support the global transition to cleaner energy sources.

Achieving Lower Carbon Intensity

In pursuing its sustainability goals, Perkins focuses on developing engines that significantly reduce carbon emissions. The company implements technologies designed to:

- Enhance fuel efficiency and optimize combustion processes.

- Utilize advanced emission control systems that meet stringent regulatory standards.

- Improve overall engine performance, which in turn decreases greenhouse gas outputs.

By prioritizing lower carbon intensity, Perkins not only meets regulatory requirements but also actively contributes to combating climate change.

Collaborating with Customers for Sustainability

Perkins acknowledges that achieving sustainability goals requires active collaboration with its customers. To this end, the company is committed to:

- Providing comprehensive training and resources that help customers integrate sustainable practices into their operations.

- Offering tailored solutions that address specific needs regarding emissions reductions and fuel efficiency.

- Engaging in feedback loops to enhance product offerings based on customer experiences and expectations.

This collaborative approach ensures that both Perkins and its customers can achieve shared sustainability objectives, ultimately contributing to a more sustainable future.

Support and Services

Effective support and services are fundamental for maximizing the benefits of Perkins products. The support system is designed to provide thorough guidance and resources for users to ensure optimal performance and longevity of their engines.

Operation and Maintenance Manuals

The operation and maintenance manuals are essential documents that accompany every Perkins engine. They provide detailed instructions on how to operate and maintain the engines effectively. These manuals cover various topics, including:

- Starting and stopping procedures

- Routine maintenance tasks and schedules

- Troubleshooting common issues

- Safety precautions to follow during operation

By following the guidelines outlined in these manuals, users can ensure that their engines remain in optimal condition, minimizing unexpected failures and downtime. Access to these manuals is typically available both in printed form and through digital platforms, ensuring that they can be easily referenced when needed.

Advisory and Assistance

Perkins offers advisory services to support users in their maintenance and operational strategies. This assistance includes expert consultations that cover:

- Optimal maintenance practices

- Diagnosis of complex issues

- Enhancements to operational efficiency

These advisory services aim to impart best practices that help users get the most out of their Perkins engines. Users can benefit from specialized knowledge that enhances their understanding of engine performance and maintenance.

Case Studies and Success Stories

Perkins showcases various case studies and success stories that demonstrate the effectiveness and reliability of their products. These real-world examples highlight how businesses have successfully integrated Perkins engines into their operations. They serve as a testament to the durability, efficiency, and performance enhancements that Perkins products can offer.

- Examples from the agricultural sector illustrating reliable engine performance in demanding conditions.

- Case studies from construction companies that improved productivity through timely maintenance and diagnostics.

- Success stories from the energy sector showcasing sustainability initiatives supported by Perkins engines.

These narratives empower potential users by providing insights into how Perkins engines can be leveraged across different industries.

Protection Plans and Warranties

To further enhance user confidence, Perkins offers various protection plans and warranties designed to safeguard the investment in their engines. These plans may cover:

- Comprehensive service agreements that ensure regular maintenance.

- Extended warranty options that offer coverage beyond the standard terms.

- Protection against unforeseen mechanical failures, ensuring peace of mind.

Such plans are tailored to fit the specific needs of users, allowing for flexibility and tailored solutions that can adapt to various operational demands. Ensuring that maintenance is covered not only aids in budgeting but also contributes to prolonging the lifespan of the engines.

Applications Across Industries

The versatility of Perkins EST 2022A Diagnostic Software makes it invaluable across various sectors. Its ability to enhance engine performance and reliability has wide-ranging implications in multiple industries.

Agriculture Sector

In the agriculture industry, vehicles and machinery often operate under demanding conditions. Perkins EST 2022A plays a pivotal role in ensuring that agricultural equipment functions optimally during critical seasons. The software facilitates maintenance by:

- Providing real-time diagnostics to identify potential issues before they escalate.

- Recording performance data to help farmers monitor machinery efficiency.

- Allowing adjustments to equipment settings for improved fuel efficiency during diverse agricultural tasks.

As a result, farmers can minimize downtime and maximize productivity during busy harvest periods.

Construction Industry

In construction, every minute counts. Heavy machinery must be reliable and efficient to avoid costly delays. Perkins EST 2022A assists construction companies by:

- Monitoring engine health to prevent mechanical failures on-site.

- Enabling quick diagnostics which reduce repair times significantly.

- Supporting the calibration of equipment according to job specifications, optimizing performance for various tasks.

This capability ensures that projects remain on schedule and within budget, an essential requirement in the competitive construction sector.

Electric Power Generation

The demand for reliable power generation makes the electric power sector heavily reliant on efficient engine performance. Perkins EST 2022A contributes to this industry by:

- Monitoring engine parameters to ensure stable and efficient power output.

- Facilitating data logging that helps in compliance with environmental regulations by tracking emissions.

- Assisting with preventive maintenance to prolong the operational life of generating sets.

This enhances reliability in power supply, crucial for sustaining essential services and industries.

Equipment Rental Services

In the equipment rental sector, a variety of machinery is used across different applications and environments. Perkins EST 2022A helps rental companies by:

- Providing diagnostic reports that inform maintenance schedules, reducing equipment downtime.

- Allowing for the customization of engine settings based on the specific needs of various clients.

- Helping ensure that all rented machinery meets operational standards before being deployed.

This ensures client satisfaction and enhances the reputation of rental services as reliable providers of high-performance equipment.

CLAAS

CLAAS CNH

CNH

HITACHI

HITACHI

JPRO

JPRO KUBOTA

KUBOTA MAGIC TUNER

MAGIC TUNER

MANITOU

MANITOU

NEXIQ

NEXIQ NONSELF

NONSELF PACCAR

PACCAR

PSI POWERLINK

PSI POWERLINK

ZF TESTMAN

ZF TESTMAN

Reviews

Clear filtersThere are no reviews yet.