Perkins Software: Power up Your Equipment with Electronic Service Tool EST 2016C

The Perkins Software Electronic Service Tool EST 2016C offers advanced technology and innovative solutions for efficient equipment maintenance. With its data management capabilities, it enhances performance and supports sustainability goals. Collaborating with customers, Perkins ensures effective software utilization through product support and real-life case studies. This tool allows for seamless maintenance across a wide range of equipment and facilitates the transition to electronic service for emissions control. Discover the power of Perkins Software Electronic Service Tool EST 2016C in maximizing equipment efficiency.

Overview of Perkins Software Electronic Service Tool EST 2016C

The Perkins Software Electronic Service Tool EST 2016C is a cutting-edge technological solution designed to revolutionize equipment maintenance processes. Powered by advanced technology and innovative solutions, this tool offers a wide range of features and capabilities to enhance performance and streamline maintenance operations.

With its comprehensive data management system, Perkins Software Electronic Service Tool EST 2016C enables efficient tracking and analysis of equipment performance. This empowers businesses to make well-informed decisions and optimize maintenance strategies to ensure maximum productivity and longevity of their equipment.

One of the key advantages of Perkins Software Electronic Service Tool EST 2016C is its contribution towards sustainability and energy transition goals. By utilizing this tool, companies can effectively monitor and manage their equipment’s emissions control, reducing their environmental impact and supporting a greener future.

In addition to its technical capabilities, Perkins understands the importance of customer support and collaboration. The software comes with dedicated product support services, ensuring smooth implementation and utilization. Moreover, customers can benefit from real-life case studies and success stories that showcase the tool’s effectiveness in diverse maintenance scenarios.

Experience the power of Perkins Software Electronic Service Tool EST 2016C in action as it helps businesses unleash the full potential of their equipment and achieve unparalleled efficiency. Say goodbye to traditional maintenance techniques and embrace the future of equipment servicing with this state-of-the-art software solution.

Understanding Perkins Electronic Service Tool EST 2016C Features and Capabilities

Advanced Technology and Innovative Solutions

The Perkins Electronic Service Tool EST 2016C incorporates cutting-edge technology and offers innovative solutions for equipment maintenance. With advanced diagnostic capabilities, it provides in-depth analysis and troubleshooting, allowing for efficient repairs and minimizing downtime.

This tool utilizes the latest software advancements to ensure compatibility with a wide range of equipment models. It delivers real-time data and precise diagnostics, enabling technicians to address any issues promptly and accurately. With Perkins Electronic Service Tool EST 2016C, you have access to advanced technology solutions that streamline maintenance processes and enhance overall performance.

Data Management and Performance Enhancement

Data management is a critical aspect of efficient equipment maintenance, and Perkins Electronic Service Tool EST 2016C excels in this area. It offers comprehensive data collection and storage capabilities, allowing technicians to track equipment performance, monitor trends, and identify potential issues before they escalate.

By effectively managing equipment data, the tool enables proactive maintenance planning, optimizing uptime and reducing costly breakdowns. It also facilitates performance enhancement through data analysis, providing insights for fine-tuning equipment operation and maximizing efficiency.

With data management and performance enhancement features, Perkins Electronic Service Tool EST 2016C empowers you to make informed decisions, improve equipment reliability, and achieve optimal performance levels.

- Advanced technology for efficient equipment maintenance

- Innovative solutions for accurate diagnostics and troubleshooting

- Real-time data and precise analysis for prompt issue resolution

- Compatibility with diverse equipment models

- Comprehensive data collection and storage capabilities

- Proactive maintenance planning and trend analysis

- Performance enhancement through data-driven insights

- Optimized equipment reliability and efficiency

Experience the power of Perkins Electronic Service Tool EST 2016C’s advanced technology and data management capabilities, enhancing your equipment’s performance and reducing maintenance costs.

Benefits of Using Perkins Electronic Service Tool EST 2016C

Achieving Sustainability and Energy Transition Goals

The Perkins Electronic Service Tool EST 2016C empowers businesses to achieve their sustainability and energy transition goals. By utilizing advanced technology and innovative solutions, this tool helps optimize equipment performance, leading to reduced energy consumption and environmental impact. With real-time data monitoring and analysis, operators can identify inefficiencies and implement proactive measures to enhance sustainability efforts.

Supporting Customer Maintenance and Performance

Perkins Software Electronic Service Tool EST 2016C provides comprehensive support for customer maintenance and performance needs. Its user-friendly interface enables efficient equipment diagnostics, troubleshooting, and repairs, minimizing downtime and maximizing productivity. The tool offers access to a wide range of service resources, including manuals, bulletins, and software updates, ensuring smooth operation and long-term reliability.

- Streamlined equipment maintenance and servicing

- Enhanced performance monitoring and optimization

- Reduced downtime and increased productivity

- Access to valuable service resources and updates

- Improved customer satisfaction and loyalty

Achieving Sustainability and Energy Transition Goals

The Perkins Electronic Service Tool EST 2016C enables businesses to align with sustainability and energy transition goals by optimizing equipment performance, reducing energy consumption, and minimizing carbon footprint. By leveraging advanced technology and innovative solutions, operators can proactively address environmental concerns and contribute to a greener future.

Supporting Customer Maintenance and Performance

Perkins Software Electronic Service Tool EST 2016C supports customer maintenance and performance by providing intuitive diagnostics, efficient troubleshooting, and comprehensive repair guidance. With easy access to service resources and updates, operators can ensure equipment longevity, minimize interruptions, and maximize operational efficiency.

Collaboration with Customers for Effective Software Utilization

Collaborating with Customers for Product Support

At Perkins, we understand the importance of providing exceptional customer support for our Electronic Service Tool EST 2016C. We collaborate closely with our customers to ensure effective utilization of the software and offer comprehensive product support. Our dedicated team of experts is always available to answer any questions, provide guidance, and address any technical issues that may arise.

Through collaborative efforts, we aim to provide our customers with the knowledge and resources they need to maximize the benefits of Perkins Electronic Service Tool EST 2016C. Whether it’s troubleshooting software functionalities or offering training sessions, our priority is to ensure that every user has a seamless experience with our tool.

Case Studies and Success Stories

We believe in showcasing the success stories of our customers who have leveraged Perkins Electronic Service Tool EST 2016C to enhance their maintenance operations. Our case studies highlight real-life examples of how this software has helped companies overcome challenges, optimize equipment performance, and save valuable time and resources.

Through these case studies, you can gain insights into how Perkins Electronic Service Tool EST 2016C has been deployed in various industries and how different customers have successfully integrated it into their maintenance processes. These success stories serve as inspiration and provide practical examples of the software’s effectiveness in real-world scenarios.

Perkins Electronic Service Tool EST 2016C in Action

The Perkins Electronic Service Tool EST 2016C empowers users to utilize the widest portfolio of features for effective equipment maintenance. With a comprehensive range of tools, technicians can streamline their workflows and ensure optimal performance. Let’s explore two key aspects of the tool:

Utilizing the Widest Portfolio for Effective Maintenance

Perkins Electronic Service Tool EST 2016C offers a diverse range of diagnostic and maintenance functions to address various equipment needs. From engine diagnostics to parameter adjustments, users can efficiently troubleshoot and resolve issues. Additionally, the tool provides access to service information, including wiring diagrams and parts catalogs, facilitating accurate maintenance and minimizing downtime.

Transitioning to Electronic Service for Emissions Control

In today’s environmentally conscious world, emissions control is crucial. The Perkins Electronic Service Tool EST 2016C aids in the transition from traditional manual service to electronic service, simplifying emissions control tasks. By leveraging the tool’s capabilities, users can monitor emission levels, analyze data, and make necessary adjustments for compliance. This transition ensures equipment operates at optimal efficiency while meeting strict environmental regulations.

In summary, the Perkins Electronic Service Tool EST 2016C enables users to harness a wide array of features for efficient equipment maintenance. By utilizing its comprehensive portfolio and transitioning to electronic service for emissions control, technicians can ensure optimal performance and meet environmental standards.

AGCO

AGCO ALLISON

ALLISON BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CAT

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT DOOSAN

DOOSAN EATON

EATON FREIGHTLINER

FREIGHTLINER HINO

HINO HITACHI

HITACHI HYSTER

HYSTER ISUZU

ISUZU JCB

JCB JOHN DEERE

JOHN DEERE JPRO

JPRO KUBOTA

KUBOTA MAGIC TUNER

MAGIC TUNER MAN

MAN MANITOU

MANITOU NAVISTAR

NAVISTAR NEXIQ

NEXIQ NONSELF

NONSELF PACCAR

PACCAR PALFINGER

PALFINGER PERKINS

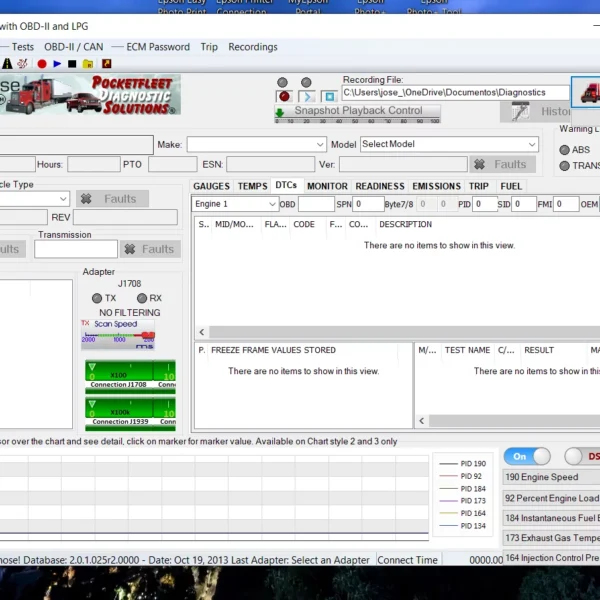

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA TAKEUCHI

TAKEUCHI THERMO KING

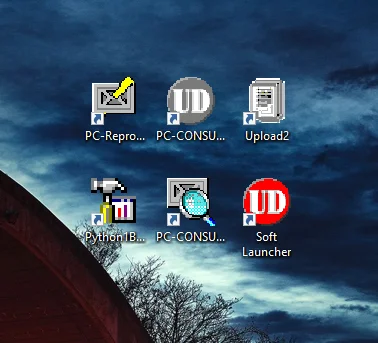

THERMO KING UD NISSAN

UD NISSAN VOLVO

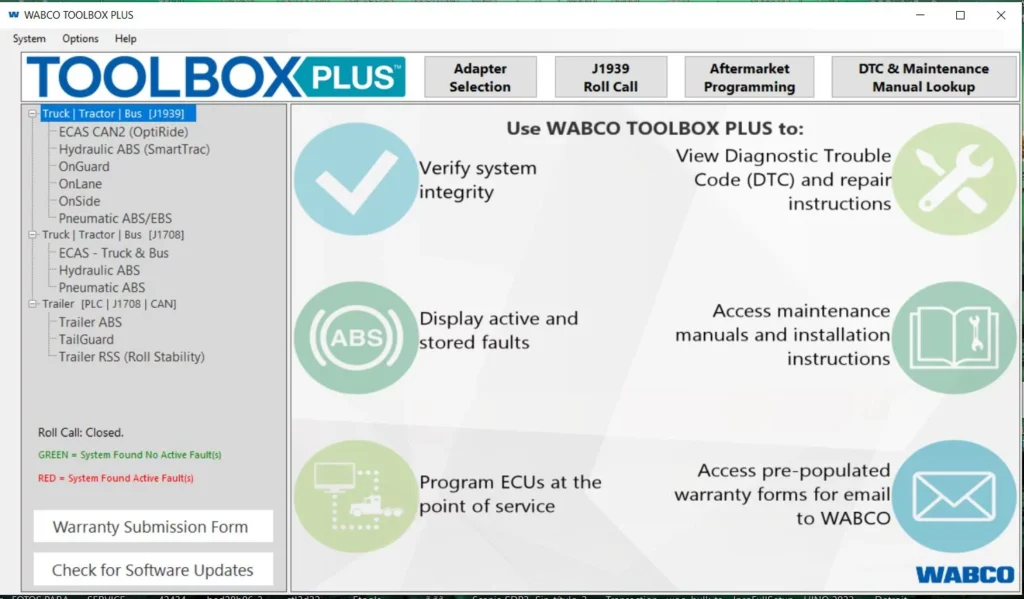

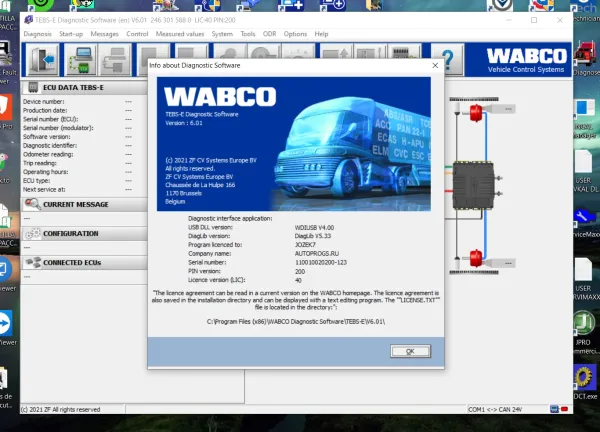

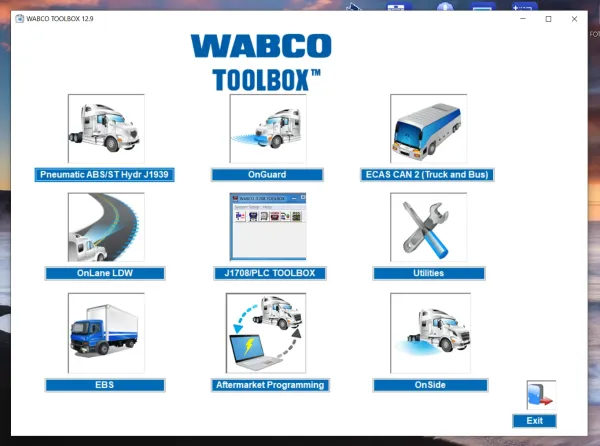

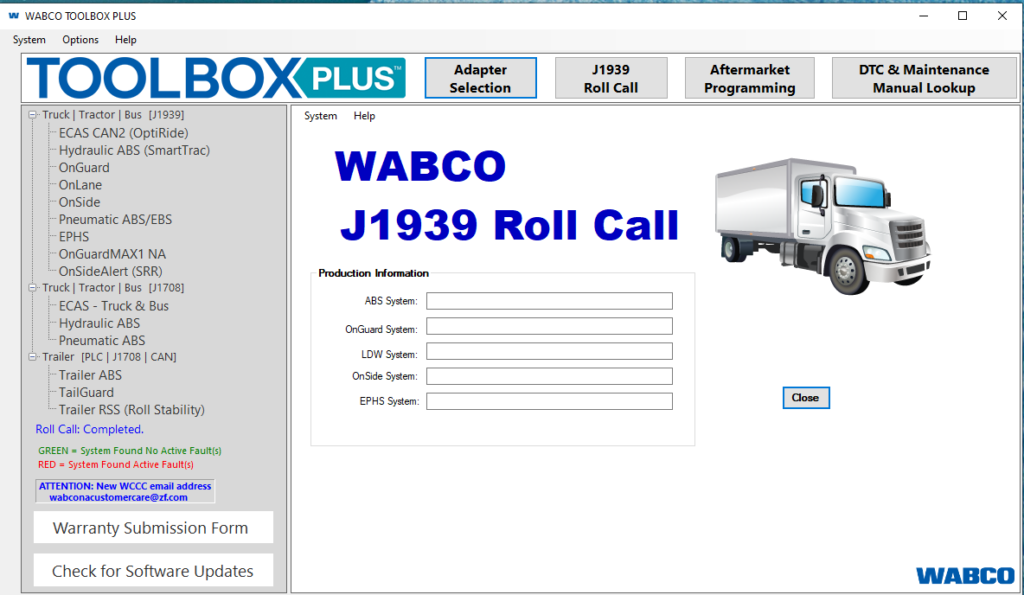

VOLVO WABCO

WABCO YALE

YALE ZF TESTMAN

ZF TESTMAN

Reviews

Clear filtersThere are no reviews yet.