PSI Powerlink 2 3 1 Diagnostic Software: Enhance Engine Diagnostics Effortlessly

PSI Powerlink 2.3.1 Diagnostic Software is an essential tool for diagnostics on PSI engines. It offers quick diagnostic functions and specific tools tailored for engine maintenance. This software provides valuable information for technicians in the field. Its capabilities streamline the troubleshooting process, making it easier to identify and address engine issues efficiently.

Overview of PSI Powerlink 2.3.1

The PSI Powerlink 2.3.1 offers essential tools for diagnosing PSI engines efficiently and effectively. This overview highlights its key features, competitive advantages, and practical applications within the industry.

Features of PSI Powerlink

- Custom trouble codes tailored specifically for PSI engines enhance troubleshooting accuracy.

- Real-time diagnostics allow technicians to monitor engine performance instantly.

- Quick diagnostic capabilities deliver results in under one minute, saving valuable time.

- Information about engine calibration and CVN details is readily accessible.

Advantages Over Competitors

The PSI Powerlink 2.3.1 stands out in a crowded market due to several significant benefits:

- Specialization in PSI engines ensures more relevant diagnostic tools than generalist competitors.

- Faster diagnostics reduce downtime, aligning with industry demands for efficiency.

- User-friendly interface enhances technician productivity through ease of navigation.

Use Cases in the Industry

This software is utilized in various scenarios across the machinery sector:

- Heavy-duty vehicle maintenance workshops leverage its rapid diagnostic tools to minimize repair times.

- Fleet management teams use the software to ensure optimal performance and regulatory compliance.

- Independent mechanics benefit from its cost-effective solutions for precise engine repairs.

The technical specifications of the software define its compatibility and operational efficiency. Understanding these details is crucial for optimal performance.

Technical Specifications

System Requirements

To ensure seamless operation, it is essential that users meet specific system requirements. These are:

- Operating System: Windows 10 or 11 (64-bit)

- Disk Space: At least 1 GB of free space on the hard drive

- RAM: Minimum of 4 GB for optimal performance

- Internet Connectivity: Required for updates and additional support

Installation Process

The installation process for the software is straightforward, designed to be user-friendly for technicians of varying skill levels. Key steps include:

Download and Setup

- After purchasing the software, users receive a link for downloading the installation file.

- The file is typically packaged as a .rar archive, which must be extracted using software such as WinRAR or 7-Zip.

- Once extracted, the installation can be initiated by running the installer and following on-screen prompts.

- During the setup, users can customize installation preferences based on their needs.

Remote Install Options

For organizations managing multiple vehicles or locations, the software may support remote installation options. This functionality allows technicians to set up the software across various systems without physical interaction, enhancing efficiency in fleet management.

Supported Operating Systems

The software is designed to operate effectively on specific platforms. It is primarily compatible with:

- Windows 10 (64-bit)

- Windows 11 (64-bit)

Ensuring that these operating systems are in place will help maximize the software’s capabilities and reduce potential issues during operation.

Diagnostic Capabilities

The diagnostic capabilities of PSI Powerlink 2.3.1 are tailored to ensure efficient engine assessments. It is designed to provide rapid and accurate diagnostics that help technicians address issues with PSI engines effectively.

Quick Diagnostic Functions

This software emphasizes speed and efficiency, allowing for diagnostics to be completed in under a minute. This quick functionality is crucial for minimizing downtime in heavy machinery. By simplifying the diagnostic process, technicians can swiftly move towards repairs and maintenance.

Specific Diagnostic Tools

PSI Powerlink includes a suite of specialized tools aimed at troubleshooting specific issues encountered with PSI engines.

Custom Trouble Codes

The software showcases customized trouble codes unique to PSI engines. This feature streamlines the diagnosis process by providing specific error codes that guide technicians in identifying problems accurately.

Real-Time Diagnostics

The real-time diagnostics capability allows for immediate observation of engine performance issues. Technicians can monitor active faults as they occur, enhancing the diagnostic process and reducing the need for extensive testing procedures.

PSI Engine Specific Features

Dedicated PSI engine features further enhance the software’s utility in the field.

Provides PSI Engine Information

To assist in troubleshooting, the tool delivers detailed information about the PSI engine itself. This data is critical for understanding engine-specific characteristics and requirements, aiding technicians in their evaluation processes.

Calibration and CVN Details

Calibration and Calibration Verification Number (CVN) details are vital for ensuring that the engine performs at optimal levels. This function helps technicians confirm that the necessary adjustments have been made, leading to better overall engine performance.

Comparison with Other Diagnostic Software

In the competitive landscape of diagnostic software for heavy machinery, several alternatives exist. Each has unique features tailored to specific needs within the industry.

JPRO Diagnostics

JPRO Diagnostics is known for its extensive compatibility across various vehicle makes. This software excels in providing comprehensive diagnostic capabilities, coupled with robust post-sale support. Users appreciate its detailed troubleshooting guides and ease of use, especially for multi-brand fleets. JPRO’s ability to deliver a wide array of repair recommendations makes it a favored choice for many technicians.

Detroit Diesel Diagnostic Link

Detroit Diesel Diagnostic Link (DDDL) is a specialized tool primarily designed for Detroit Diesel engines. It offers exceptional features for managing diagnostics and troubleshooting. While DDDL provides significant benefits for Detroit Diesel products, its limited compatibility with other brands can be a drawback. This software is often favored by workshops focused solely on Detroit Diesel machinery.

Bendix ACom and Allison DOC®

Bendix ACom and Allison DOC® are notable for their targeted functions within their respective brands. These tools are particularly advantageous for users dealing with Bendix and Allison systems. They provide deep insights into their specific performance metrics while ensuring compliance with manufacturer standards. However, professionals who work with diverse brands may find these tools less versatile compared to a more generalized diagnostic software.

User Experience

The user experience of this diagnostic software is integral to its effectiveness and adoption in the field. Comprehensive feedback from technicians highlights various aspects of interaction with the software.

Interface and Usability

The interface of the software is designed to be intuitive and user-friendly. Technicians appreciate the streamlined layout, which allows for quick navigation through various features. Key elements include:

- Clear categorization of diagnostic tools

- User-friendly information display

- Customizable dashboard settings

This simplicity enhances usability, reducing the learning curve for new users while allowing experienced technicians to work efficiently.

Technician Feedback

Feedback from technicians using the software is predominantly positive. Users often cite:

- Fast problem identification and resolution

- The reliability of generated data

- Effective communication of complex diagnostics

Such insights help in building confidence among users regarding the software’s capabilities, affirming its place in regular maintenance tasks.

Support and Updates

Access to robust support and timely updates is crucial for maintaining performance. Technicians report satisfaction with the support services available, which include:

- Responsive customer service

- Regular software updates to enhance functionality

- Access to online resources and troubleshooting guides

These aspects contribute to a positive user experience, fostering confidence in the continued use of the software in varying operational contexts.

Market and Availability

The availability and pricing structure of this diagnostic software are key considerations for professionals in the field. Understanding the options for purchase and access can facilitate better decision-making for users.

Price and Accessibility

PSI Powerlink 2.3.1 offers competitive pricing relative to similar diagnostic tools. Users can expect a straightforward pricing model that reflects the advanced capabilities of the software. Accessibility is enhanced since it is available for immediate download, eliminating potential delays associated with physical shipments. This convenience helps users get started without unnecessary wait times.

Download and Subscription Options

The software is available for direct download upon completion of the payment process. Users receive a link that provides access to the installation file, ensuring a seamless acquisition experience. Subscription options may also be available, which can include periodic updates and access to customer support. These options cater to different user needs and preferences.

Related Products and Services

In addition to PSI Powerlink 2.3.1, there are various complementary products and services that enhance the overall effectiveness of diagnostics for heavy machinery. Some related offerings may include:

- Extended customer support services

- Additional mechanic tools that bolster diagnostic processes

- Training programs designed for technicians to maximize the software’s capabilities

These products and services provide users with a comprehensive toolkit for maintaining and servicing heavy equipment efficiently.

FAQs and Common Concerns

Frequently asked questions and common concerns help address potential issues users may encounter with the software. Understanding these can enhance the overall experience and effectiveness of the diagnostic tool.

Troubleshooting Errors

When using PSI Powerlink 2.3.1, users may encounter various errors during operation. Common troubleshooting steps include:

- Ensuring the software is running with the latest updates installed.

- Verifying proper connection to the engine’s diagnostic port.

- Checking system compatibility with specified requirements.

- Restarting the software or the connected device to refresh the system.

If issues persist, consulting the support documentation or user guide can provide additional insights into resolving errors.

Compatibility Questions

Compatibility with different operating systems and hardware setups is crucial for effective diagnostics. The software primarily supports:

- Windows 10 and 11 (64 bits).

- Devices that meet the minimum hardware requirements of 4GB RAM and 1GB of disk space.

Users should confirm their systems align with these specifications before installation to prevent performance issues.

Remote Tuning Services

Remote tuning services provide an effective means to adjust engine settings without needing to be physically present at the location. This feature can significantly assist:

- Individual owners who want personalized support.

- Tuning shops aiming to maximize efficiency through remote diagnostics.

- Fleet managers requiring swift solutions without downtime.

Recognizing the availability of such services can enhance the utilization of the diagnostic software, improving overall engine performance.

AGCO

AGCO ALLISON

ALLISON BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CAT

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT DOOSAN

DOOSAN EATON

EATON FREIGHTLINER

FREIGHTLINER HINO

HINO HITACHI

HITACHI HYSTER

HYSTER ISUZU

ISUZU JCB

JCB JOHN DEERE

JOHN DEERE JPRO

JPRO KUBOTA

KUBOTA MAGIC TUNER

MAGIC TUNER MAN

MAN MANITOU

MANITOU NAVISTAR

NAVISTAR NEXIQ

NEXIQ NONSELF

NONSELF PACCAR

PACCAR PALFINGER

PALFINGER PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA TAKEUCHI

TAKEUCHI THERMO KING

THERMO KING UD NISSAN

UD NISSAN VOLVO

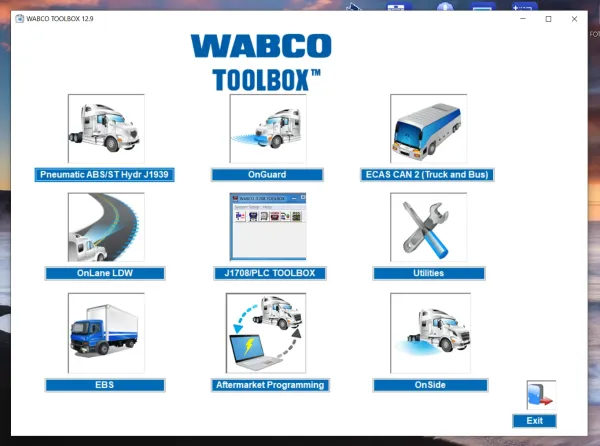

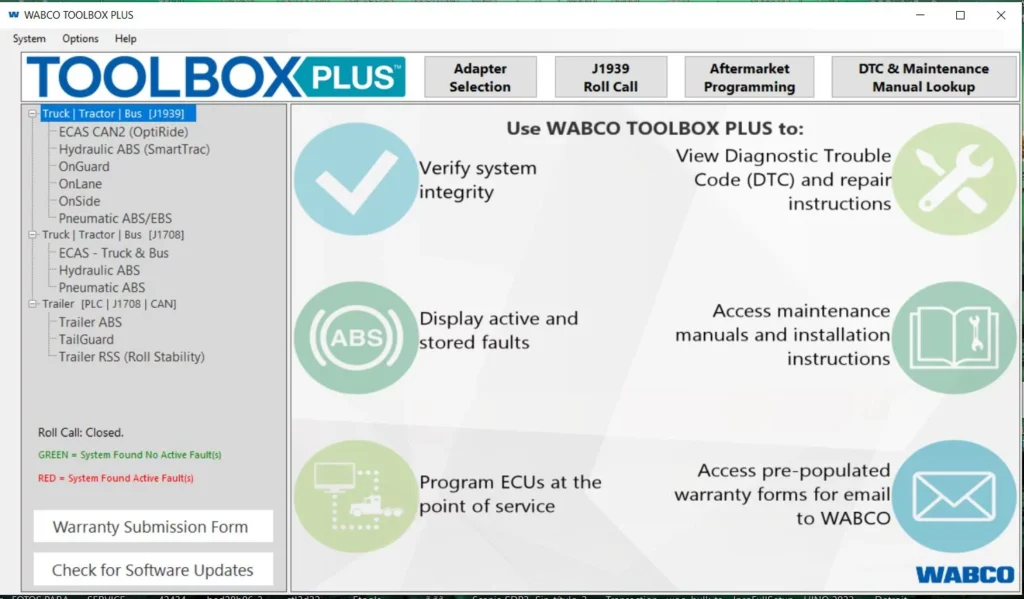

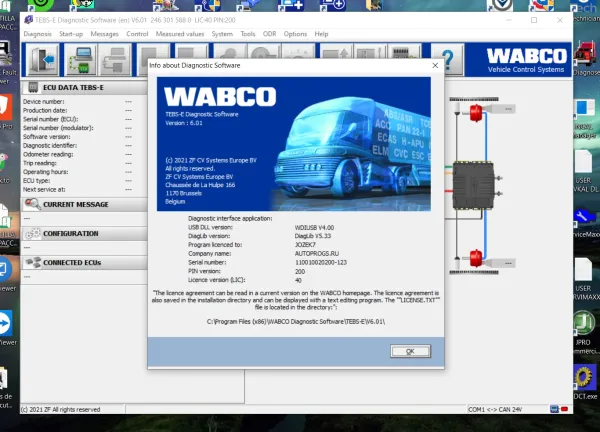

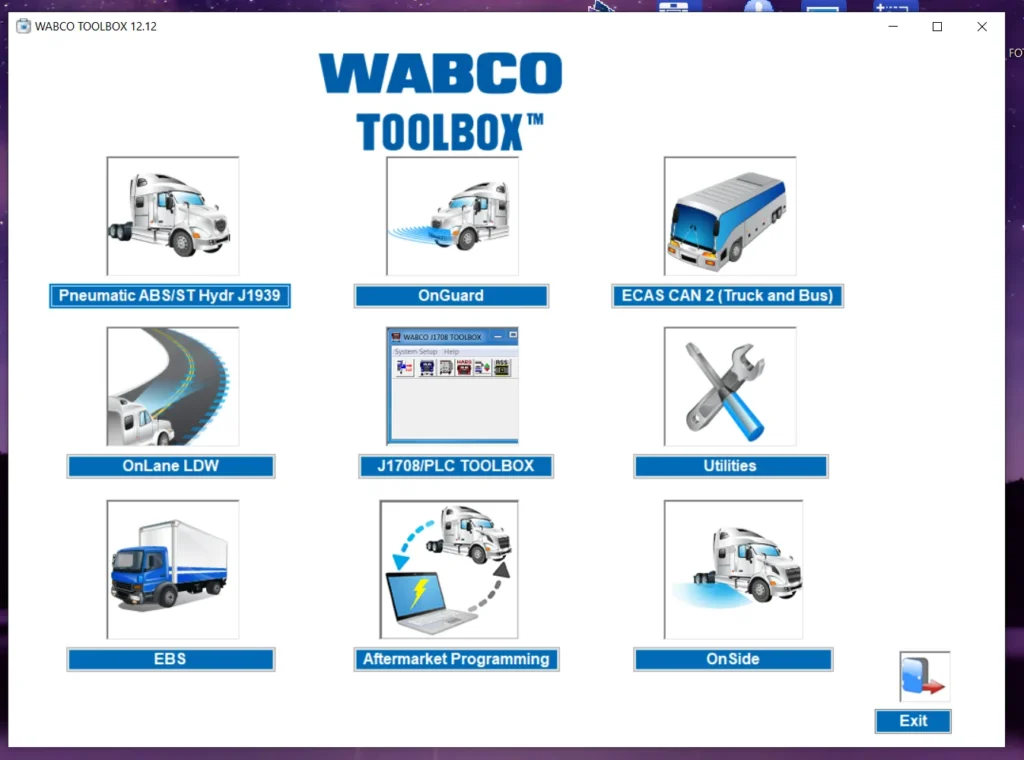

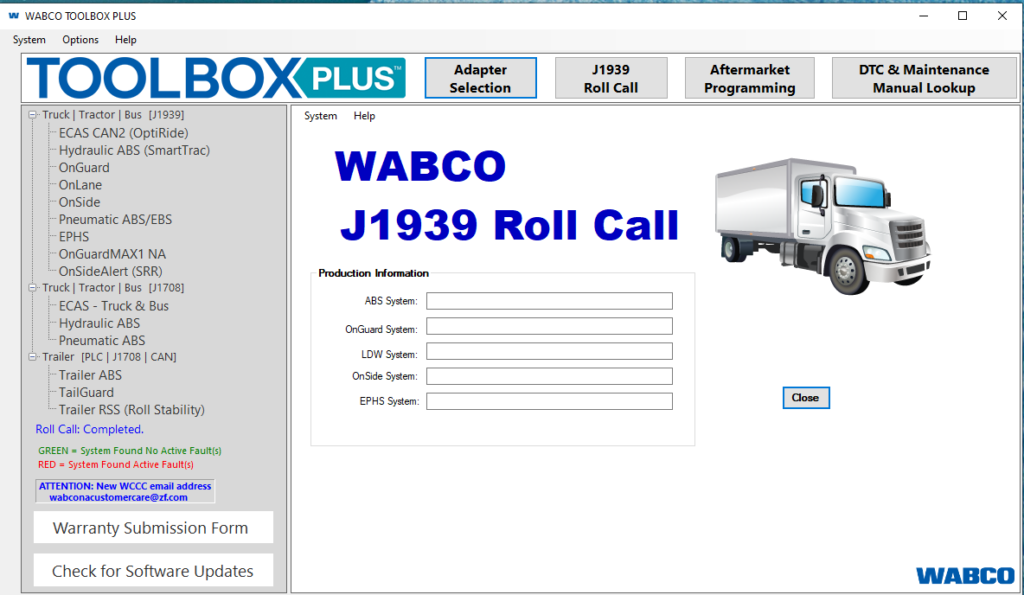

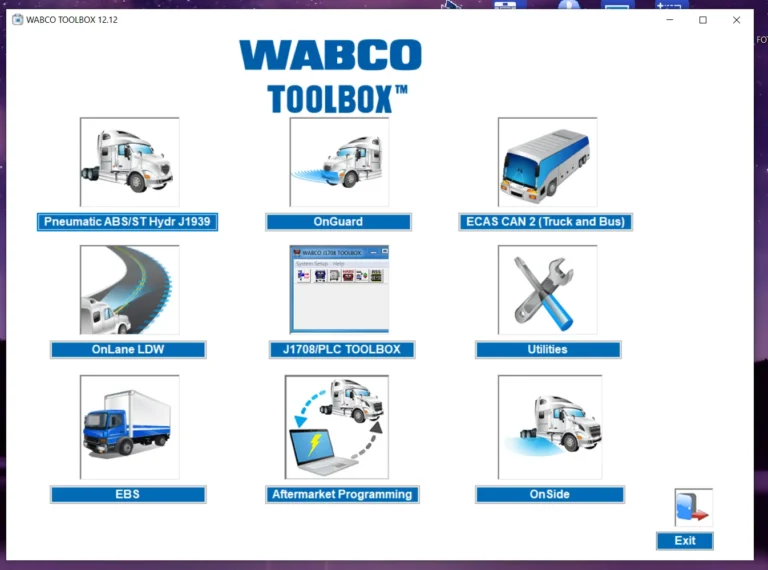

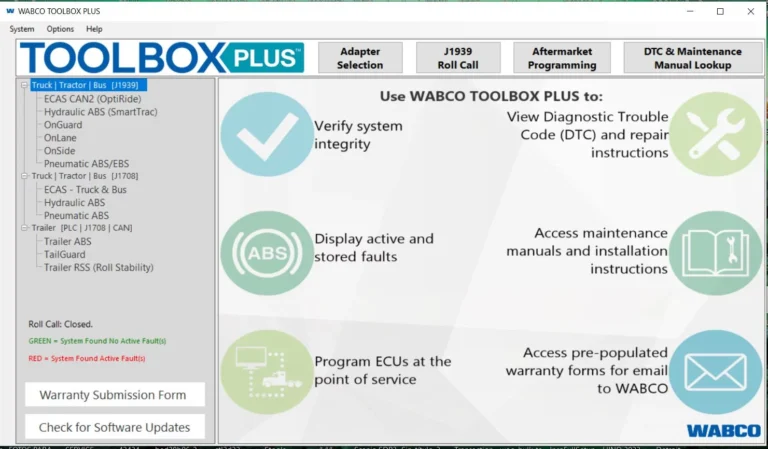

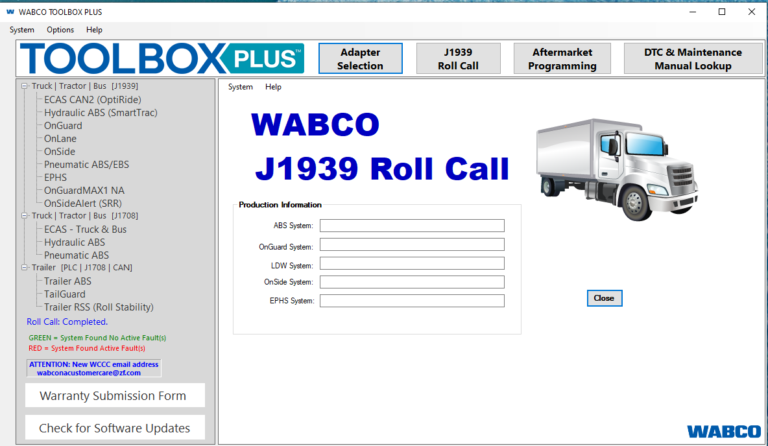

VOLVO WABCO

WABCO YALE

YALE ZF TESTMAN

ZF TESTMAN

Reviews

Clear filtersThere are no reviews yet.